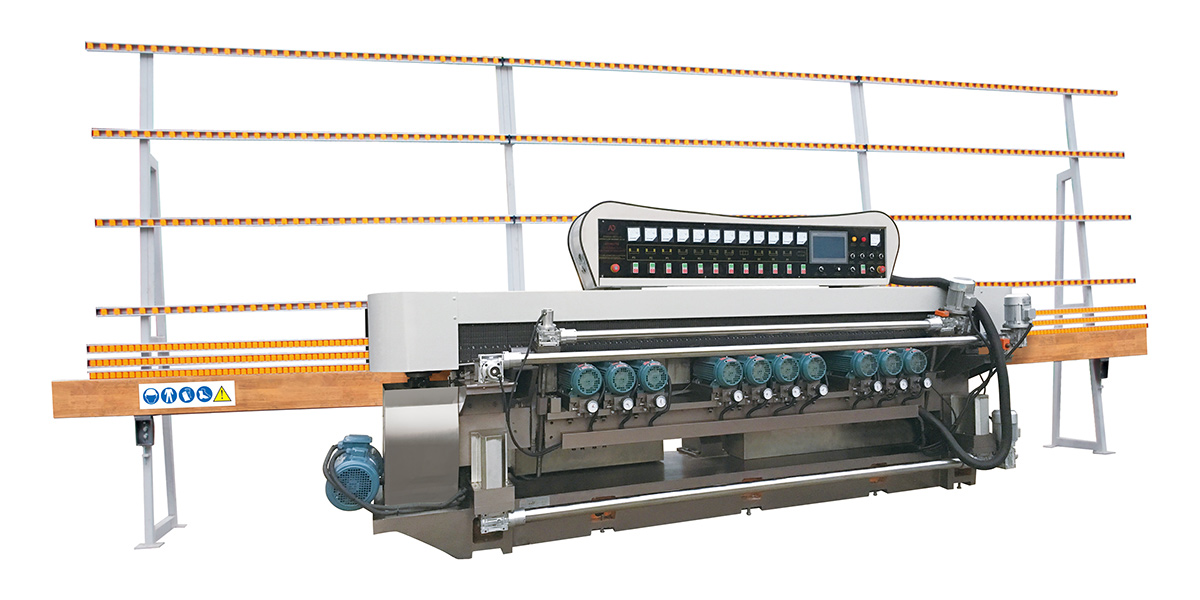

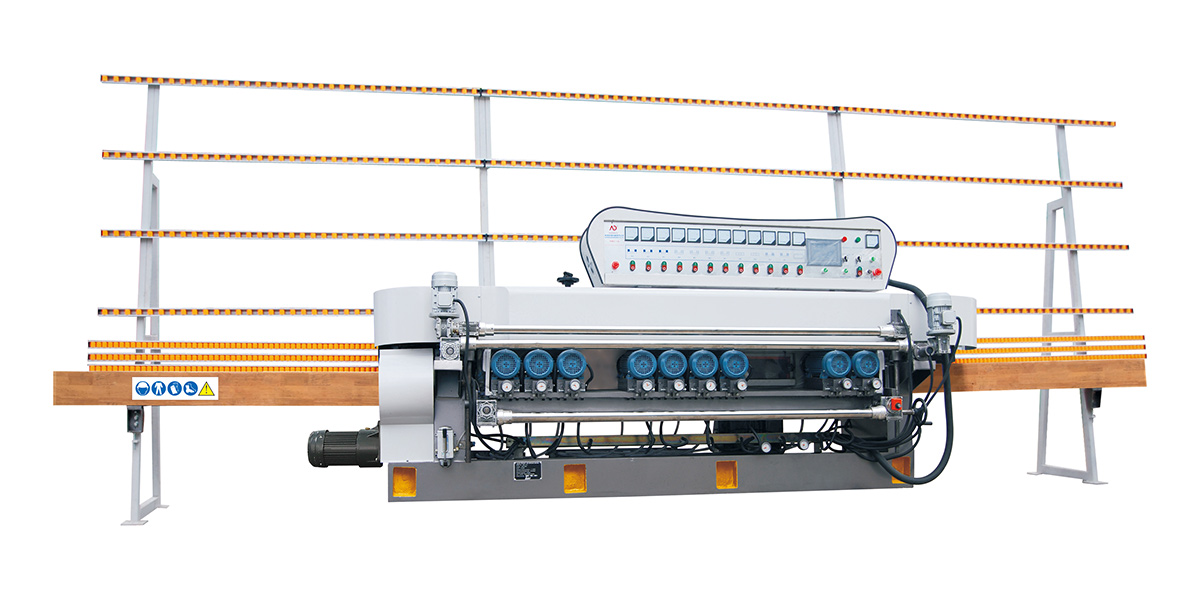

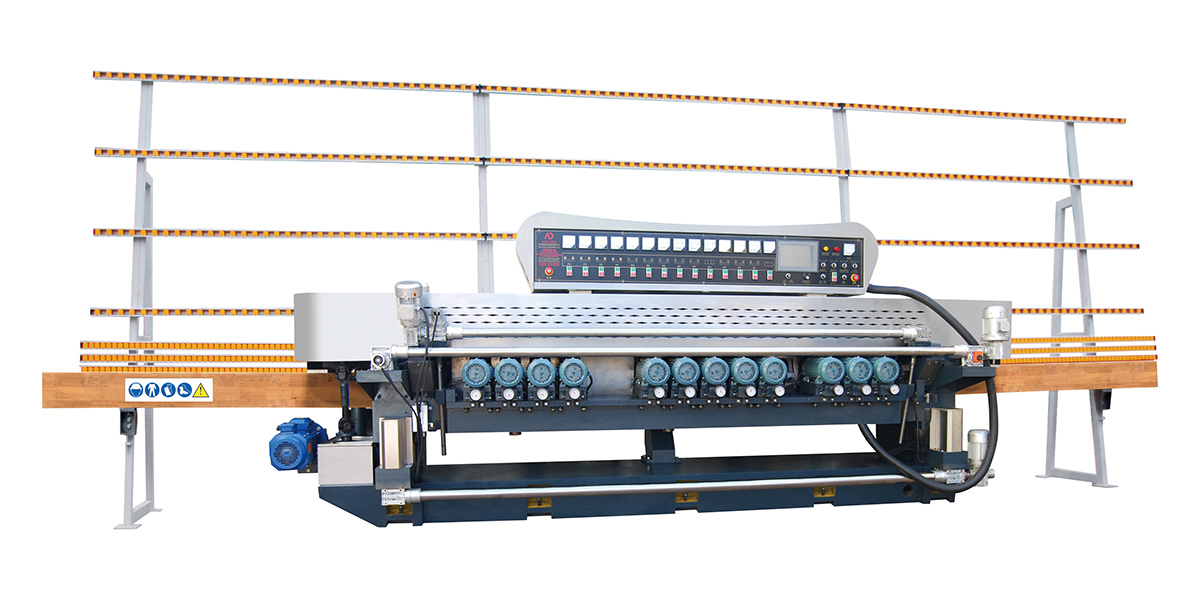

13 Motors Glass Lifting Beveling Machine

- Product Information

13 Motors Glass Lifting Beveling Machine is a high-precision and high-efficiency glass deep processing equipment, mainly used for grinding and polishing the bevel and bottom edge of flat glass. The equipment realizes multi-angle beveling, grinding and mirror polishing of the glass edge through the precise cooperation of 13 independent motors, ensuring that the glass edge is smooth and flawless, meeting the high requirements for glass quality in architectural decoration, home appliances, lenses, furniture and other fields. The whole machine adopts advanced lifting structure design and is equipped with intelligent control system. It can adapt to glass workpieces of different thicknesses and sizes. It has strong stability and convenient operation. It is an important equipment in the modern glass processing industry.

Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADXM481B |

| Voltage | 380V/50Hz |

| Power | 30kw |

| Bevel angle | 3°-45° |

| Max bevel width | 60mm |

| Glass thickness | 3-19mm |

| Feeding speed | 0.5-9m/min |

| Min size | 20×20mm |

| Weight of machine | 6800kg |

| Overall size | 8500×2500×1300mm |

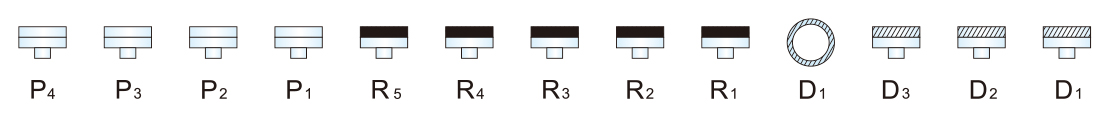

Position of Wheels:

Core Features:

13 independent motor drive system:

The machine is equipped with 13 high-performance motors, of which the first 6 motors are used for rough grinding and fine grinding of bevels, the 7th group is used for bottom grinding, and the last 6 groups are used for bevel polishing. Each motor uses 2.2kW-4.0kW industrial-grade variable frequency motors to ensure sufficient cutting force and durability. Multi-motor segmented control greatly improves processing efficiency and precision, and avoids the problem of interference between different functions in integrated motor models.

Lifting support structure:

Adopting servo-controlled lifting rail system, it can be flexibly lifted and lowered in the range of 3mm~25mm according to the thickness of glass, and can meet the bevel processing requirements of glass of different specifications. The lifting part adopts high-strength alloy steel rail and screw drive system to ensure smooth lifting and shaking, and improve the quality of the processed surface.

Adjustable bevel angle design:

Supports bevel angle adjustment from **3° to 45°**, flexible operation, and meets diverse decoration and industrial needs. The angle adjustment adopts handwheel or automatic control method, with angle scale or digital display, the adjustment process is accurate and intuitive, suitable for glass processing with complex shapes.

High-precision conveying system:

The conveying part adopts high wear-resistant rubber wheel plus stainless steel chain transmission structure, with variable frequency speed regulation motor to ensure smooth advancement of glass. The conveying speed has a wide adjustable range, usually 0.5~6.0 m/min, which can be flexibly set according to the thickness of the workpiece and grinding requirements to improve the overall processing rhythm and efficiency.

Intelligent operating system:

Equipped with PLC control system and touch operation interface, it can realize one-button start, data setting, fault alarm and real-time monitoring. Some models can be equipped with industrial remote diagnosis module to realize remote maintenance and program upgrade, reduce downtime and improve ease of use.

Efficient cooling system:

Each set of grinding wheels is equipped with an independent automatic water supply cooling system, which effectively reduces heat accumulation during processing, protects the glass from heat explosion, and prolongs the service life of the grinding wheel. The water channel adopts stainless steel pipes and is equipped with a filtration system to avoid blockage and water pollution.

Environmental protection and safety guarantee:

The equipment shell adopts waterproof and dustproof design, and the key parts are equipped with transparent protective cover and emergency stop button, which is safer to operate. It can be equipped with water circulation treatment system and dust removal device to meet environmental protection production standards.

Typical Application Scenarios:

1.Deep processing of architectural glass:

In projects such as building curtain walls, high-end doors and windows, partition walls, etc., the safety and aesthetics of the glass edges are extremely high. 13 motor glass beveling machine can achieve mirror-grade polished bevels, improve the overall appearance and strength of glass, and is widely used in glass decoration processing in office buildings, high-end residences and public buildings.

2.Home decoration glass manufacturing:

Various types of furniture such as coffee tables, dining tables, cabinets, TV background walls, etc. use a large amount of decorative glass with smooth edges. The machine's efficient fine grinding capability makes it play an important role in the home decoration glass processing industry, especially suitable for batch standardized customization scenarios.

3.Lenses and art glass:

For products such as bathroom mirrors, makeup mirrors, and art hanging mirrors that require beveled edges, 13 motor beveling machines can complete high-precision, burr-free beveling processing, meet the strict requirements for gloss and edge consistency, and widely serve lens manufacturing companies and handicraft processing factories.

4.Electrical panel and display glass manufacturing:

Including home appliances such as TV glass, touch screens, refrigerator panels, etc., the accuracy of glass corner processing is high to avoid the impact of dimensional errors or burrs on the performance of the whole machine after assembly. 13 motor beveling machines can accurately achieve process standards and support large-scale continuous processing.

Glass deep processing service factory (OEM/ODM): Small and medium-sized glass deep processing enterprises and OEM factories usually receive a variety of customer orders and have high requirements for flexibility and versatility. The 13 motor model has a good adjustment range and compatibility, and can quickly switch processing tasks of different angles and sizes, greatly improving order response speed and comprehensive processing capabilities.