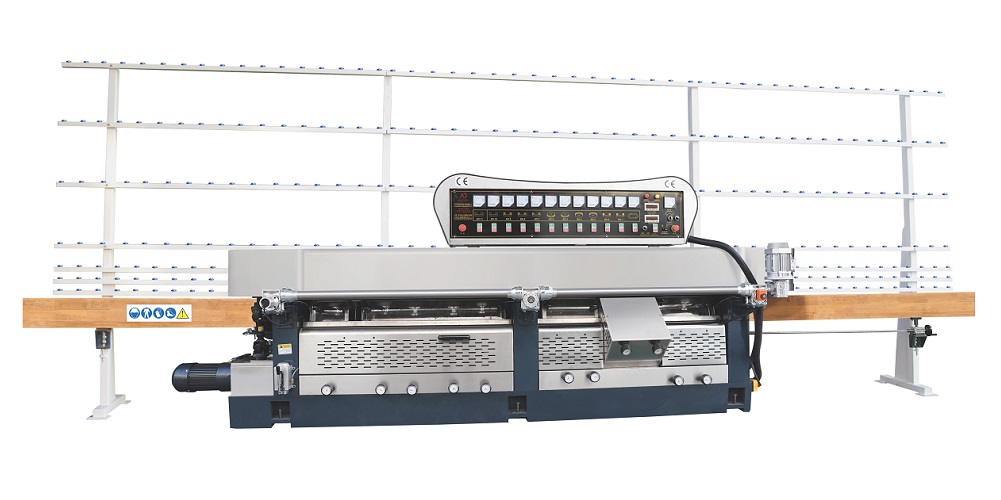

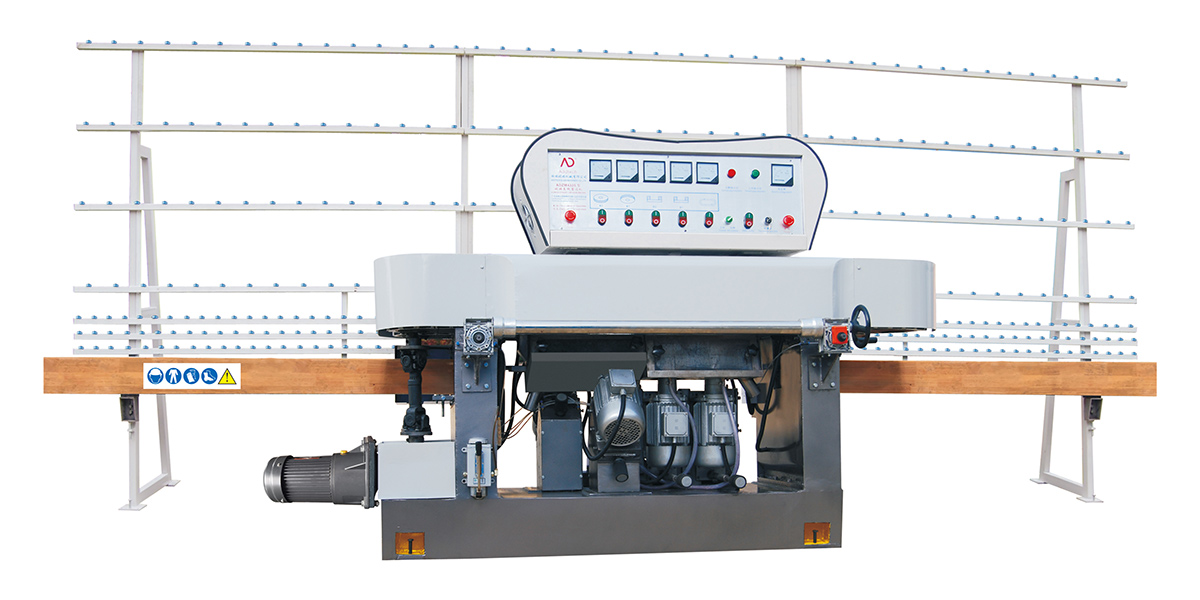

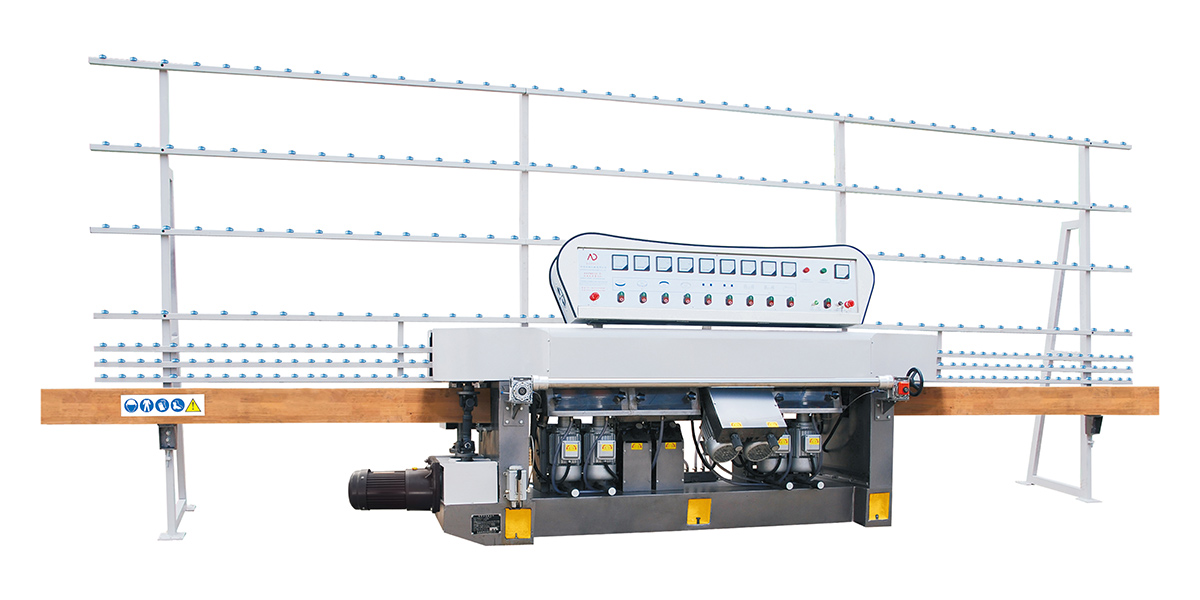

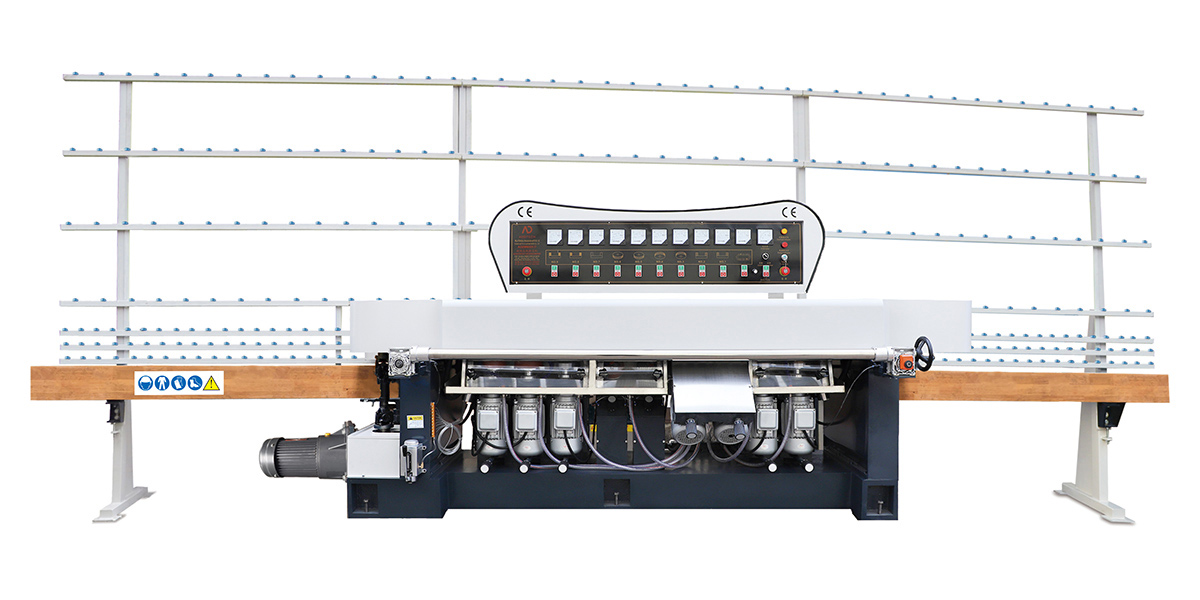

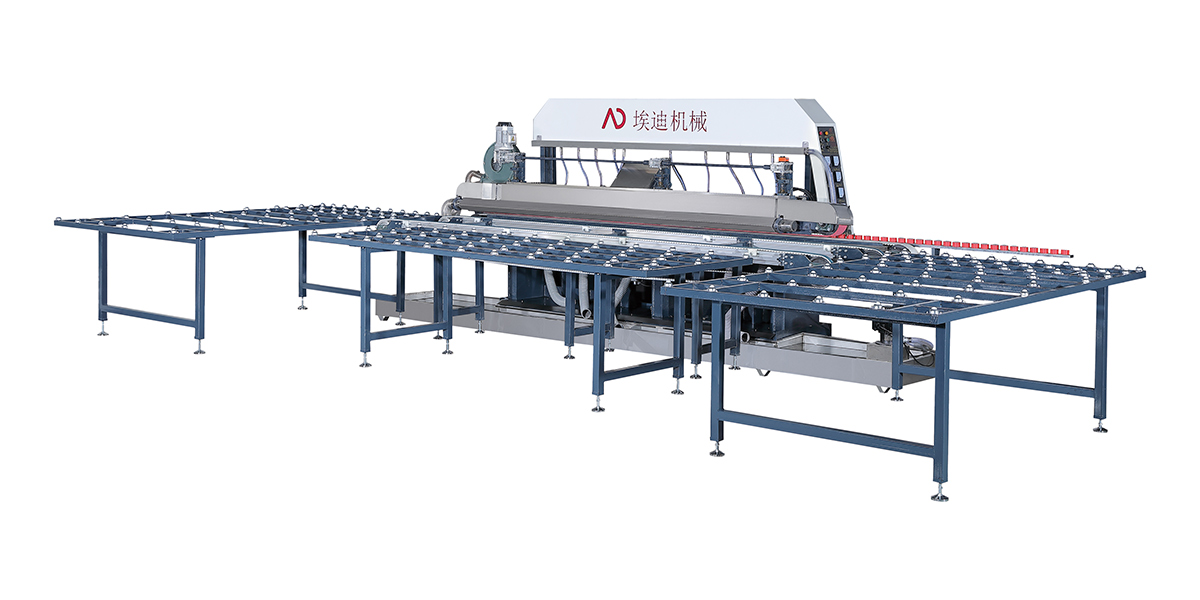

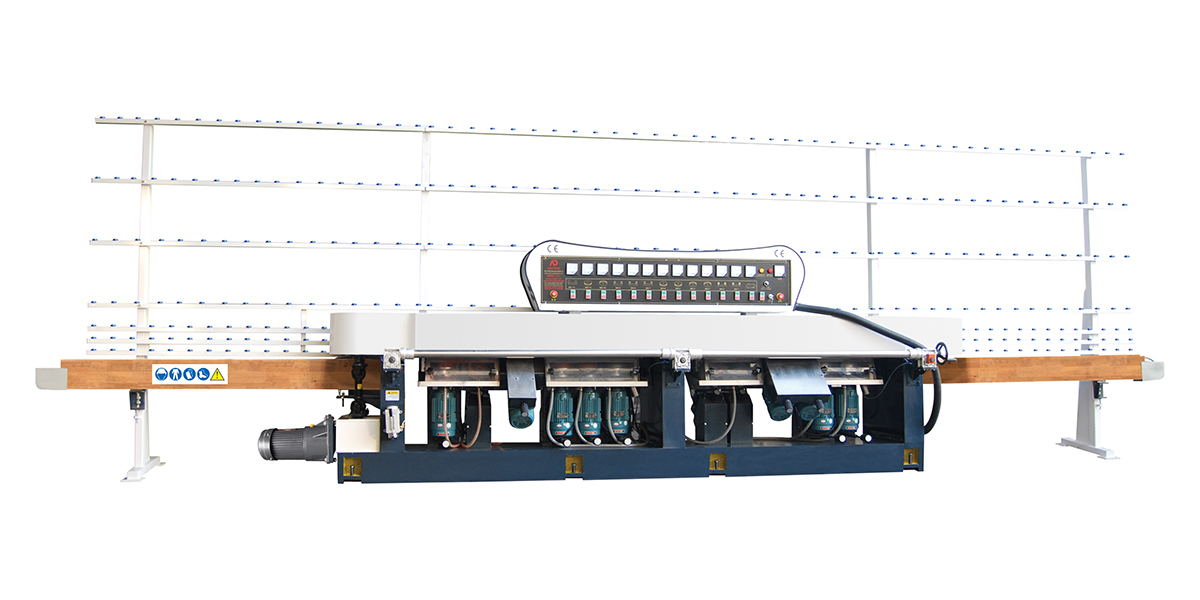

Glass Edging Machine

The glass fabrication industry must have Glass Edging Machines since they are meant to refine and finish the edges of glass products with accuracy and efficiency. In different fields, these devices play a crucial role in improving the beauty and protection of glass including decorative glasses as well as architectural glasses.

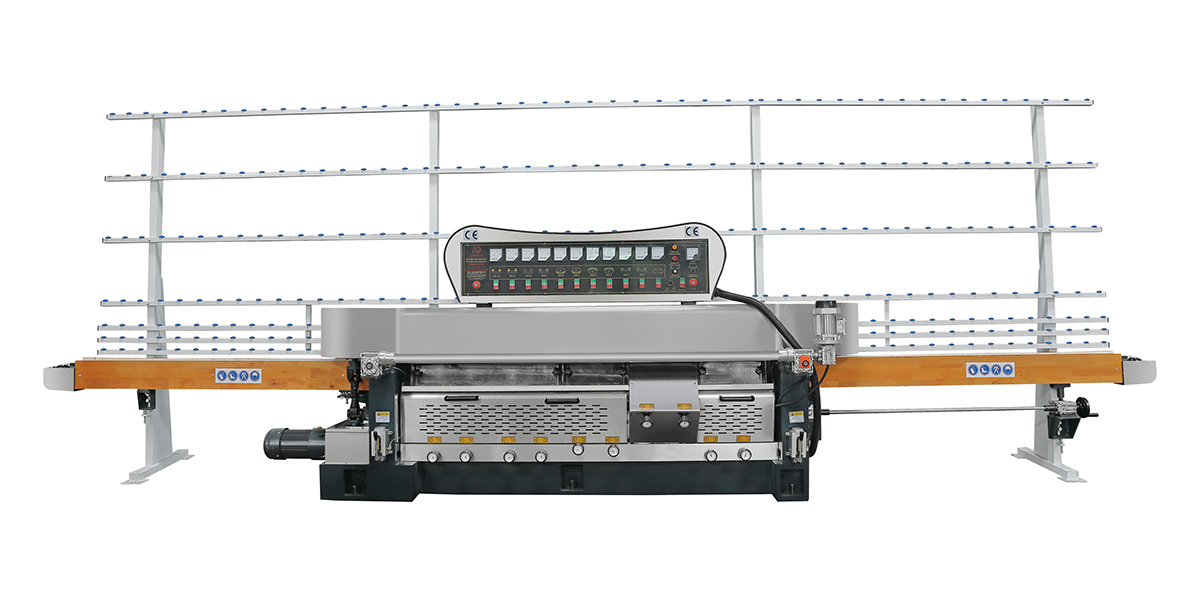

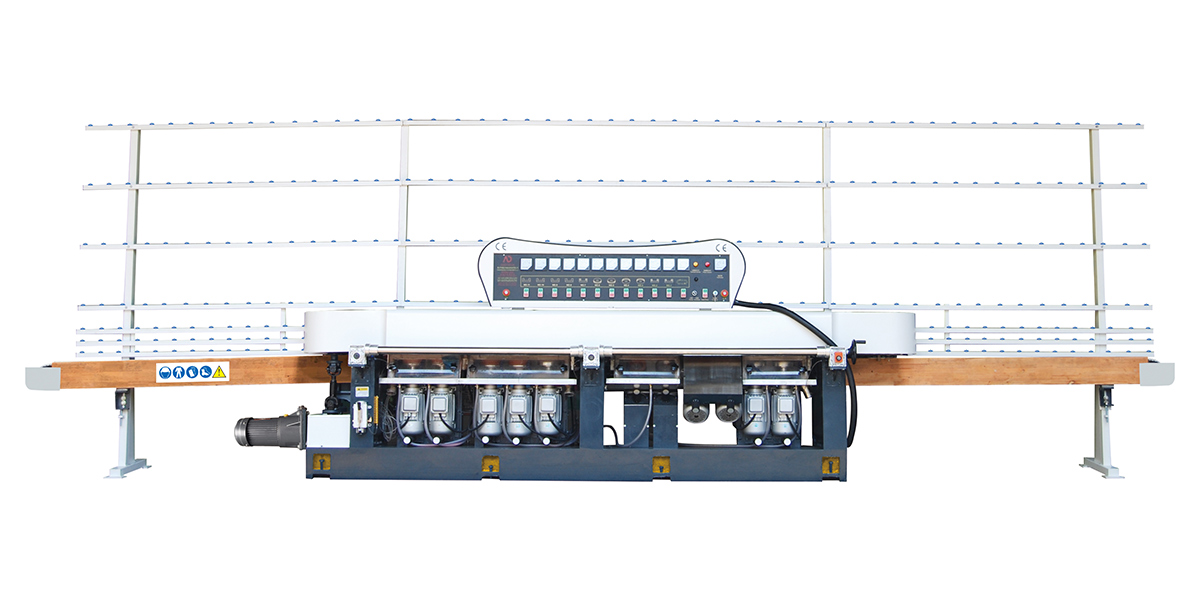

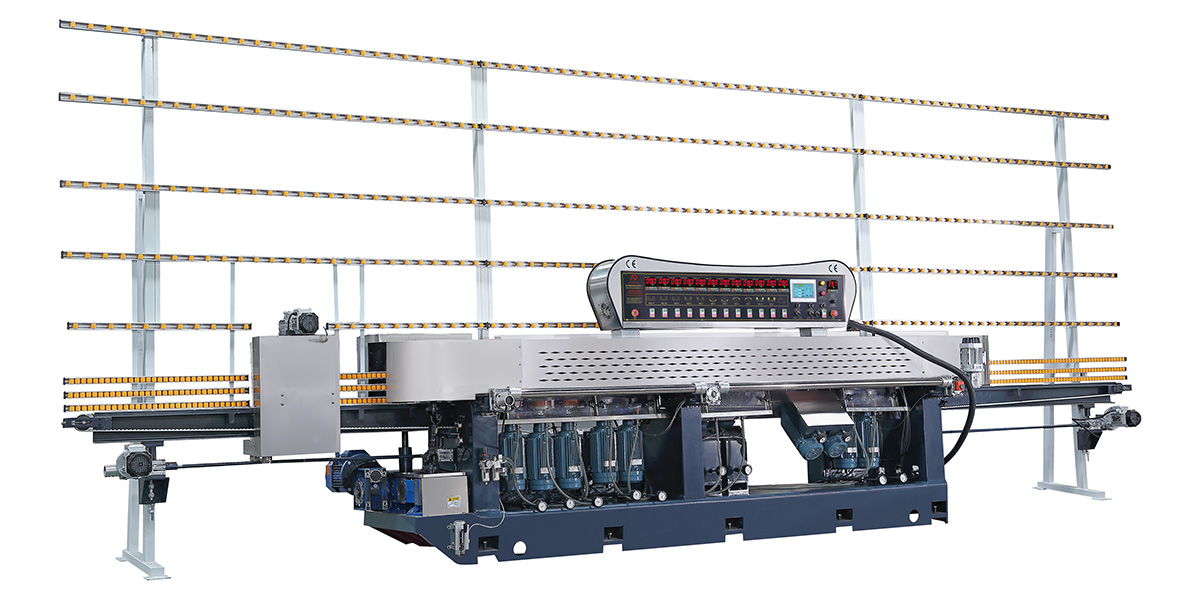

These Glass Edging Machines have the capacity to handle various types and thicknesses of glasses hence making them suitable for numerous projects. The results obtained from using Glass Edging Machines on either small size or large size materials will always be consistent as well as being of high quality. Different processes such as flat, pencil, bevel, ogee can be carried out by a Glass Edging Machine which is equipped with state-of-the-art technology for accurate edge finishing. This allows one to have a variety of designs’ need met.

A good number of modern-day typologies come with faster speeds that ensure that manufacturers do not fail in terms of time when dealing with tight production schedules. Because there are automated procedures which minimize manual labor then a lot can be done within a short period. Made from strong materials and components, these Glass Edging Machines usually last long in use over time without breaking down easily. These Glass Edging Machines are therefore designed in such manner that they can work throughout at satisfying demands before any breakdown occurs.

Glass furniture, mirrors or decorative elements can also become finer with the help of these Glass Edging Machine which are often used in interior design. By ensuring smoothness on glass windows, doors, partitions or facades via nice looking edges it adds up to their safety factor thus complementing aesthetics too.

Glass processing and manufacturing businesses cannot do without Glass Edging Machines. They are indispensable in various sectors due to their ability to produce edges that are highly precise, efficient and of high-quality. This would also enable the firms improve on their profitability by investing into modern technologies that assist in making accurate product finishing thereby increasing both production capacity and output.

Get ADDTECH Glass Edging Machine to Delight Your Customers

Glass Edging Machines are crucial instruments for attaining accuracy and sleekness in glass processing. They supply adaptable methods to bevel, polish and grind the edges of glasses, thus improving both safety and beauty. They serve as very important machines used for various purposes.

What types of glass can the Glass Edging Machine handle?

Our Glass Edging Machine is versatile and can handle a wide range of glass types, including tempered glass, laminated glass, low-E glass, and more. It's designed to accommodate different thicknesses and sizes, ensuring precision and efficiency in every project.

How does the Glass Edging Machine ensure safety during operation?

Safety is our top priority. The Glass Edging Machine is equipped with advanced safety features such as emergency stop buttons, protective guards, and automatic shutdown systems in case of malfunction. Additionally, we provide comprehensive training and user manuals to ensure safe operation.

What maintenance is required for the Glass Edging Machine?

Regular maintenance is essential for optimal performance. This includes cleaning the machine regularly, checking and replacing worn-out parts, lubricating moving components, and inspecting the electrical system. Our support team is available to assist with maintenance schedules and troubleshooting.

Can the Glass Edging Machine be customized to meet specific production needs?

Yes, we offer customization options to suit various production requirements. Whether it's adjusting the speed, edge profile, or integrating with other equipment, our team can tailor the machine to fit your specific needs and maximize productivity.