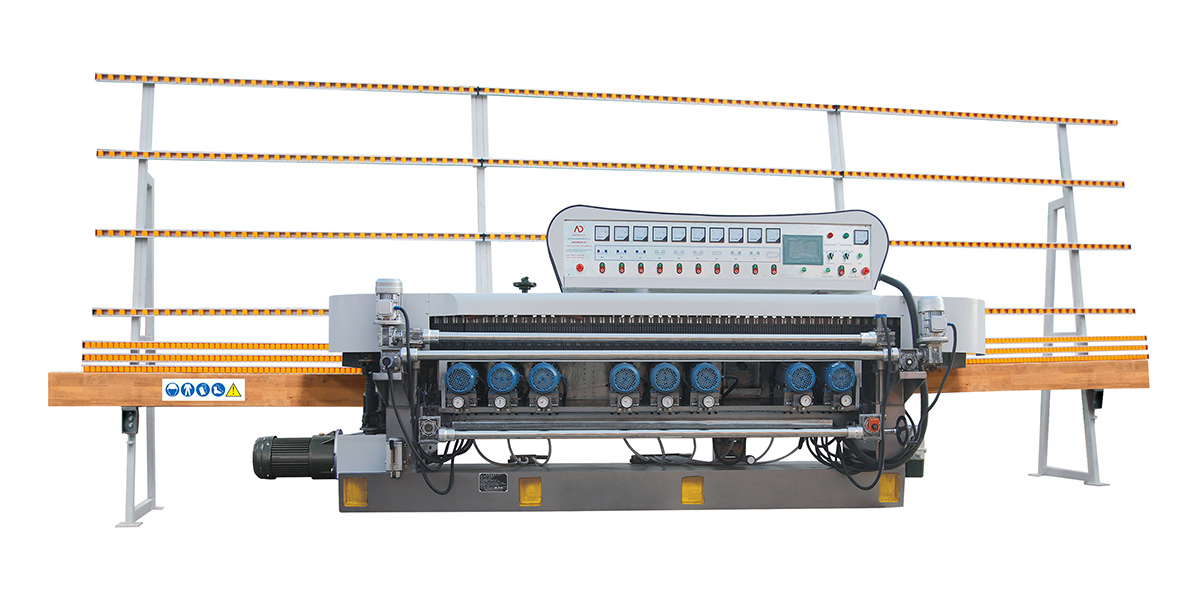

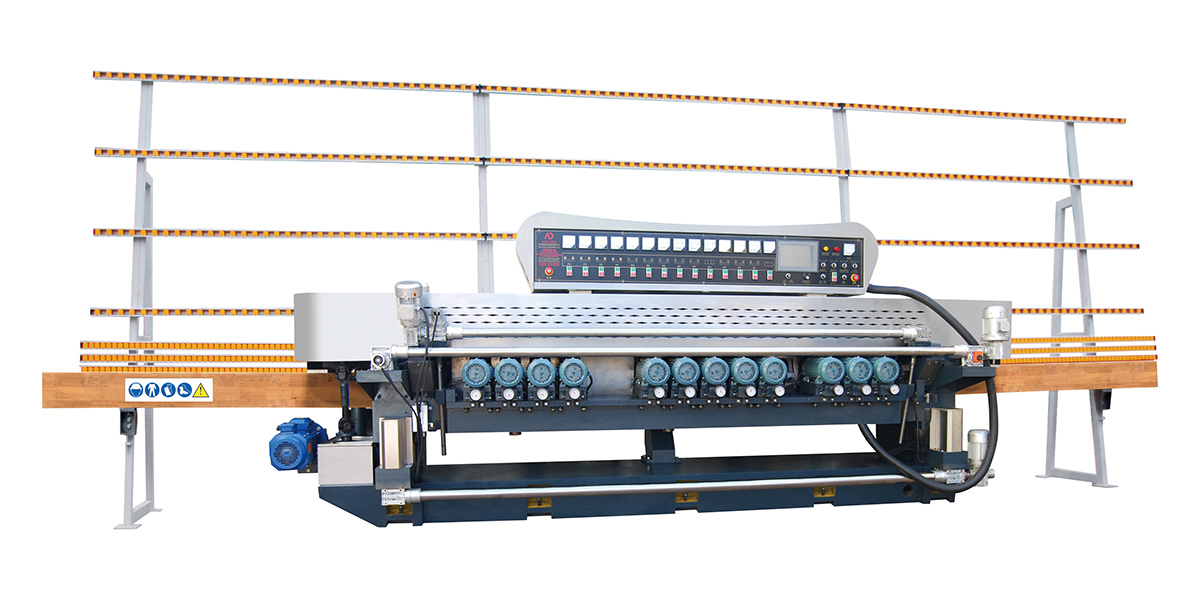

Glass Beveling Machine

Glass Beveling Machines are key tools in the glass industry responsible for forming angular edges and ornamental finishes on glass panels. These machines are precise and effective enabling them to suit a wide range of applications such as large scale industrial usage and custom glasswork.

Our Glass Beveling Machines have technology that enables them to produce accurate and smooth sloping edges which assists in enhancing not only aesthetic value but also structural integrity of the glass. These Glass Beveling Machines can handle different types of glasses like flat, mirror, decorative, etc. They come in various sizes and thicknesses thus making them suitable for both mass customization projects and standard.

The Glass Beveling Machines we manufacture allow you to work with a fast speed yet maintain high quality throughout hence increasing production and saving costs. For beginners who want to become professionals, we have designed our beveling machinery with easy operational mechanisms including understandable controls and comfortable structure.

Our Glass Beveling Machines are built using strong materials thus last longer without maintenance so much. Assembling out of tough components these devices are able to go on round-the-clock operations.

Our customers’ desires vary from adding beauty to their products made out of glasses up to complying into some distinct properties; hence our precision as well as robustness is what makes us relevant. Consult our portfolio published online now!

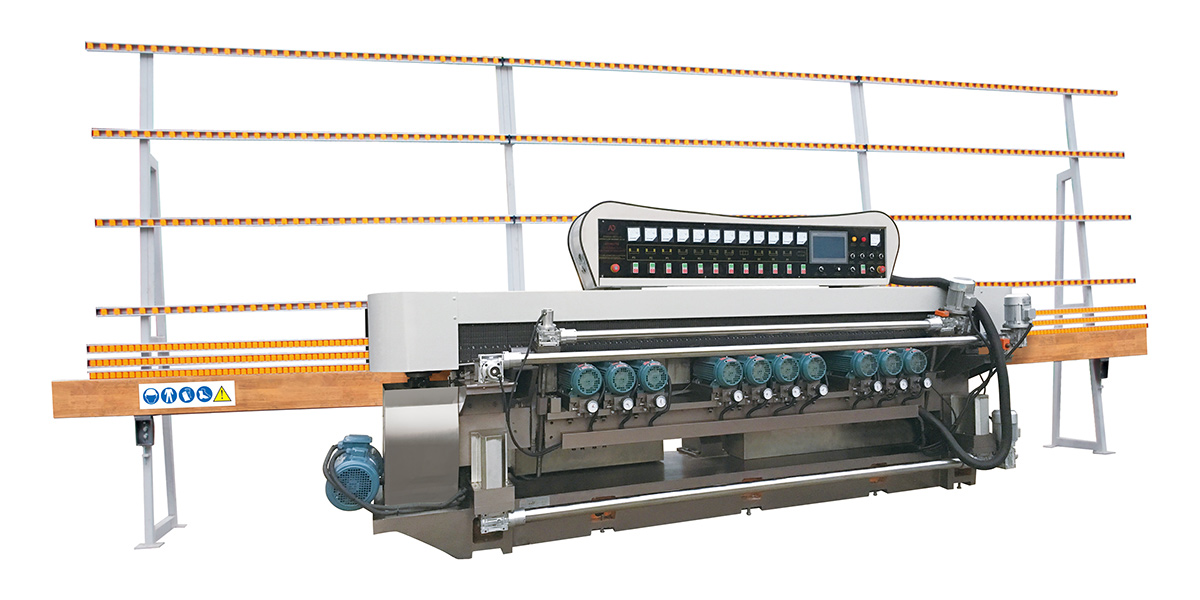

Get ADDTECH Glass Beveling Machine to Delight Your Customers

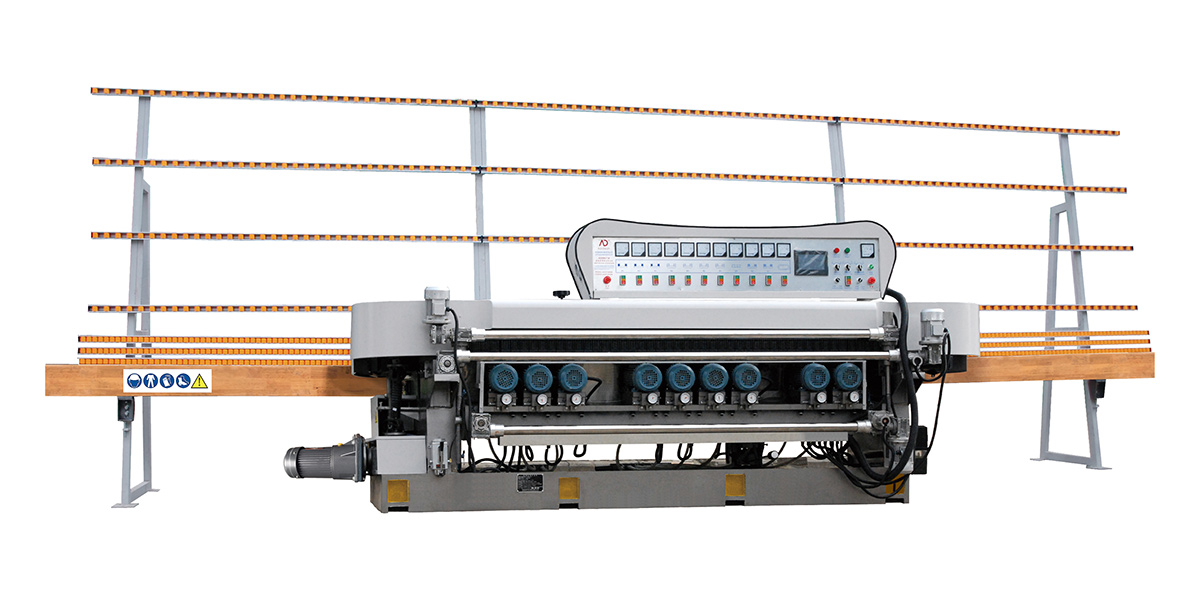

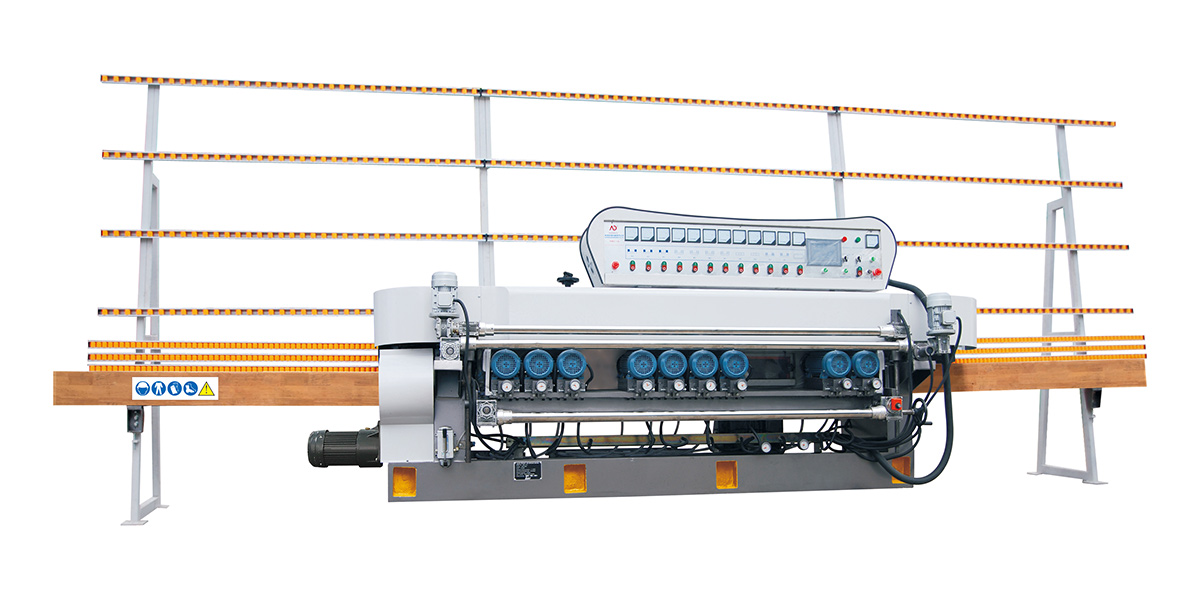

Glass Beveling Machines are important tools when it comes to giving smooth slanted sides on different glass surfaces. With our Glass Beveling Machine sizes ranging from small workshop use right through to large scale industrial production plants, they give high quality output every time they are used.

What is a Glass Beveling Machine used for?

A Glass Beveling Machine is used to create angled edges, or bevels, on glass surfaces. This process enhances the aesthetic appeal of the glass and can be used for decorative purposes in windows, mirrors, and glass furniture.

How does a Glass Beveling Machine work?

Glass Beveling Machines use abrasive wheels to grind and polish the edges of the glass at an angle. The machine operates by holding the glass in place while the wheels move across its edges, gradually creating a smooth, beveled finish.

What types of glass can be beveled with this Glass Beveling Machine?

Most Glass Beveling Machines can handle various types of glass, including tempered, laminated, and float glass. However, it's essential to check the machine specifications to ensure compatibility with the specific glass type you intend to use.

What is the maximum thickness of glass that can be beveled?

The maximum thickness a Glass Beveling Machine can handle varies depending on the model. Generally, these machines can work with glass thicknesses ranging from 3 mm to 20 mm. Always consult the machine's specifications for precise details.

What maintenance is required for a Glass Beveling Machine?

Regular maintenance is crucial to ensure the machine's optimal performance. This includes cleaning the machine after each use, checking and replacing abrasive wheels as needed, lubricating moving parts, and inspecting the machine for any signs of wear or damage.