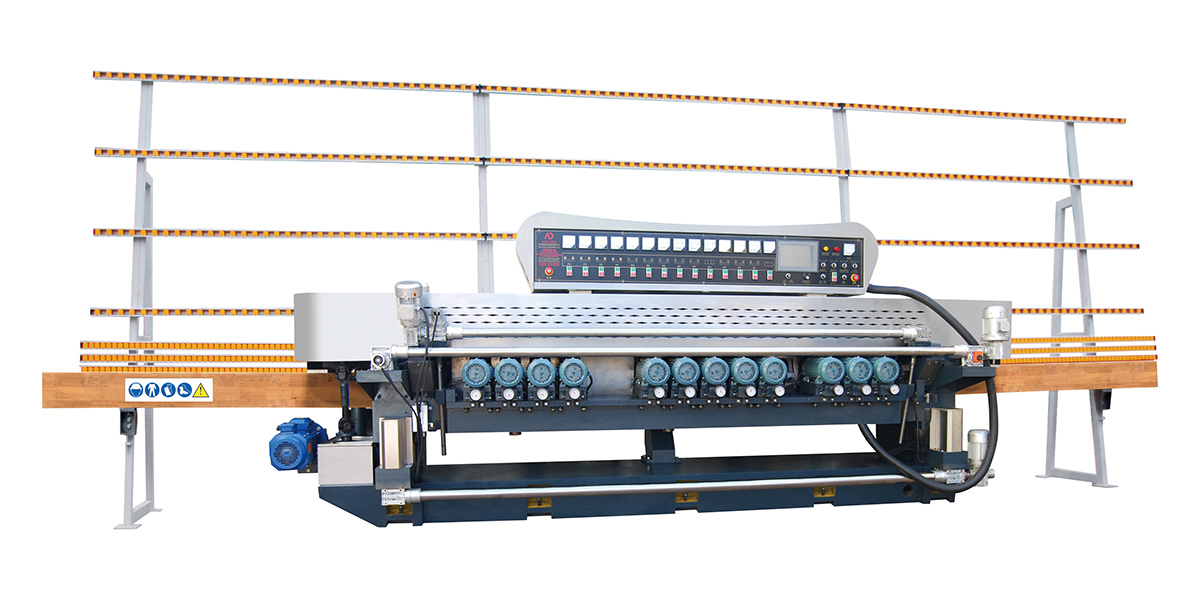

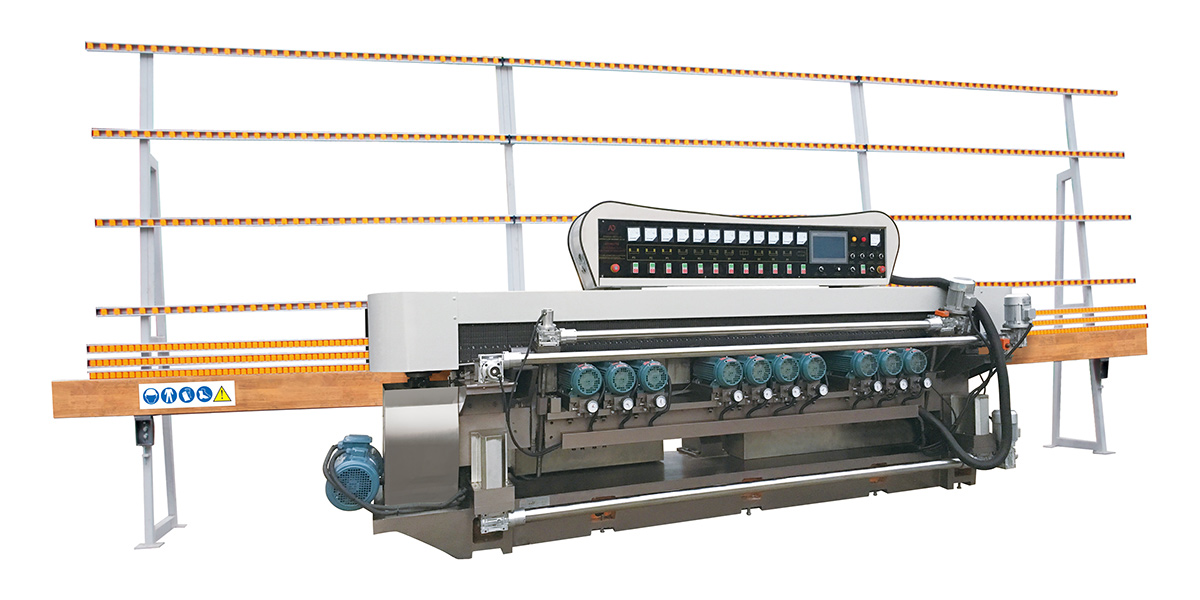

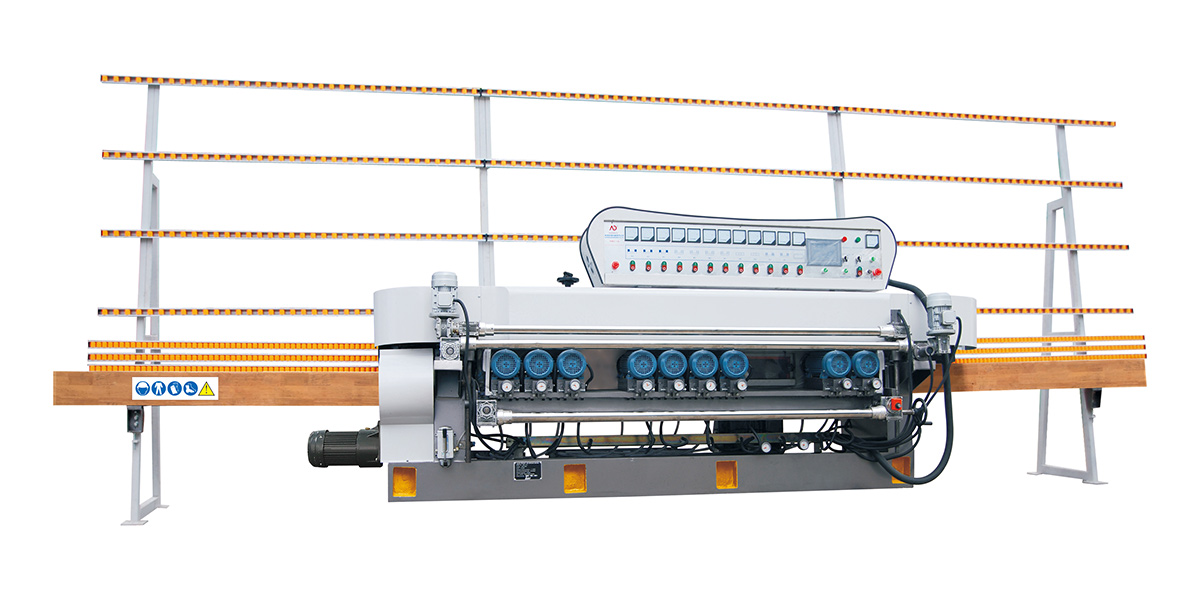

11 Motors Glass Straight Line Beveling Machine

- Product Information

11 Motors Glass Straight Line Beveling Machine is a high-precision glass processing equipment carefully built by ADDTECH. It adopts advanced design concepts and exquisite manufacturing technology to provide efficient and reliable solutions for the glass processing industry. This equipment is equipped with 11 independent motors to provide strong and stable power support for each processing link, ensuring the efficiency and accuracy of the processing process. The main structure of the equipment is made of high-strength steel, and after fine processing and strict quality inspection, the sturdiness and stability of the equipment are guaranteed. Its work surface is flat and smooth, which can meet the processing needs of glass of different sizes and thicknesses, and provides a good foundation for the fixing and processing of glass. During the processing process, the equipment realizes the automation of a series of processes such as rough grinding, fine grinding, polishing and bottom edge processing of glass through a precise control system.

11 Motors Glass Straight Line Beveling Machine Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADXM371A |

| Voltage | 380V/50Hz |

| Power | 24.5kw |

| Bevel angle | 0°-35° |

| Max bevel width | 40mm |

| Glass thickness | 3-19mm |

| Feeding speed | 0.5-7m/min |

| Min size | 30×30mm |

| Weight of machine | 4000kg |

| Overall size | 7300×2500×1300mm |

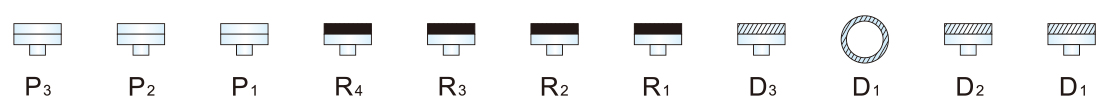

11 Motors Glass Straight Line Beveling Machine Position of Wheels:

11 Motors Glass Straight Line Beveling Machine Features:

Efficient power:

11 Motors Glass Straight Line Beveling Machine has 11 motors to provide strong power for the operation of the equipment. These motors work together to ensure that each process in the glass processing can be carried out efficiently, whether it is rough grinding, fine grinding or polishing, it can be completed quickly, greatly improving production efficiency, meeting the needs of large-scale production of enterprises, and helping enterprises to gain an advantage in the fierce market competition.

Precision processing:

11 Motors Glass Straight Line Beveling Machine adopts advanced processing technology to achieve high-precision glass processing. Its high processing accuracy can ensure that the edge of the glass is flat and smooth, and the size is accurate, meeting the strict requirements of different customers for glass quality. The precise processing capability not only improves the appearance quality of the product, but also improves the practicality and safety of the product, and is suitable for various application scenarios that require high precision in glass processing.

Multi-function integration:

11 Motors Glass Straight Line Beveling Machine integrates multiple functions in one, and can complete multiple processes such as rough grinding, fine grinding, polishing and bottom edge processing at one time. This multifunctional integrated design reduces the number of glass transfers between different devices, reduces losses and errors during processing, improves processing efficiency and product quality, and also saves the company's equipment investment costs and production space.

Stable transmission:

The 11 Motors Glass Straight Line Beveling Machine adopts a continuously variable mechanical transmission mechanism, which can flexibly adjust the working speed according to different processing requirements. This transmission method runs smoothly and has low noise, which can ensure the stability and reliability of the equipment during long-term operation, reduce the occurrence of equipment failures, extend the service life of the equipment, and provide continuous and stable production support for enterprises.

Sturdy and durable:

All pressing plates are made of thick steel plates, making the 11 Motors Glass Straight Line Beveling Machine more sturdy and durable. The use of thick steel plates not only enhances the structural strength of the equipment, enabling it to withstand greater processing loads, but also improves the stability and reliability of the equipment, ensuring that it can maintain good working performance even in a high-intensity production environment, reducing production interruptions caused by equipment damage, and reducing the company's maintenance costs.

Convenient operation:

The operation interface of the 11 Motors Glass Straight Line Beveling Machine is simple and easy to use. Users can complete various processing settings and adjustments through simple operations, and can master the use of the equipment without complex training. The convenient operation method improves production efficiency, reduces the difficulty of operation, enables enterprises to quickly put into production, and improve production efficiency.

Strong adaptability:

11 Motors Glass Straight Line Beveling Machine can adapt to the processing needs of glass of different sizes and thicknesses. Its front pressure plate can be adjusted up and down according to the size of the glass to ensure that the glass can be well fixed and supported during the processing process, thereby realizing efficient processing of various specifications of glass and meeting the diverse needs of different customers for glass processing.

High practicality:

The design of 11 Motors Glass Straight Line Beveling Machine fully considers various needs in actual production and has high practicality. It has a wide processing range and can meet the requirements of various glass processing processes and is suitable for different production scenarios. At the same time, the maintenance of the equipment is simple and convenient, which reduces the maintenance cost of the enterprise, improves the use efficiency of the equipment, and creates more value for the enterprise.

11 Motors Glass Straight Line Beveling Machine Application:

Architectural glass processing:

In the field of construction, 11 Motors Glass Straight Line Beveling Machine can be used to process various architectural glass, such as door and window glass, curtain wall glass, etc. By chamfering and grinding the glass, the edge is smoother and more beautiful, while improving the safety and sealing of the glass, meeting the requirements of the construction industry for glass quality and aesthetics, and adding beauty and safety to the building.

Furniture glass processing:

11 Motors Glass Straight Line Beveling Machine can perform fine processing on furniture glass, such as coffee table glass, dining table glass, cabinet glass, etc. The processed glass has smooth edges without burrs and precise dimensions, which can perfectly fit with other parts of the furniture, improve the overall quality and aesthetics of the furniture, meet consumers' demand for high-quality furniture, and provide furniture manufacturers with high-quality glass processing solutions.

Decorative glass processing:

In the field of decoration, 11 Motors Glass Straight Line Beveling Machine can process various decorative glasses, such as mirrors, glass partitions, glass screens, etc. Its high-precision processing capability can ensure that the edges of the glass are neat and smooth, and the patterns and patterns are clear and beautiful, adding a unique artistic effect to interior decoration, meeting people's demand for personalized and high-quality decoration, and improving the beauty and grade of the decorative space.

Automotive glass processing:

For the processing of automotive glass, 11 Motors Glass Straight Line Beveling Machine can achieve efficient processing of automotive windshields, window glass, etc. Its precise processing accuracy can ensure that the size and shape of the glass meet the requirements of automobile manufacturing, while improving the safety and reliability of the glass, ensuring the safety and comfort of the car during driving, and providing reliable glass processing support for automobile manufacturers.

Electronic glass processing:

In the field of electronics, 11 Motors Glass Straight Line Beveling Machine can be used to process glass for electronic equipment, such as mobile phone screen glass, computer monitor glass, etc. Its high-precision processing capability can ensure the surface quality and dimensional accuracy of the glass, meet the requirements of electronic equipment for high precision and high flatness of glass, improve the display effect and service life of electronic products, and provide high-quality glass processing services for electronic equipment manufacturers.

Handicraft glass processing:

11 Motors Glass Straight Line Beveling Machine is also suitable for the processing of handicraft glass, such as glass ornaments, glass lamps, etc. Its multifunctional integrated design can realize a variety of glass processing techniques, making the edges of handicraft glass smoother and more beautiful, and the patterns and shapes more refined, thereby enhancing the artistic value and appreciation of handicrafts, meeting the needs of handicraft manufacturers for high-quality glass processing, and providing exquisite glass handicrafts for the handicraft market.

11 Motors Glass Straight Line Beveling Machine Maintenance:

Daily cleaning:

1. After work every day, use a clean soft cloth or brush to clean the surface of the 11 Motors Glass Straight Line Beveling Machine to remove dust, debris and other debris to prevent dust from entering the equipment and affecting normal operation.

2. Regularly clean the dust and debris inside the equipment, especially key parts such as motors and transmission devices, keep the inside of the equipment clean and dry, and avoid equipment failure due to dust accumulation.

3. Focus on cleaning the processing area of the 11 Motors Glass Straight Line Beveling Machine to ensure that the processing platform and tool parts are clean and free of dirt, improve the processing quality and equipment life.

Regular inspection:

1. Regularly check the fasteners of the equipment, such as bolts, nuts, etc., to ensure that they are well fastened and not loose. If there is any looseness, tighten it in time to prevent unstable operation or damage of the equipment due to loose fasteners.

2. Check the electrical system of the 11 Motors Glass Straight Line Beveling Machine, including wires, cables, switches, etc., to check whether there is aging, damage, short circuit, etc. If any problems are found, they should be repaired or replaced in time to ensure the safe and reliable operation of the electrical system and avoid safety accidents caused by electrical failures.

3. Regularly check the lubrication system of the equipment to check whether the oil level and oil quality of the lubricating oil are normal. If there is any shortage or deterioration, the lubricating oil should be replenished or replaced in time to ensure that the transmission parts of the equipment are well lubricated, reduce wear and extend the service life of the equipment.

Tool maintenance:

1. Regularly check the wear of the 11 Motors Glass Straight Line Beveling Machine tool, such as blunt blades, notches, etc., and replace or sharpen the tool in time to ensure the sharpness and processing accuracy of the tool. Severely worn tools will affect the processing quality and even cause equipment failure.

2. When replacing the tool, strictly follow the operation manual of the equipment to ensure that the tool is installed correctly and firmly. Improperly installed tools may loosen or fall off during processing, causing equipment damage or safety accidents.

3. Store the tool properly to avoid the impact of adverse environments such as collision and humidity, maintain the integrity of the tool, and extend the service life of the tool.

Transmission system maintenance:

1. Regularly check the tightness and wear of the transmission belt of 11 Motors Glass Straight Line Beveling Machine. If it is loose, it should be adjusted in time. The belt with severe wear should be replaced in time to ensure the normal operation of the transmission system and avoid equipment failure due to belt slippage or breakage.

2. Regularly check and clean the transmission gears, remove oil and debris on the surface of the gears, and check the wear of the gears. If there is abnormal wear, the gears should be repaired or replaced in time to ensure the smoothness and accuracy of the transmission.

3. Regularly lubricate and inspect the transmission shaft, bearings and other components to ensure smooth operation without abnormal noise and vibration. If abnormalities are found, they should be repaired or replaced in time to prevent the normal operation of the equipment from being affected by transmission component failure.

Electrical system maintenance:

1. Regularly check and maintain the electrical control system of 11 Motors Glass Straight Line Beveling Machine, including control panels, sensors, relays and other components, to ensure their normal operation. If there is a fault, it should be repaired or replaced in time to avoid the equipment from failing to operate normally due to electrical control system failure.

2. Check whether the grounding device of 11 Motors Glass Straight Line Beveling Machine is in good condition and ensure that the grounding resistance of the equipment meets the requirements. A good grounding device can effectively prevent equipment leakage and protect the personal safety of operators.

3. Regularly update and maintain the software of the electrical system to ensure that the control system of the equipment can operate normally and improve the intelligence level and operation efficiency of the equipment.