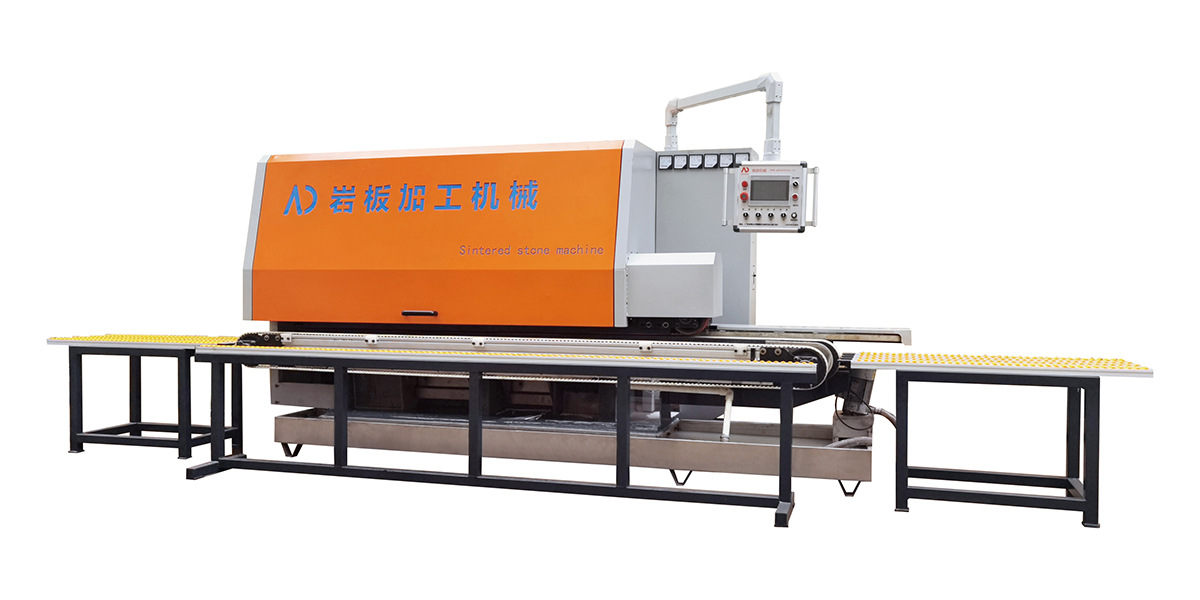

General Side Slant Stone Edge Polishing Machine

- Product Information

The general side slant Stone Edge Polishing Machine is a high-efficiency equipment designed specifically for stone edge processing. It is suitable for edge polishing of various stones such as marble, granite, and artificial stone. This stone edging machine has excellent performance and can provide uniform and smooth edge processing effects for stones. It is an indispensable and important equipment in the stone processing industry. General model of this machine is a market, it is according to different size of stone material thickness, grinding all kinds of flat stone right bottom, right angle 45° bottom chamfer, thicken edge, start groove, the line that play a base, such as the French side molding. In processing and straight edge, cut back, thicken edge, right angle 45° bottom when it can use configuration snail chamfering and fast connection with 1 piece of coarse grinding, fine grinding and polishing process at one time. Easy operation, simple maintenance, mechanical processing instead of traditional stone processing 20 people's workload, and avoid manual processing process defects. As a renowned China stone edging machine exporter, we specialize in delivering precision-engineered stone edging machines that meet international standards.

Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADBM11-60 |

| Voltage | 380V/50Hz |

| Power | 38kw |

| Speed | 0.5-4.5m/r |

| Ston min | 50×50mm |

| Weight | 4200kg |

| Overall size(L×W×H) | 7500×1000×1800mm |

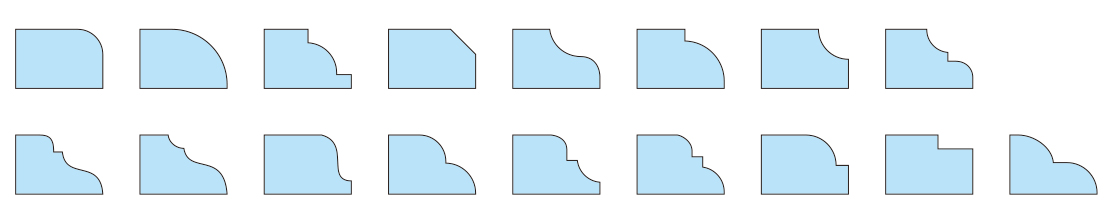

Position of Wheels:

General Side Slant Stone Edge Polishing Machine Features:

1. Efficient polishing: using advanced polishing technology and high-quality abrasives to ensure that the edge of the stone is polished flat and smooth, improving the overall beauty of the stone.

2. Multi-angle adjustment: supports multi-angle adjustment, can handle stone edges of various angles, and meet different processing needs.

3. Intelligent control: equipped with an intelligent control system, simple and convenient operation, can accurately control the polishing process, and improve processing accuracy.

4. Strong durability: made of high-quality materials, with a solid structure and wear resistance, suitable for long-term high-intensity use.

5. Safe and reliable: equipped with multiple safety protection devices to ensure the safety of operators and reduce operating risks.

General Side Slant Stone Edge Polishing Machine Application:

1. Countertop Fabrication: This machine is extensively used in the production of kitchen and bathroom countertops. It can polish granite, marble, and other stone materials to a smooth finish, enhancing the aesthetic appeal and functionality of countertops.

2. Building Construction: For building projects requiring shiny stone components like sill windowsills, door frames or decorative facades, this machine adds touches to polish these stones according to one’s preference. It is versatile for construction purposes because it can handle any kind of stone.

3. Monument and Sculpture Making: Craftsmen and artists use this type of equipment for polishing their sculptures as well as monuments after they have been shaped into forms they would like them so that every single detail about an artistic piece can have a high quality finish.

4. Restoration Works: In restoration projects especially historic buildings or artworks where original material should not be damaged during delicate polishing on the surface of stones, this helps preserve the authenticity and integrity of the work.

5. Tile Manufacturing: The edge polishing machines are very important for tile manufacturers who want to smoothen their tiles’ edges at last since it improves their looks as well as safety by eliminating sharp corners.

General Side Slant Stone Edge Polishing Machine FAQs:

What types of stone can the General Side Slant Stone Edge Polishing Machine handle?

The Stone Edge Machine is versatile and can polish a wide range of stone types, including granite, marble, quartz, and other natural or engineered stones, making it suitable for various applications from countertops to building details.

How does the Stone Edge Machine ensure the safety of its operators?

Safety is a priority with this machine, which includes features such as emergency stop buttons, protective guards around moving parts, and clear safety instructions. It is designed to comply with international safety standards to protect operators from potential hazards.

What maintenance is required to keep the Stone Edge Machine running efficiently?

Regular maintenance includes cleaning the machine after each use, checking and replacing worn-out parts like belts and bearings, and ensuring all electrical components are in good working condition. Periodic professional inspections are also recommended to maintain optimal performance.

How does the Stone Edge Machine handle corner polishing?

The machine is equipped with advanced technology that allows for precise and smooth polishing of corners and curves without chipping or damaging the stone, ensuring a consistent finish across all surfaces.

Can the Stone Edge Machine be customized for specific production needs?

Yes, there are options for customization depending on your specific production requirements. This can include adjustments to the spindle configuration, table size, and even software enhancements to better align with your operational workflow.