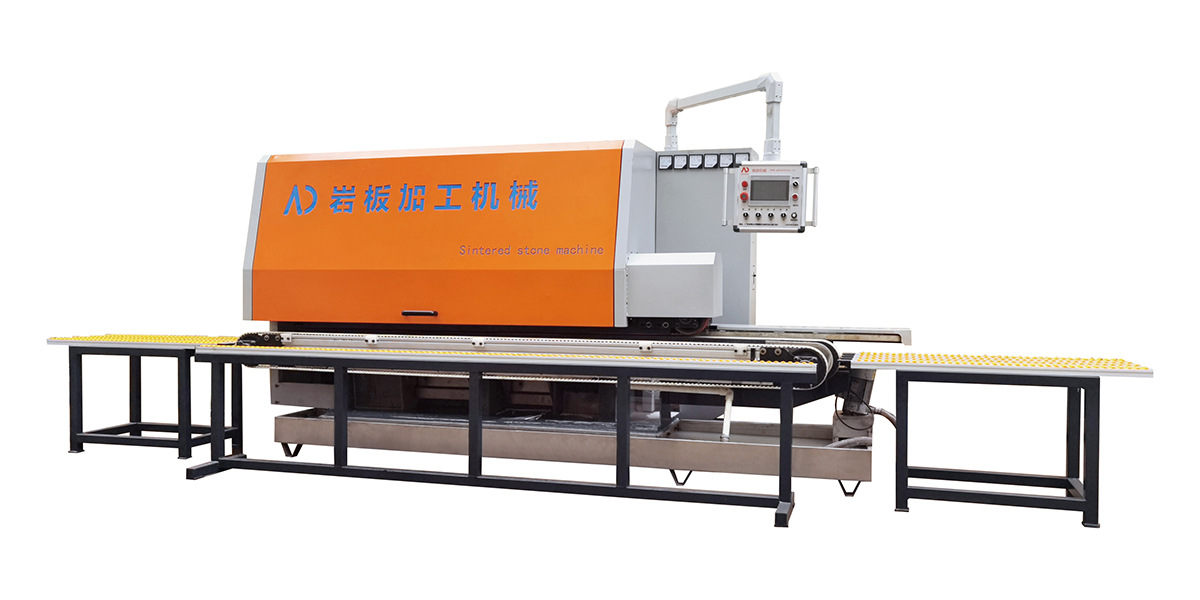

CNC Seamless Horizontal Edging Machine

- Product Information

The CNC Seamless Horizontal Edging Machine is a professional equipment used in industrial manufacturing and construction fields, designed to provide precise and efficient hemming solutions for various materials such as metals, plastics and composites. The high precision and consistency of the seamless horizontal edging machine helps to significantly improve the quality of the final product. Automated operation reduces labor costs and improves production efficiency, thereby reducing overall production costs. It can handle a variety of materials and application scenarios to meet the needs of different customers. The seamless horizontal hemming machine is an indispensable and important equipment in the modern manufacturing and construction industries. With its high efficiency, precision and versatility, it is widely used in various fields that require high-quality edge processing. As a top China seamless horizontal edging machine manufacturer, we are committed to innovation, efficiency, and customer satisfaction.

CNC Seamless Horizontal Edging Machine Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADYB5113-45° |

| Voltage | 380V/50Hz |

| Power | 18kw |

| MitsubishiPLC | FX3GA-41MT |

| Touch screen | 7 Inches |

| Processing width | 25mm-2.4m |

| Feeding speed | 1-4.5m/min |

| Weight of machine | 2600kg |

| Overall size(L×W×H) | 4000×1500×1850mm |

Seamless horizontal glass edging machine is an automated equipment designed specifically for precision processing of glass edges. It efficiently and continuously grinds glass edges through a horizontally arranged grinding wheel set. Its core advantage lies in achieving seamless polishing and high-precision molding of glass edges, suitable for glass deep processing needs in fields such as construction, home appliances, furniture, and automobiles. This equipment adopts advanced numerical control technology, multi-stage grinding process, and intelligent control system, which can process glass substrates with a wide range of thicknesses and diverse size specifications, significantly improving production efficiency and product quality.

characteristic

Multi level grinding and polishing system

Number and layout of grinding wheels: The equipment is equipped with 4-8 sets of independently driven grinding wheels (such as diamond grinding wheels, resin polishing wheels), arranged in the order of rough grinding, fine grinding, and polishing processes, to achieve seamless transition from burrs to mirror surfaces on the glass edges.

Grinding accuracy: The edge roughness can reach Ra 0.01-0.05 μ m, and the straightness error is ≤ 0.1mm/m, meeting the processing requirements of high-precision optical glass or high-end decorative glass.

Grinding efficiency: The single-sided grinding speed can reach 5-15 meters per minute, supporting double-sided synchronous processing, and the production efficiency is increased by more than 30% compared to traditional equipment.

Intelligent Numerical Control System

Control method: Adopting PLC+touch screen control system, supporting preset more than 100 processing parameters, and can quickly switch between different glass specifications (such as thickness 3-25mm, width 50-2500mm).

Automatic compensation function: Built in thickness sensor and pressure feedback system, real-time monitoring of glass thickness changes, automatic adjustment of grinding pressure (0.5-5kg/cm ²), ensuring consistent grinding volume.

Fault diagnosis: The system can display key parameters such as the wear status of the grinding wheel and the flow rate of the coolant in real time. In case of abnormalities, it will automatically shut down and sound an alarm, reducing downtime.

Efficient cooling and environmentally friendly design

Cooling system: A closed-loop water cooling system is adopted, with a coolant flow rate of 20-50L/min and a constant water temperature of 20-25 ℃, effectively reducing the impact of grinding heat on the glass and avoiding crack formation.

Dust recovery: equipped with negative pressure vacuum cleaner, dust recovery rate ≥ 98%, in compliance with ISO 14001 environmental standards, improving workshop air quality.

Low noise operation: The equipment noise is ≤ 75 decibels, and it adopts a soundproof cover and shock-absorbing base design to meet the requirements of industrial noise control.

High compatibility and stability

Glass thickness range: Supports various materials such as flat glass, tempered glass, Low-E glass, etc. with a thickness of 3-25mm.

Edge processing types: can process various shapes such as straight edges, round edges, duckbill edges, oblique edges, etc., and the chamfer angle of the edge can be adjusted from 0-45 °.

Equipment lifespan: Key components (such as spindle and guide rail) are made of imported high-precision materials, with a continuous operating lifespan of ≥ 20000 hours and a 40% reduction in maintenance costs.

Application scenarios

Architectural glass processing

Used for grinding and polishing the edges of high-rise building curtain wall glass and insulated glass, eliminating stress concentration at the edges, and improving the wind pressure resistance and aesthetics of the glass.

Home appliances and furniture glass

Processing refrigerator door glass, shower room glass, coffee table panels, etc., using rounded or duckbill edges to enhance safety and avoid scratching users.

Automotive Glass Manufacturing

Handle the edges of the car's front windshield and side window glass to ensure a perfect fit with the body sealing strip, while meeting the stringent requirements of the automotive industry for edge strength and optical performance.

Photovoltaic and Electronic Glass

Provide ultra precision edge grinding for solar photovoltaic modules and LCD display glass, eliminate micro cracks, and improve photoelectric conversion efficiency or display clarity.

Art and Decorative Glass

Processing the edges of irregular glass and painted glass, and meeting high-end decorative needs through customized grinding of contours (such as wavy edges and lace).