info@gdaddtech.cn

|

+86-18566873215

The glass processing industry has significantly changed throughout the years and Glass Edging Machines have been part of that change. It can be said with great certainty the machines for edging glass will be far better and more advanced in the next decade owing to the emerging technological innovations, a rising appetite for accuracy and efficiency on production tasks and it’s anticipated that these machines will be fully developed.

On-Going Automation and Inclusion of Smart Technologies

Among the most interested expectations on glass edging machines, including those aimed at the production of glass is the tendency to encourage on automation and smart technologies inclusiveness. Sensing the direction for available technology under Industry 4.0, glass processing companies now possess smart machines that connect to one another, extract relevant data and adjust operations where necessary to improve production efficiency. Such machines will integrate sophisticated devices with the help of which Data Analytics processes will visually follow the edges of the glass and assess the edges quality, schedule maintenance requirements and optimize non-working time.

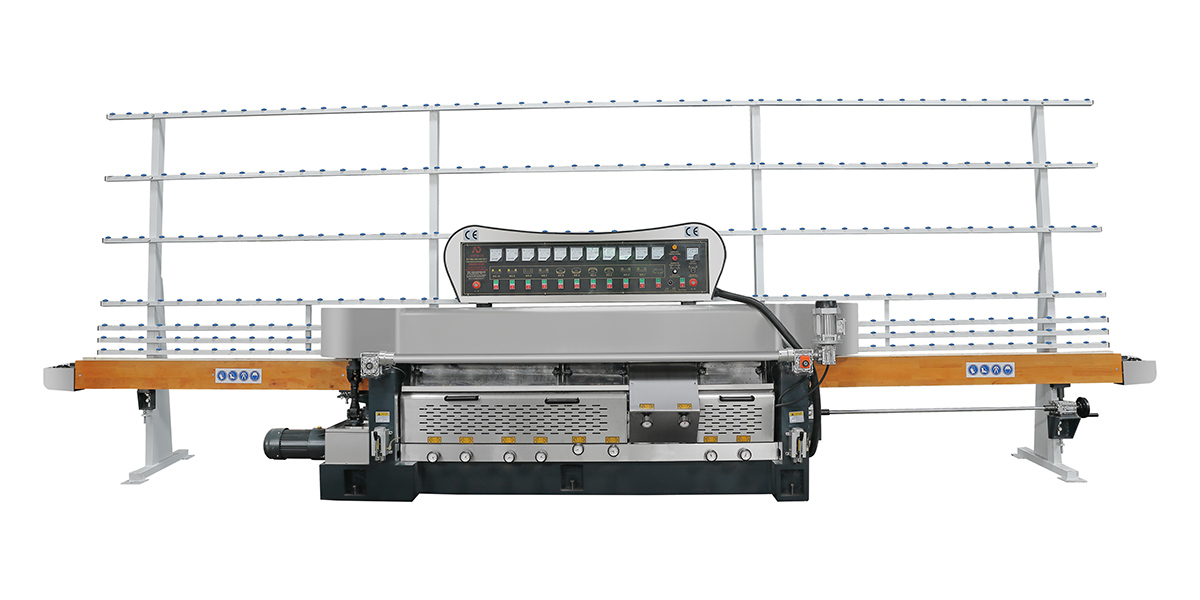

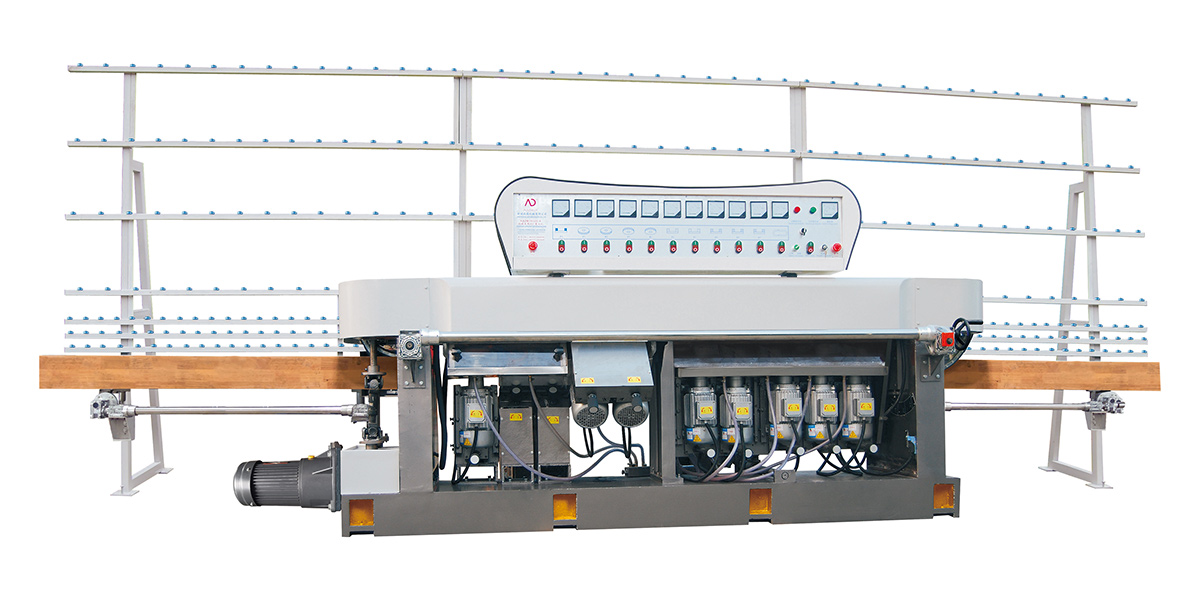

As an example, FOSHAN ADDTECH GLASS MACHINE CO, LTD which has been established in the year 2007 and located in the district of Shunde within the city of Foshan in the province of Guangdong is one of the companies which has embraced this trend. There is a range of high performance glass processing equipment such as straight-line edging machines, beveling machines and round edge machines which are aimed at the future demands. ADDTECH’s sustainability level is so high that deliverables of the machines today will also be efficient enough for the needs of the next 10 years.

Accuracy and Quality Assurance

With consumers constantly demanding a high end in as far as glass is concerned, the manufacturers are turning to accuracy and quality management. People can expect that next glass edging machines will feature a high-tech precision control system which maintains uniformity of edge quality. This will enable producers to manufacture high quality pure glass products without leaving too much waste and at a profit margin.

For instance, ADDTECH’s glass edging machines are equipped with glass processing techniques which have outstanding machining standard and depict the response of the industry to the precision demand. ADDTECH has been able to position itself in the glass making everyone, by continuously improving machining accuracy in addition to operating stringent quality control and inspections in the process of making great products that have a performance rating that is of international standards.”

Energy Efficiency and Sustainability

Smart and increasingly cautious policies about environmental conservation have turned the glass processing industry toward more energy saving sustainability. In the coming years, more energy conserving glass edging machines will be manufactured whilst retaining high productivity. In addition, companies will emphasise the availability of green materials and processes that limit negative impacts to the environment.

ADDTECH's sustainability strategy is well incorporated within their products. They ensure that the machines are energy efficient so as to help the manufacturers lessen their carbon equivalents emission even as they target shooting up production. This is a positive development as it complements the current international movement that calls for more ecologically friendly ways of manufacturing.

Versatility and Customization

In the forthcoming years, the market for the glass edging machines that would perform multi functions and would be easily served by several or individual users will expand. They will be looking for machines that can work with different glass materials of varying thicknesses and give different edge designs for different industrial requirements. This will result to the emergence of cubic machines that are modular and portable, whereby reconfiguration and building better components will be made quite a simple task.

In the case of ADDTECH, this trend is reflected in the product range, which provides for machines with which it is possible to process a wide variety of glass shapes and sizes.Straight line or round edge processing or special edges made as per the customer requirements are all efficiently performed by ADDTECH machines, leaving no stone unturned in satisfying the various needs of the customers.

Remote Monitoring and Predictive Maintenance

As we move ahead, these two are the features that will be found as a norm in glass edging machines in the coming years, thanks to technology that keeps improving. With these technologies, manufacturers will be able to view how their machines have been operating, and whenever a problem arises, they can be aware of it, and even when there is no problem present, they can be informed of the need fo

r maintenance before any problem occurs. This method is likely to minimize idleness and enhance how long the machines will last.

Given ADDTECH’s commitment to quality and product innovation, their machines are expected to incorporate these advanced features probably in the near future. ADDTECH has incorporated ways to identify trends in the industry and ensure their clients are reaping from advanced technologies.

The future of technologies concerned with the glass edging machines in particular and glass processing in general stands to improve indeed with new improvements coming in as regards automation, precision, energy, multi-appliction and off-site supervision. FOSHAN ADDTECH GLASS MACHINE CO., LTD is one of the key players in this industry and naturally follows the market trends. On focusing and persistent, ADDTECH shall be in the near future a strong player in the glass edging technologies market.