info@gdaddtech.cn

|

+86-18566873215

Choosing the right Glass Edging Machine is critical not only to productivity maximization but also quality product output and cost control in glass processing activities. Be it in case of limited production or mass production, the right device has a huge impact. That is how to make a smart choice when it comes to glass edging machines to be fixed on the production line. 1. Know what you are producing The very first step towards the selection of a good glass edging machine is to quantify the requirements to be met. Take into consideration how much glass you need to treat, what type of edges do you require (straight, inclined, or round), and for what purpose the glass products will be used. For instance, if you are making glasses possessing very high sense of furniture depth and do curved shaping of glasses the detail and edge quality would be the key feature.

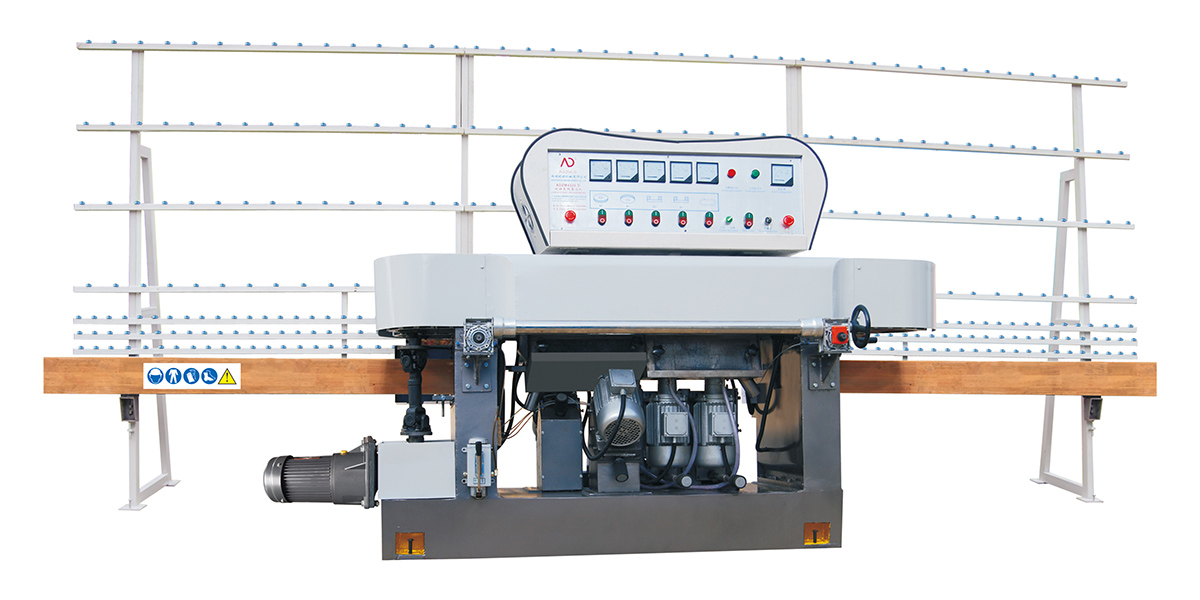

FOSHAN ADDTECH GLASS MACHINE CO., LTD was established in 2007, and it is engaged in development and manufacture of glass processing machinery . Based in Shunde District of Foshan City, Guangdong Province, ADDTECH manufactures and sells straight-line edging machines, beveiling machines, round edge machines among other products. Each available machine covers certain production need thereby enabling all operators to get the most appropriate machine for their needs.

Noticeable Features

There are a few noticeable features that each and every glass edging machine that you should consider when purchasing:

Precision and Accuracy: Additionally, the level of edge finishing is likely to vary with the machine. For example, such machines offered by ADDTECH are also particularly known for their machining accuracy which is a need in most applications where clean and smooth edges are required.

Durability and Build Quality: Make sure that the construction of the machine is sturdy enough in case of a production environment where there are repetitive activities. ADDTECH’s equipment is also well constructed using appropriate materials which will guarantee performance and durability for many years.

Ease of Use: Without ease of use of controls and maintenance, it is difficult to achieve productivity and decrease the downtimes. ADDTECH’s machines have easy to use controls and good maintenance design which abridges the training of your operators.

Manufacturing Process and Quality Assurance

No matter the cost, it is imperative to find out how the machine you intend to buy is manufactured and what quality assurance measures have been put in place. For example, ADDTECH is a company that brandish’s the preeminent brand images and strives to develop high quality. The company has over the years improved machining performance and performs major inspection so that every machine produced is in good standard within the industry’s expectations.

Application Scenarios

Different glass edging machines are useful for different applications. For instance:

Straight Line Edging Machines: These machines are able to manufacture clean and straight edges on glass panels which are generally used on windows, mirrors and furniture.

beveling machines: They are mostly used for the purpose of dressing the edges of specific glass items, mostly for the decorative glasses and mirrors.

Round Edge Machines: They are ideal for the edges of safety glasses utilized in automotive as well as architectural purposes.

ADDTECH provides all the required machines, making sure that there is a machine that can meet all the glass processing needs.

After-Sales support and Service

Last but not least, do a bit of analysis on the after sales support and service of the manufacturer. Having good technical assistance and spare parts in stock are very important as they can greatly improve the performance of a production line. ADDTECH offers outstanding assistance to its clients so that all business operations run as expected.

In order to settle on a glass edging machine that satisfactorily meets production needs, and machine functionalities, it is essential to evaluate the finish of a product as well as the level of support by the manufacturer. It is evident that FOSHAN ADDTECH GLASS MACHINE CO., LTD is one of the top manufacturers that offers an extensive colossal range of glass processing equipment for any and every industry, including the glass industry. There is no doubt that when you purchase one of ADDTECH’s machines, you are purchasing precision, strength, and more importantly, productivity of your production line for the long haul.

There is a contact possibility to FOSHAN ADDTECH GLASS MACHINE CO., LTD for further details:

Mobile: +86-18566873215

Address: NO.17 Junma Road, Magang Industrial Zone, Ronggui Street, Shunde District, Foshan City, Guangdong Province, China

Website: www.gdaddtech.cn

E-mail: info@gdaddtech.cn