Semi-Automatic Irregular Glass Grinding Machine

- Product Information

Irregular Glass Grinding Machine is an indispensable equipment in the field of glass processing. It is mainly used for edge grinding of glass of various shapes. It can meet the processing needs of various special shapes of glass. Whether it is round, oval or other irregular shapes of flat glass, the equipment can achieve fine edge processing. In the process of glass processing, edge processing is crucial to the overall quality and aesthetics of glass. The irregular glass edge grinding machine ensures the smoothness and flatness of the glass edge through precise grinding technology, providing a solid foundation for the subsequent application of glass products.

Irregular Glass Grinding Machine Technical Specifications:

| Item | Technical Specifications |

| Model Number | AD1321 |

| Voltage | 380V/50Hz |

| Power | 3kw |

| Movable diameter | 100×2000mm |

| Glass thickness | 3-25mm |

| Oblique angle | 0-20° |

| Speed of the satelite disc | 0.5-2.5m/min |

| Weight of machine | 1000kg |

| Overall size | 1000×1600×1200mm |

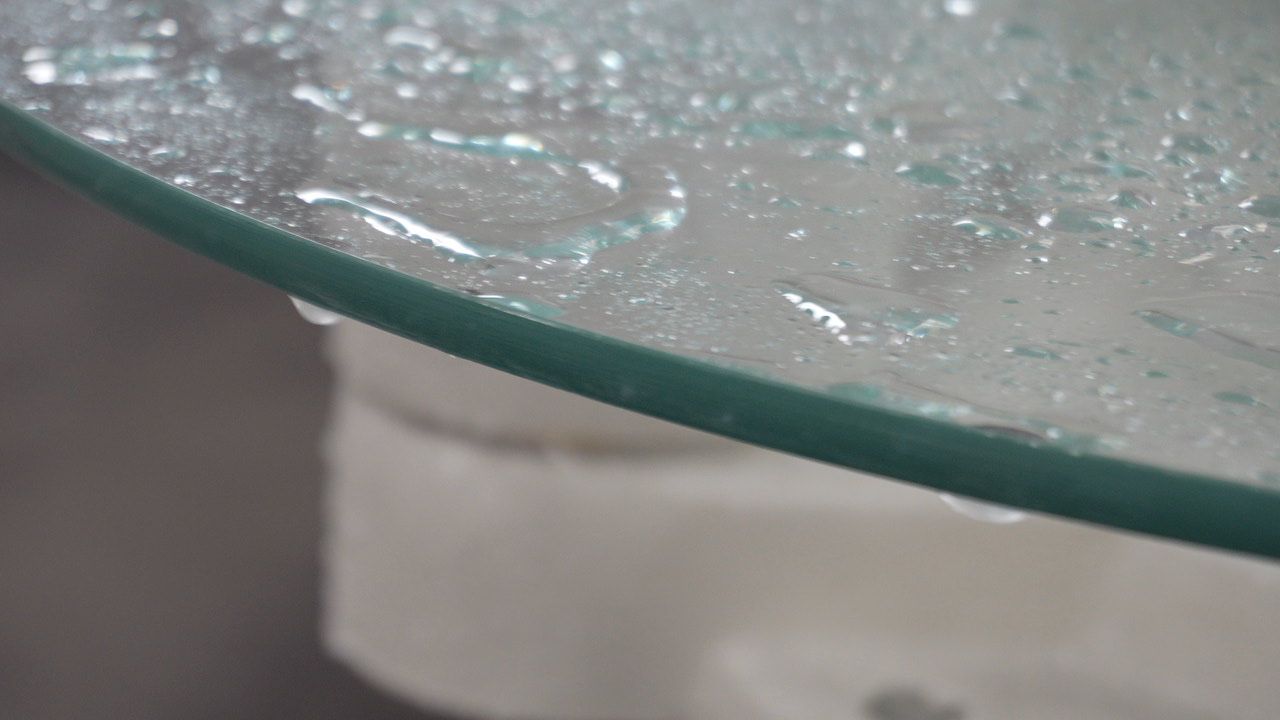

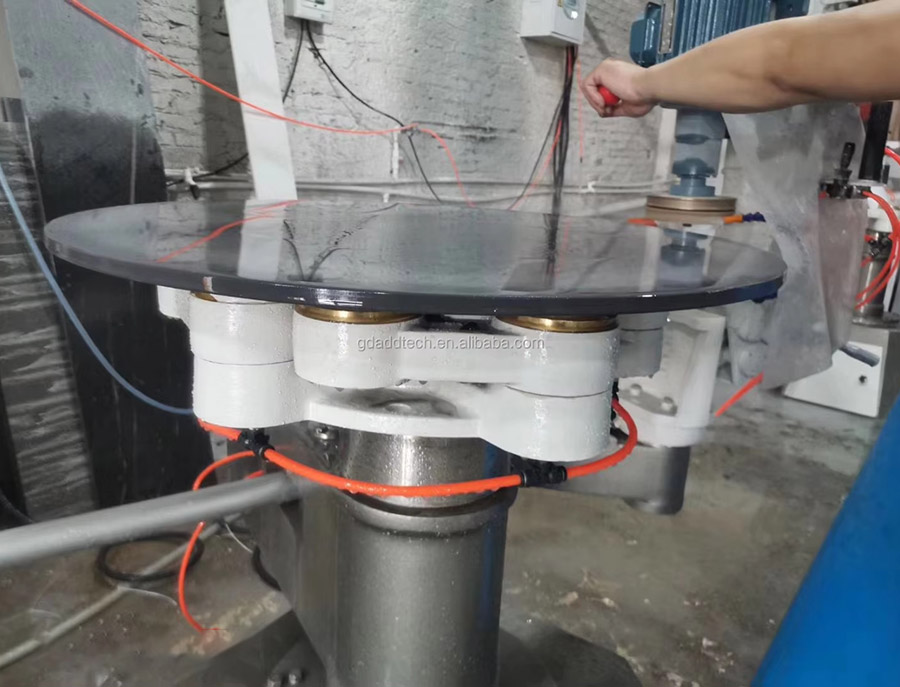

Irregular Glass Grinding Machine Detailed Images:

Irregular Glass Grinding Machine Features:

1. Precision grinding:

The AD1321 Semi-Automatic Irregular Glass Grinding Machine adopts advanced grinding technology and can grind the glass edge with high precision. Its grinding accuracy can reach micron level, ensuring the flatness and smoothness of the glass edge. Whether it is a complex curved edge or a sharp corner, it can achieve uniform and consistent grinding effect, meeting the strict requirements of different customers for the quality of glass edges.

2. Flexible drive:

The Irregular Glass Grinding Machine is equipped with an independent five-star turntable rotation system. The rotation speed of the turntable can be adjusted according to the processing requirements, ranging from 0.5 - 2.5m/min. This flexible drive mode enables the equipment to adapt to glass processing of different shapes and sizes. Whether it is large or small glass, it can achieve efficient grinding processing, greatly improving production efficiency.

3. Vacuum adsorption:

The glass is fixed on the workbench of the Semi-Automatic Irregular Glass Grinding Machine by a vacuum suction cup. This adsorption method can ensure the stability of the glass during processing. The suction force of the vacuum suction cup is evenly distributed, which will not damage the glass. At the same time, it can also ensure the accurate position of the glass during the grinding process, avoid processing errors caused by glass movement, and improve the reliability and consistency of processing.

4. Multi-purpose grinding head:

Irregular Glass Grinding Machine is equipped with a variety of grinding heads, which can be replaced according to different grinding needs. When grinding round edges, three grinding heads can be installed for rough grinding, fine grinding and polishing respectively; when grinding bevel edges, a bowl-shaped grinding wheel is used, and the bevel angle is adjusted by tilting the grinding head. This multi-purpose grinding head design enables the equipment to be used for multiple purposes, meet the needs of various edge grinding processes, and reduce the purchase cost of the equipment.

5. Stable performance:

Semi-Automatic Irregular Glass Grinding Machine is made of high-quality steel as a whole, with a stable structure, a weight of 1000kg, and a size of 1000×1600×1200mm. This sturdy structural design allows the equipment to remain stable during long-term operation, reduce the impact of vibration on processing accuracy, extend the service life of the equipment, and ensure that the equipment can operate stably in various harsh working environments.

6. High efficiency and energy saving:

The voltage of Semi-Automatic Irregular Glass Grinding Machine is 380V/150Hz and the power is 3kw. It can achieve energy-saving operation while ensuring efficient processing. Its efficient motor drive system and optimized grinding process enable the equipment to minimize energy consumption and reduce production costs during the processing process, which is in line with the energy-saving concept of modern industry.

7. Easy operation:

The operating interface of Semi-Automatic Irregular Glass Grinding Machine is simple and easy to use. Operators can master the operation method of the equipment after simple training. The semi-automatic design of the equipment allows automatic grinding processing to be achieved with simple settings and adjustments during operation, which greatly reduces the difficulty of operation and improves production efficiency.

8. Safe and reliable: Semi-Automatic Irregular Glass Grinding Machine fully considers the safety of operators during the design process, and sets safety protection devices at key locations, such as emergency stop buttons, protective covers, etc. These safety devices can effectively prevent operators from being accidentally injured during the processing process, ensure the safe and reliable operation of the equipment, and provide operators with a safe working environment.

Irregular Glass Grinding Machine Application:

1. Architectural glass processing:

In the field of architecture, Semi-Automatic Irregular Glass Grinding Machine is widely used in the processing of various architectural glasses. For example, for the curtain wall glass of some large buildings, its shape is often irregular, and it is necessary to use this equipment for precise edge grinding to ensure that the glass can perfectly fit the building structure. At the same time, for the decorative glass inside the building, such as stair railing glass, partition glass, etc., it is also necessary to use the edge grinding machine to process smooth edges to improve the safety and aesthetics of the glass.

2. Furniture glass manufacturing:

In the furniture manufacturing industry, glass furniture is increasingly favored by consumers. Semi-Automatic Irregular Glass Grinding Machine can be used to process various furniture glasses, such as coffee table glass, dining table glass, etc. These glasses usually need to be processed with rounded edges to avoid scratching the user. Through the edge grinding treatment of this equipment, the edges of the furniture glass can be made smooth and burr-free, improving the overall quality and safety of the furniture.

3. Automobile glass processing:

The shape of automobile glass is complex, especially the front windshield and side window glass of the car, which require precise edge grinding. Irregular Glass Grinding Machine can meet the processing needs of automotive glass and ensure the smoothness and flatness of the glass edge. This is crucial for the sealing, safety and aesthetics of the car. The automotive glass processed by this equipment can be better combined with the car body and improve the overall performance of the car.

4. Art glass production:

Art glass has attracted much attention in the art field for its unique beauty and decorative effects. Irregular Glass Grinding Machine can be used to process various art glasses, such as colored glass, carved glass, etc. These glasses often need to be processed into complex edge shapes to meet the requirements of artistic design. Through the fine edge grinding of this equipment, the edge of the art glass can be made more refined and show a unique artistic charm.

5. Electronic glass processing:

With the continuous development of electronic technology, the application of electronic glass is becoming more and more extensive. For example, mobile phone screen glass, computer monitor glass, etc. all need fine edge grinding. Irregular Glass Grinding Machine can meet the processing accuracy requirements of electronic glass and ensure the smoothness and flatness of the glass edge. This is of great significance to the display effect and service life of electronic products.

6. Other glass products processing:

In addition to the above application areas, Semi-Automatic Irregular Glass Grinding Machine can also be used to process various other glass products, such as glass crafts, glass lamps, etc. These glass products have different shapes and sizes, and need to be processed by this equipment for personalized edge grinding to meet different design and use requirements. Through the processing of this equipment, the edges of these glass products can be made more beautiful and the added value of the products can be increased.

Irregular Glass Grinding Machine Maintenance:

1. Daily cleaning:

The Semi-Automatic Irregular Glass Grinding Machine should be cleaned in time after use to remove glass debris and dust from the workbench, grinding head and other parts. Use a soft cloth dipped in a small amount of detergent to gently wipe the surface of the equipment. Avoid using hard objects or corrosive detergents to avoid damaging the surface of the equipment. Regular cleaning of the equipment can maintain the good appearance of the equipment, and it also helps to reduce the impact of dust on the operation of the equipment and extend the service life of the equipment.

2. Maintenance of the vacuum system:

The vacuum system is an important part of the Irregular Glass Grinding Machine, and its performance directly affects the adsorption effect of the glass. Check the working status of the vacuum pump regularly to ensure the normal operation of the vacuum pump. At the same time, clean the vacuum pipes and suction cups regularly to prevent dust and debris from clogging the pipes and affecting the vacuum system's exhaust efficiency. It is recommended to conduct a comprehensive inspection and cleaning of the vacuum system once a week to ensure that it is in good working condition.

3. Inspection and replacement of grinding heads:

The grinding head is the core component of the Irregular Glass Grinding Machine, and its wear will directly affect the quality of edge grinding. Regularly check the wear of the grinding head. If the grinding head is severely worn or cracked, replace it with a new one in time. When replacing the grinding head, strictly follow the requirements of the equipment manual to ensure that the grinding head is firmly installed. At the same time, choose the appropriate grinding head according to different processing requirements to ensure the grinding effect.

4. Lubrication and inspection:

The moving parts of the Semi-Automatic Irregular Glass Grinding Machine need to be lubricated regularly to reduce friction between parts and extend the service life of the equipment. According to the requirements of the equipment manual, add an appropriate amount of lubricating oil to the lubrication points regularly. At the same time, regularly check whether the fasteners of the equipment are loose. If loose, tighten them in time. It is recommended to lubricate and inspect the equipment once a month to ensure the normal operation of the equipment.

5. Electrical system maintenance:

The electrical system is the power source of the Semi-Automatic Irregular Glass Grinding Machine, and its normal operation is crucial to the stable operation of the equipment. Regularly check whether the electrical circuit is firmly connected and whether there is any damage or aging. At the same time, regularly check the running status of the motor. If the motor is found to be running abnormally, it should be repaired or replaced in time. It is recommended to conduct a comprehensive inspection and maintenance of the electrical system every quarter to ensure that it is in good working condition.

6. Regular calibration:

In order to ensure the processing accuracy of the equipment, the Irregular Glass Grinding Machine needs to be calibrated regularly. The calibration content includes the position accuracy of the grinding head, the rotation accuracy of the turntable, etc. Professional calibration tools and instruments can be used for calibration to ensure that the various parameters of the equipment meet the processing requirements. It is recommended to conduct a comprehensive calibration of the equipment every six months to ensure the processing accuracy and stability of the equipment.