Horizontal 2500mm Glass Washing Machine

- Product Information

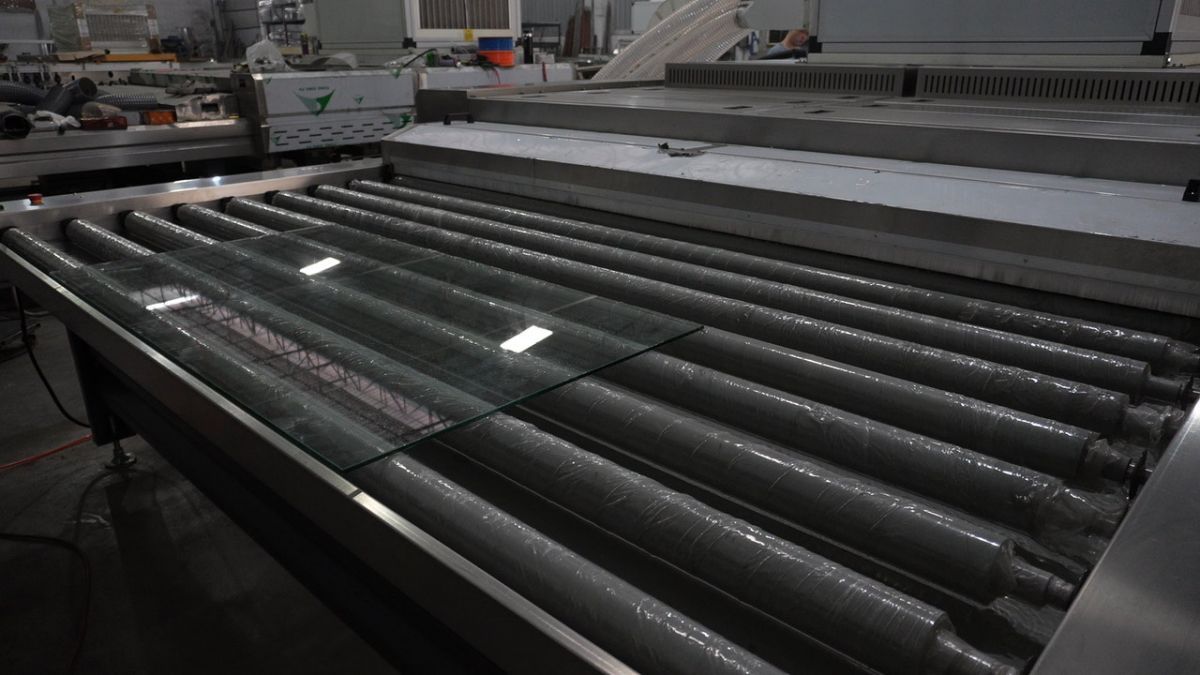

The horizontal 2500mm Glass Washing Machine is a state-of-the-art equipment designed for efficient and thorough cleaning of glass surfaces. Suitable for both flat and shaped glass, this machine is essential for industries such as glass manufacturing, construction, automotive, and more. ADQX2500A glass washing machine, washing glass thickness from 3~19mm, adopted auto-cleaning and a hot air drying system. Air knife supply air powerfully, suitable for coating film, mirror clean and washing before toughened. As a leading China 2500mm glass washing machine manufacturer, we pride ourselves on our innovative technology, skilled workforce, and rigorous quality control measures.

Horizontal 2500mm Glass Washing Machine Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADOX2500A |

| Voltage | 380V/50Hz |

| Power | 35kw |

| Maximum processing width | 2500×3000mm |

| Minimum processing width | 400×400mm |

| Glass thickness | 3-25mm |

| Feeding speed | 0.5-10m/min |

| Weight of machine | 4000kg |

| Overall size | 6500×2300×3300mm |

Horizontal 2500mm Glass Washing Machine Packaging & Shipping:

The 2500mm glass cleaning machine is a professional cleaning equipment designed specifically for processing large glass with a width of up to 2500mm. It plays an important role in various glass application fields such as construction, automotive, photovoltaics, and home appliances. It integrates advanced technologies such as high-pressure spraying, brush cleaning, and air knife drying, which can efficiently remove various impurities on the surface of glass, ensuring that the glass meets extremely high cleanliness standards and meets strict requirements for subsequent processing or use.

characteristic

Ultra wide cleaning capability

Cleaning width: Supports glass cleaning with a maximum width of 2500mm, covering the processing needs of large-sized glass such as large building curtain wall glass and solar photovoltaic modules.

Glass thickness compatibility: It can clean glass with a thickness range of 3-25mm and adapt to different specifications of glass substrates.

Cleaning efficiency: The cleaning speed can reach 5-35 meters per minute, and can be flexibly adjusted according to the degree of glass dirt to ensure efficient production.

Multi level cleaning system

High pressure spraying technology: equipped with multiple sets of high-pressure nozzles, spraying pressure of 0.3-0.6MPa, covering both sides of the glass, quickly dissolving oil and dust.

Brush deep cleaning: Using high-density nylon brushes with a speed of 100-300 revolutions per minute, it can effectively remove stubborn stains and particles.

Pure water spray rinsing: Use RO pure water for final rinsing to ensure that there are no water stains or ion residues on the glass surface, and the cleanliness meets ISO 16232 standard.

Efficient drying system

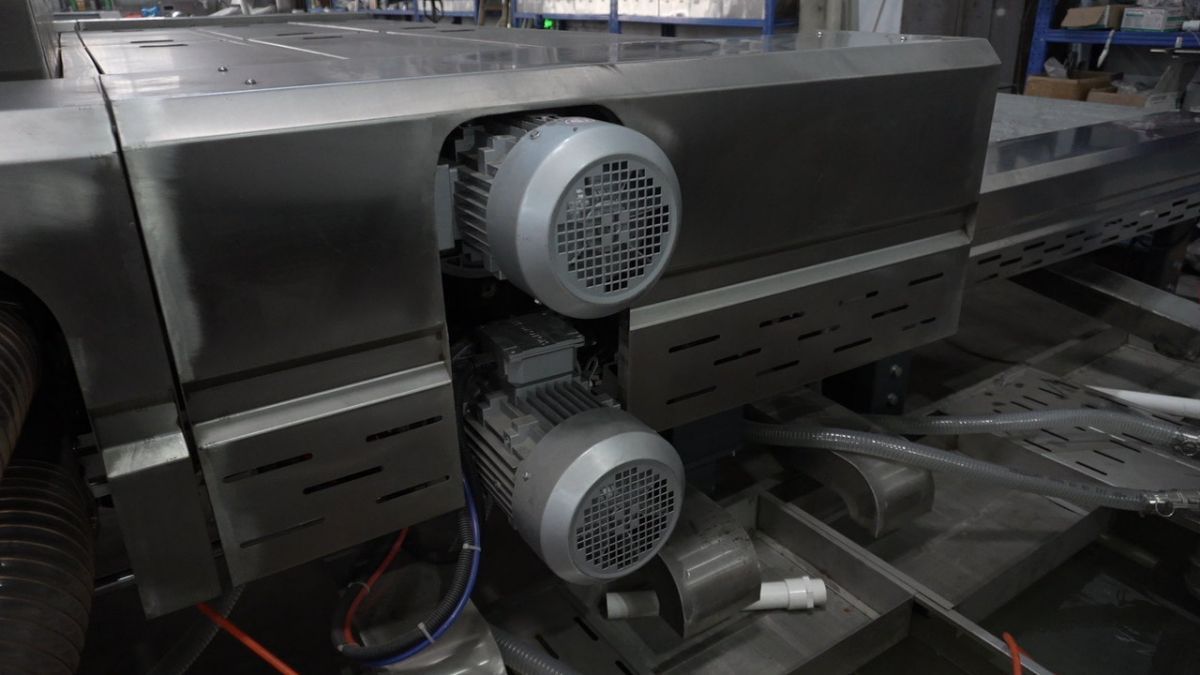

Wind knife drying technology: equipped with high-power wind knives, wind speed of 100-150m/s, wind temperature adjustable to 40-60 ℃, quickly blow dry the moisture on the glass surface.

Drying time: The drying time for single-sided glass is only 1-2 seconds, avoiding the formation of water marks and improving the yield rate.

Air filtration: Dry air undergoes three-stage filtration to ensure a dust-free environment and prevent secondary pollution.

Intelligent control system

PLC+touch screen operation: Adopting Siemens PLC control system, paired with 10 inch color touch screen, supporting multilingual interface and one click operation.

Automatic detection function: Built in glass thickness sensor and position detection device, can automatically adjust cleaning parameters to adapt to different glass specifications.

Fault diagnosis system: Real time monitoring of equipment operation status, automatic alarm and display of fault codes in case of abnormalities, facilitating quick maintenance.

Energy saving and environmentally friendly design

Water circulation system: The cleaning water is filtered and reused, with a water recovery rate of over 90%, reducing water resource consumption.

Low energy consumption operation: The total power is controlled within 30-50kW, using variable frequency drive technology to automatically adjust energy consumption according to the load.

Low noise design: The operating noise of the equipment is below 70 decibels, which meets industrial environmental standards and improves the working environment in the workshop.

Application scenarios

Deep processing of architectural glass

Used for cleaning large building curtain wall glass, Low-E insulated glass, etc., removing oil stains and glass powder after cutting and grinding, and providing clean substrates for subsequent processes such as tempering and laminating.

Photovoltaic glass manufacturing

In the production of solar photovoltaic modules, cleaning the surface of ultra white embossed glass ensures high transmittance and improves the photoelectric conversion efficiency of photovoltaic cells.

Automobile glass production

Clean the front windshield, side window glass, etc. to remove printing ink residue and fingerprints, ensuring the transparency and safety of the glass.

Home appliance glass panel processing

Used for cleaning glass panels of household appliances such as refrigerators and washing machines, removing stains during processing, and improving product appearance quality.

Furniture glass and decorative glass

Clean decorative glass such as art glass and painted glass to ensure a flawless surface and meet high-end customization needs.

Maintenance and upkeep

Daily cleaning and inspection

After each use, clean the glass debris and stains on the surface of the equipment, and check whether the nozzle and brush are blocked or worn.

Regularly check the lubrication of the transmission chain and bearings, replenish lubricating oil in a timely manner, and prevent excessive wear.

Water quality management and maintenance

Replace the cleaning water in the circulating water tank once a week to avoid impurities accumulating and affecting the cleaning effect.

Clean the filter element and reverse osmosis membrane of the RO pure water system every month to ensure that the water quality meets the standard.

Electrical system maintenance

Check the wiring of electrical components for looseness every month to ensure the safe operation of the equipment.

Perform software upgrades on the PLC control system every quarter to optimize equipment performance.

Wind knife and drying system maintenance

Clean the dust and debris inside the wind blade every two weeks to ensure stable wind speed.

Regularly check the operation status of the heating tube to ensure uniform air temperature and avoid local overheating.

Professional maintenance and calibration

Invite professional technicians to conduct comprehensive equipment maintenance every six months, including mechanical accuracy calibration, sensor sensitivity testing, etc.

Perform annual major maintenance on the equipment, replace vulnerable parts such as brushes and seals, and extend the service life of the equipment.