High Speed 1200mm Glass Washing Machine

- Product Information

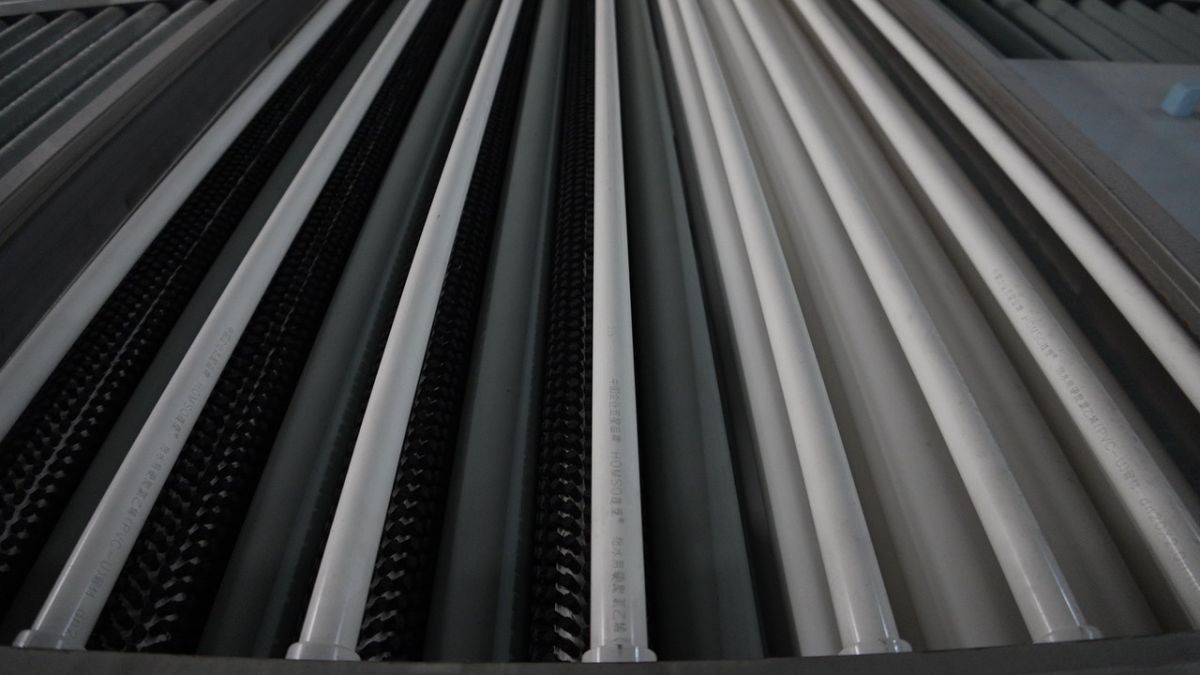

High speed 1200mm glass washing machine is a professional equipment designed for cleaning and drying glass sheets. It is suitable for various glass processing plants, including architectural glass, automotive glass, home appliance glass and other industries. ADQX1200A 1200mm glass washing machine, washing glass by four brush rollers, sop up by three sponge rollers, plus with a hot air drying system. Working speed can be adjusted by continuously variable mechanism transmission, suit for washing different size and thickness glass. Stable and reliable. As a premier China 1200mm glass washing machine manufacturer, we utilize state-of-the-art equipment and adhere to stringent quality control standards to ensure our products meet international benchmarks.

Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADQX1200A |

| Voltage | 380V/50Hz |

| Power | 9kw |

| Maximum processing width | 1200×3000mm |

| Minimum processing width | 100×100mm |

| Glass thickness | 2-19mm |

| Feeding speed | 1.5-6m/min |

| Weight of machine | 900kg |

| Overall size | 3000×1020×1500mm |

The 1200mm glass cleaning machine is a professional equipment designed specifically for cleaning glass with a width not exceeding 1200mm, widely used in the glass processing industry. It removes impurities such as stains, dust, and oil stains from the glass surface through a series of efficient cleaning and drying steps, ensuring that the cleanliness of the glass surface meets the requirements for subsequent processing or use. This equipment integrates advanced technologies such as mechanical transmission, spray cleaning, and air knife drying, and has the characteristics of high cleaning efficiency, good cleaning effect, easy operation, and high degree of automation. It is an indispensable and important equipment for glass deep processing enterprises.

characteristic

Efficient cleaning capability:

Cleaning width: Supports glass cleaning with a maximum width of 1200mm, meeting most glass processing needs.

Cleaning speed: Depending on the thickness and degree of dirt of the glass, the cleaning speed can be adjusted within the range of 5-30 meters per minute to ensure efficient production.

Spray system: Multiple sets of high-pressure nozzles are used, with a spray pressure of 0.3-0.5MPa, ensuring that the cleaning solution evenly covers the glass surface and effectively removes stubborn stains.

Accurate drying system:

Wind blade design: Equipped with an efficient wind blade, the wind speed can reach 80-120m/s, quickly drying the moisture on the glass surface and avoiding water stains.

Drying efficiency: The drying time is short, usually within 1-3 seconds to complete the drying of single-sided glass, improving overall production efficiency.

Intelligent control system:

PLC control: It adopts programmable logic controller (PLC) to achieve automation control, and can preset multiple cleaning programs to adapt to different glass types and cleaning needs.

Touch screen operation: Equipped with a color touch screen, the operation interface is intuitive and easy to understand, making it convenient for operators to set parameters and monitor device status.

Energy saving and environmentally friendly design:

Water circulation system: Clean water is filtered and recycled to reduce water waste and wastewater discharge.

Low noise operation: The equipment operates with a noise level below 75 decibels, which meets environmental requirements and improves the working environment.

Durable and sturdy structure:

Material selection: The main components are made of stainless steel and high-quality alloy materials, which are corrosion-resistant, wear-resistant, and extend the service life of the equipment.

Modular design: easy to maintain and upgrade, reducing maintenance costs and time.

Application scenarios

Architectural glass processing: On the production line of architectural glass, a 1200mm glass cleaning machine is used to clean the glass after cutting and grinding, providing clean glass substrates for subsequent processes such as tempering and coating.

Automotive glass manufacturing: Automotive glass requires extremely high cleanliness, and this equipment can effectively remove oil stains and fingerprints on the surface of the glass, ensuring the quality and safety of automotive glass.

Production of glass panels for household appliances: In the production of glass panels for refrigerators, washing machines, and other household appliances, cleaning machines ensure that the surface of the panel is flawless and improve the appearance quality of the product.

Solar photovoltaic glass: used for cleaning photovoltaic glass, removing surface impurities, improving photoelectric conversion efficiency, and ensuring the performance of solar panels.

Maintenance and upkeep

Daily cleaning:

After each use, the glass shards and stains on the surface of the equipment should be cleaned to keep it clean.

Regularly check whether the nozzle is blocked, and if there is any blockage, it should be cleaned in a timely manner to ensure the spraying effect.

Lubrication and maintenance:

Regularly add lubricating oil to the transmission components of the equipment, such as chains and bearings, to reduce wear and extend their service life.

Check the operation of the motor and gearbox to ensure their normal functioning.

Water quality management:

Regularly replace the cleaning water to avoid excessive impurities in the water affecting the cleaning effect.

The water tank should be cleaned regularly to prevent bacterial growth and scale accumulation.

Electrical system inspection:

Regularly check whether the connections of electrical components are loose to ensure the safety of the electrical system.

Check the working status of sensors and limit switches to ensure accurate and reliable automation control of the equipment.

Professional maintenance:

Regularly invite professional technicians to conduct comprehensive inspections and maintenance of equipment, promptly identify and solve potential problems.

Update and optimize the software system of the device to improve its performance and stability.