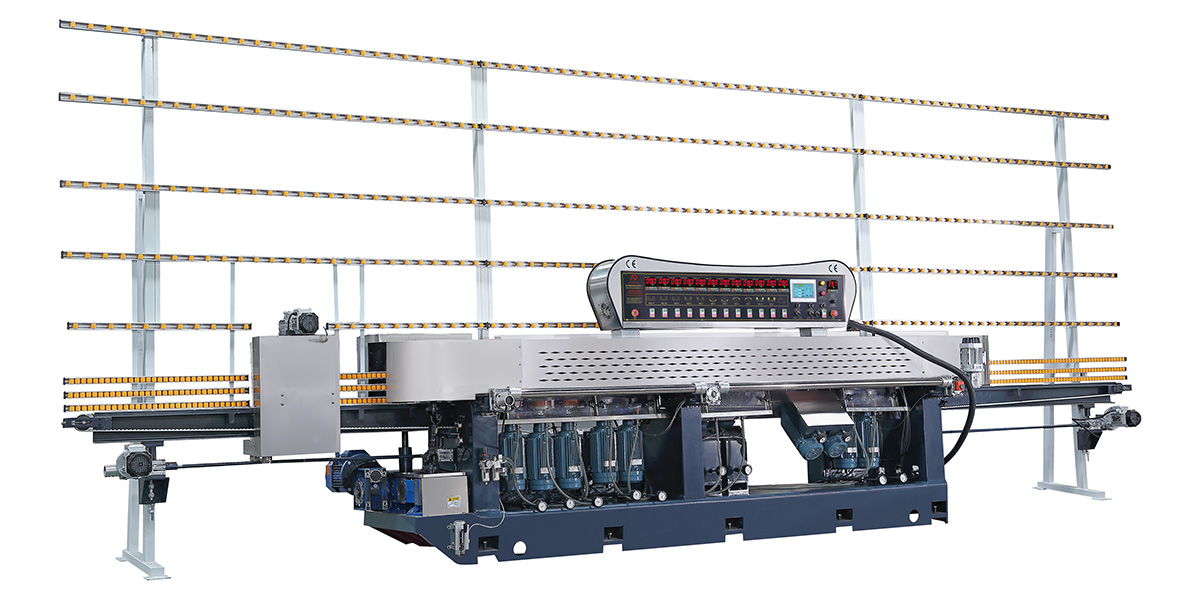

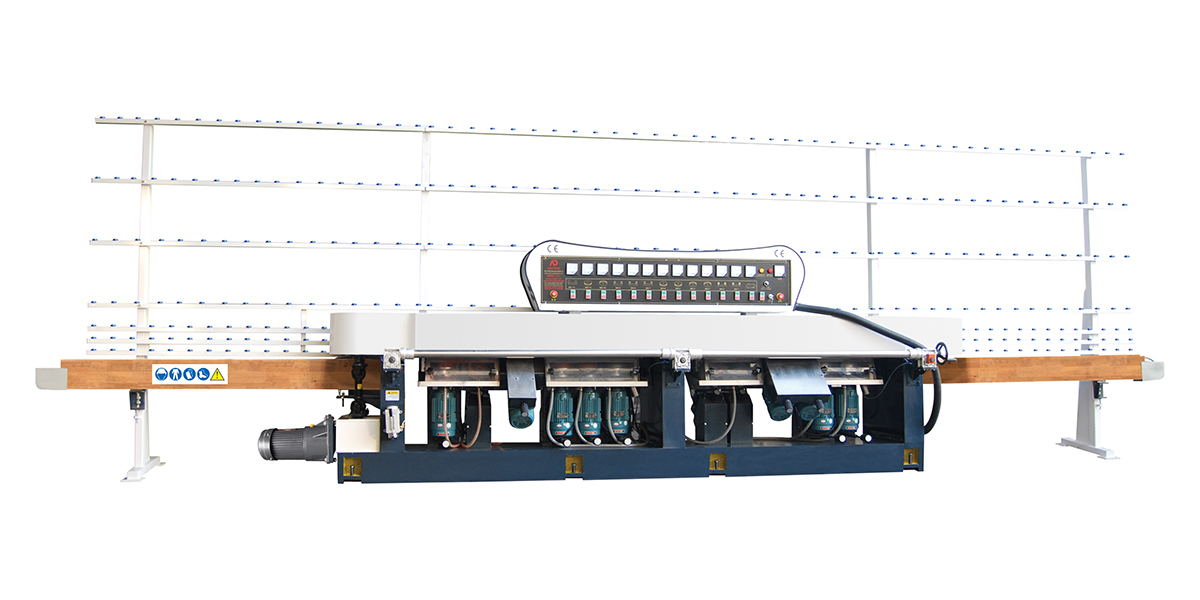

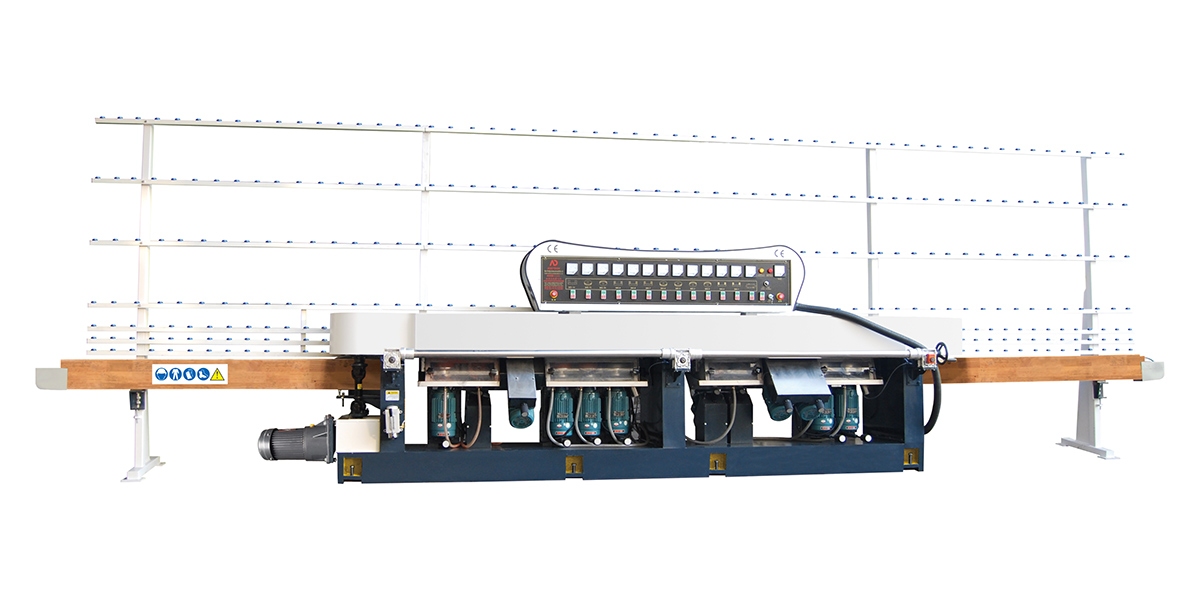

12 Motors Glass Straight Line Edging Machine

- Product Information

As a star product of ADDTECH, 12 Motors Glass Straight Line Edging Machine is a powerful tool in the field of high-precision glass processing. With its excellent performance and advanced technology, this equipment has brought a qualitative leap to the glass processing industry. It embodies the wisdom and hard work of the ADDTECH R&D team. After countless tests and improvements, it has become a mature and stable product. In many aspects of glass processing, 12 Motors Glass Straight Line Edging Machine plays an indispensable role and provides reliable guarantee for the fine processing of glass products. Its exquisite craftsmanship and high-end technical configuration make it stand out from many similar equipment and become an ideal choice in the eyes of major glass processing companies. It can not only efficiently complete the straight line edging of glass, but also has many practical functions and characteristics, which can greatly improve the efficiency and quality of glass processing, and inject strong impetus into the upgrading and development of the glass processing industry.

12 Motors Glass Straight Line Edging Machine Main Configuration:

* Manual control thickness / Eletric control with display

* JINGLONG / CDQC /ABB motors can choose

* All main part cast iron and annealing treating

* All face of main part and slider were grinding by grinding machine

12 Motors Glass Straight Line Edging Machine Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADZM12325 |

| Voltage | 380V/50Hz |

| Power | 27kw |

| Glass thickness | 3-25mm |

| Feeding speed | 0.5-7m/min |

| Min size | 80×80mm |

| Weight of machine | 3500kg |

| Overall size | 8000×2500×1000mm |

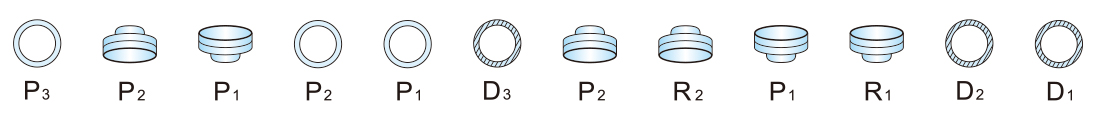

12 Motors Glass Straight Line Edging Machine Position of Wheels:

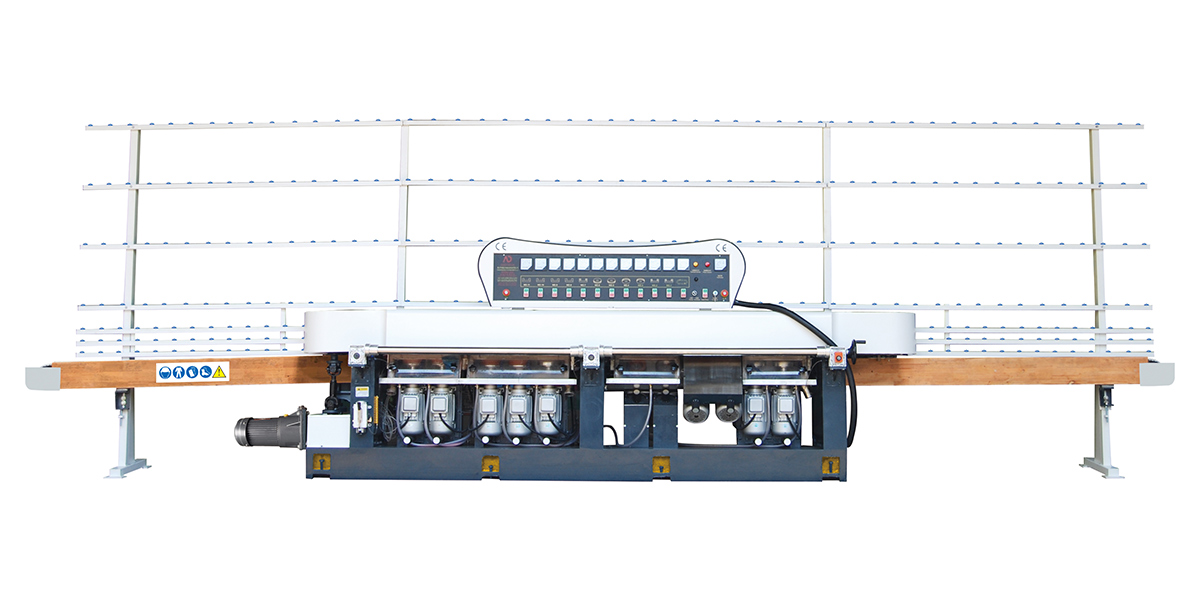

12 Motors Glass Straight Line Edging Machine Features:

Efficient power:

12 Motors Glass Straight Line Edging Machine is equipped with 12 powerful motors, with strong and stable power output, ensuring smooth operation of each edging process. The total motor power reaches 24.5kw, which can fully meet the edging needs of glass of different thicknesses and sizes. Even in the face of thicker or larger glass, it can easily cope with it and quickly complete the edging task, greatly improving production efficiency and saving a lot of time and cost for the company.

Fine edging:

The 12 motors of Glass Straight Line Edging Machin can accurately control different grinding heads respectively, which can realize a variety of edging processes such as rough grinding, fine grinding, chamfering, chamfering and belt polishing, and can be formed in one time without multiple machine changes. Each grinding head can be finely adjusted according to the glass material and the preset edging effect, and can maintain high precision at different edging stages, ensuring that the edge of the glass after edging is smooth, rounded and flawless, meeting the requirements of high-quality glass processing, and can be used to make high-end doors and windows, glass furniture, crafts and other products.

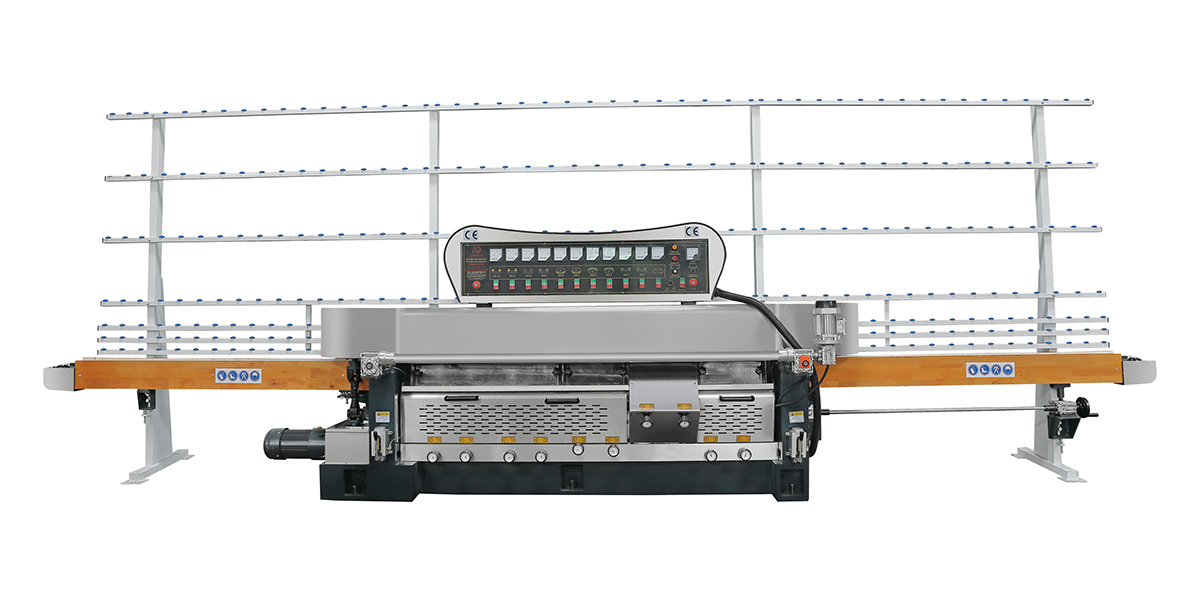

Intelligent speed regulation:

12 Motors Glass Straight Line Edging Machine adopts advanced continuously variable mechanism transmission, and the motor speed and workload can be smoothly adjusted as needed. Through frequency conversion control technology, operators can flexibly set the motor speed according to the type, thickness and edge grinding process of glass, ensuring that the speed is moderate during rough grinding to increase the edge grinding speed, and the speed is stable during fine grinding and polishing to ensure the edge grinding quality. This intelligent speed regulation function makes the machine operation more flexible, adaptable to different processing scenarios, and improves processing accuracy and consistency.

Strong adaptability:

12 Motors Glass Straight Line Edging Machine can process glass thickness ranging from 3 to 25mm, which can adapt to a variety of common glass application requirements. Whether it is thick glass for construction or thin glass for decoration, it can process accurately. Its front guide rail can be flexibly adjusted to easily match glass of different thicknesses without additional replacement of parts or complex adjustments, which greatly increases the versatility of the equipment, so that enterprises do not need to prepare multiple equipment for glass of different thicknesses, reducing procurement and maintenance costs.

Secure clamping:

The 12 Motors Glass Straight Line Edging Machine is equipped with an automatic clamping system that can firmly clamp the glass to ensure that it remains stable during the edging process. The clamping force can be automatically adjusted according to the thickness and material of the glass to prevent the glass from being damaged due to excessive force during processing, or edging deviation due to unstable clamping. The automatic clamping system also has a quick clamping function, which can shorten the clamping time, improve the working efficiency of the equipment, and ensure the continuity and safety of glass processing.

Stable operation:

The 12 Motors Glass Straight Line Edging Machine is equipped with a voltage stabilization system to effectively cope with grid voltage fluctuations and avoid motor failure or reduced processing accuracy due to unstable voltage. In industrial environments, grid voltage often fluctuates due to the simultaneous operation of equipment. This voltage stabilization system ensures that the machine always works at the rated voltage, prolongs the service life of the equipment, ensures the stability and reliability of edging processing, and allows enterprises to no longer be disturbed by grid fluctuations.

Convenient operation:

The 12 Motors Glass Straight Line Edging Machine has a simple and clear operation interface, equipped with an intuitive control panel, and clear and easy-to-understand parameter settings. Operators can master the operation methods after simple training and easily complete operations such as glass clamping and edge grinding parameter setting. In addition, its conveyor belt adopts ergonomic design, which makes glass placement and removal convenient and quick, further reducing manual operation time and labor intensity, and improving production efficiency.

Sturdy and durable:

The overall structure of 12 Motors Glass Straight Line Edging Machine is made of high-strength steel. After precision processing and strict quality control, it ensures that the equipment is still sturdy and durable under long-term high-intensity operation. The key components are all treated with wear-resistant and rust-proof treatment, which can effectively resist dust corrosion and wear generated during glass processing, reduce equipment downtime and maintenance time, reduce maintenance costs, and provide enterprises with long-term stable high-precision edge grinding processing services.

12 Motors Glass Straight Line Edging Machine Application:

Architectural glass processing:

It can be used to process the straight edges of architectural door and window glass and curtain wall glass. In the construction industry, glass doors and windows and curtain walls have extremely high requirements for the quality of glass edges. 12 Motors Glass Straight Line Edging Machine can process smooth, neat and standard straight edges to ensure the beauty and sealing of the glass after installation, and improve the energy-saving performance and service life of the building.

Furniture manufacturing field:

In the manufacture of glass furniture, such as glass coffee tables, dining tables, TV cabinets, etc., 12 Motors Glass Straight Line Edging Machine can process exquisite straight edges to improve the quality and grade of furniture. After edge grinding, the edges of glass furniture are rounded and smooth without sharp edges, which is safer to use, and can be integrated with the overall design style of the furniture to show a simple and fashionable beauty.

Automotive glass processing:

The front windshield, side window glass, etc. of the car require high-precision straight edge grinding during the production process. 12 Motors Glass Straight Line Edging Machine can meet the requirements of precision and consistency in automotive glass processing, ensure that the gap between the glass and the car body is uniform after installation, do not affect the appearance and driving safety of the car, and provide high-quality glass parts for automobile manufacturing.

Electronic display glass:

Electronic display screens such as mobile phone screens and computer monitor screens have extremely high requirements for glass processing precision. The 12 Motors Glass Straight Line Edging Machine can process precise straight edges to ensure that the screen and the frame fit tightly after the display screen is assembled without light leakage, while reducing the stress concentration on the edge of the glass and improving the impact resistance of the display screen.

Glass handicraft manufacturing:

When making glass handicrafts, such as glass vases and glass ornaments, the glass needs to be finely edged. 12 Motors Glass Straight Line Edging Machine can realize a variety of edge grinding processes to process straight edges with artistic sense, enhance the beauty and artistic value of handicrafts, and meet the high-end market's demand for the quality of glass handicrafts.

Solar photovoltaic glass processing:

Solar photovoltaic glass needs to be processed with flat and smooth straight edges to ensure the close combination of glass and solar cell modules and improve the photoelectric conversion efficiency. 12 Motors Glass Straight Line Edging Machine can process the edges of solar photovoltaic glass efficiently and accurately, meeting the photovoltaic industry's strict requirements for glass processing and promoting the development of the new energy industry.

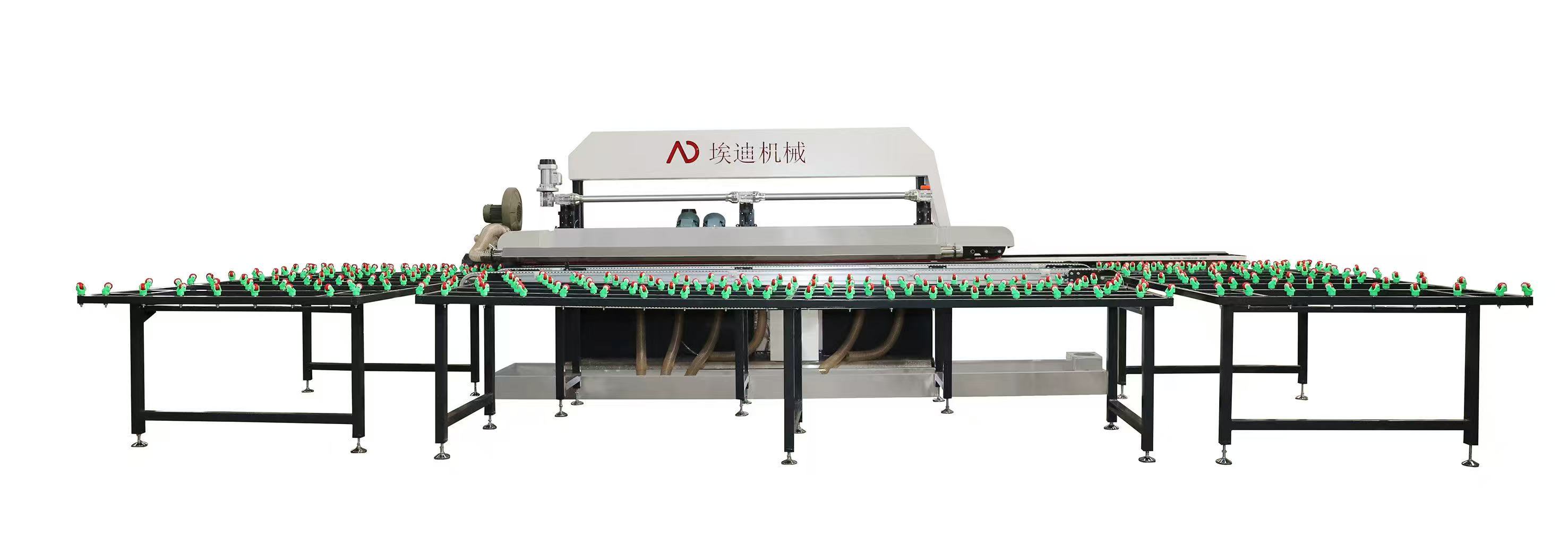

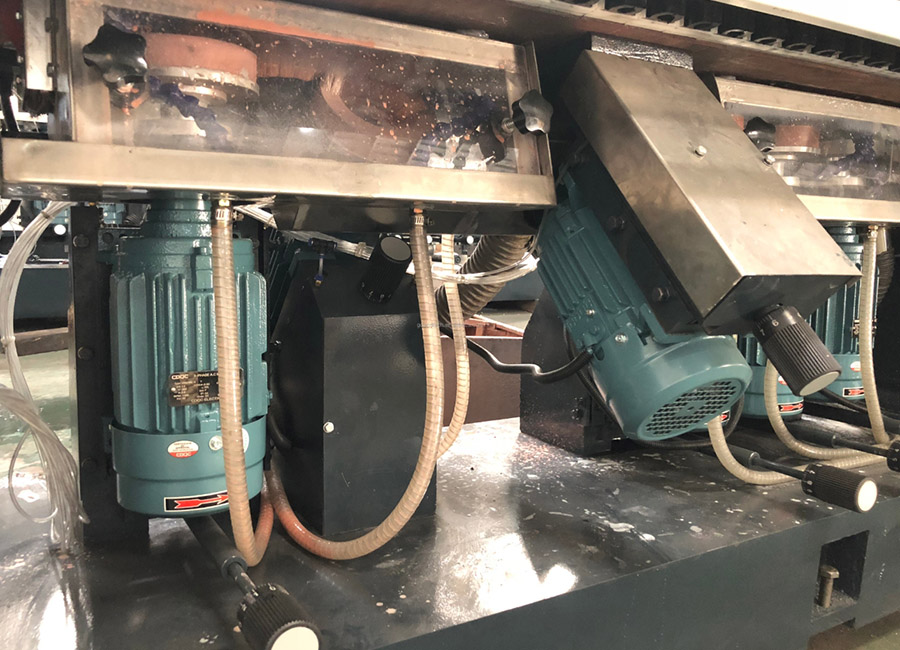

12 Motors Glass Straight Line Edging Machine Detailed Images:

Polishing system with felt wheels

Three wheels : 1 Base polishing & 2 arris polishing

Electric control can add display, can be manual adjust.