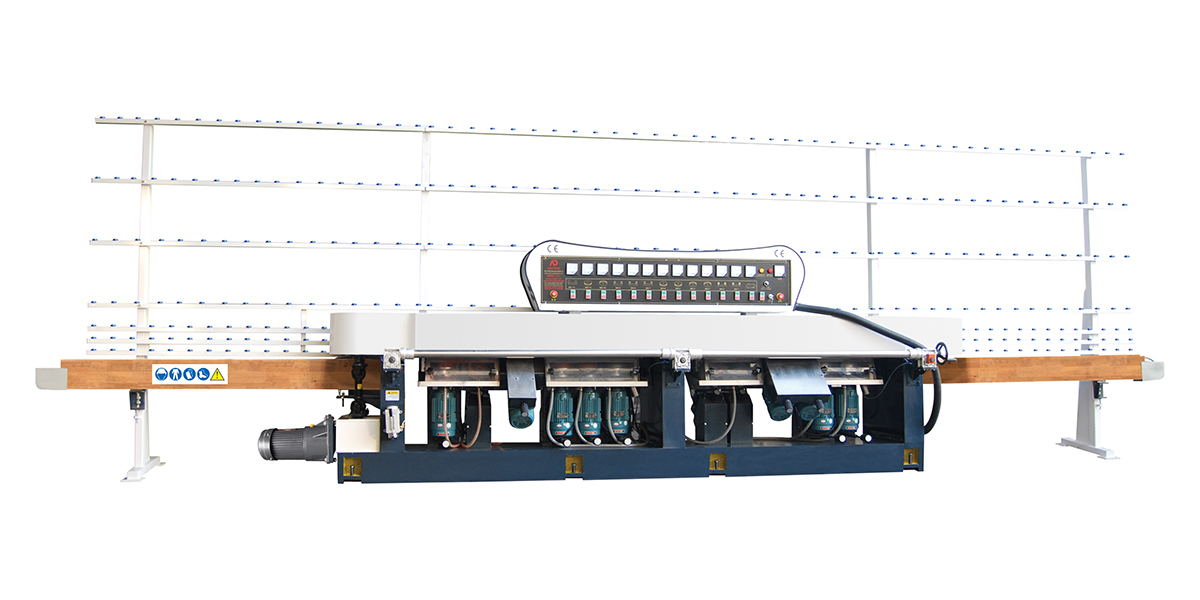

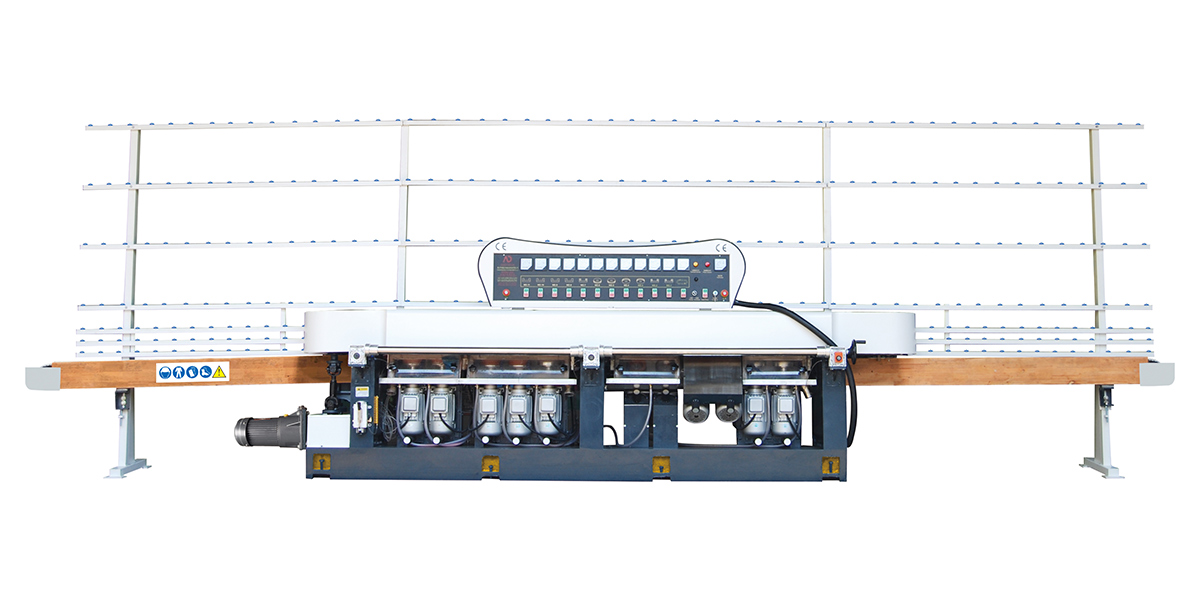

11 Motors Glass Straight Line Edging Machine

- Product Information

The 11 Motors Glass Straight Line Edging Machine is a high-precision device designed for efficient and accurate straight-line edging of glass. Equipped with 11 powerful motors, this 11 motors edging machine ensures smooth and uniform edging, enhancing the quality of the glass edges. ADZM11325 Glass straight line edging machine, suitable for grinding straight edge of different size and thickness flat glass. The coarse grinding, fine grinding, edge bottom and chambering using felt wheel polishing can be finished at one time. Frequenay control of motor speed and working load can be adjusted smoothly at will by continuously variable mechanism transmission. Adjust front rail to match different glass thickness. The machine is equipped with automatic clamping system and voltage stabilizing system. With easy operation, high precision and efficiency, this machine becomes one of indispensable equipment for glass procession. As one of the top China 11 motors edging machine suppliers, we are committed to providing exceptional products and services to our global clientele.

Introduction:

1. Suitable for grinding straight edge of different size and thickness flat glass.

2. The coarse grinding, fine grinding, chamfering and polishing can be finished at one time.

3. Working speed and working load can be adjusted smoothly by continuously variable mechanism transmission.

4. Adjust front rail to match different glass thickness.

5. The machine is equipped with automatic clamping system and voltage stabilizing system.

6. With easy operation, high precision and efficiency, this machine becomes one of indispensable equipment for glass procession.

Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADZM11325 |

| Voltage | 380V/50Hz |

| Power | 26kw |

| Glass thickness | 3-25mm |

| Feeding speed | 0.5-7m/min |

| Min size | 80×80mm |

| Weight of machine | 3200kg |

| Overall size | 7600×2500×1000mm |

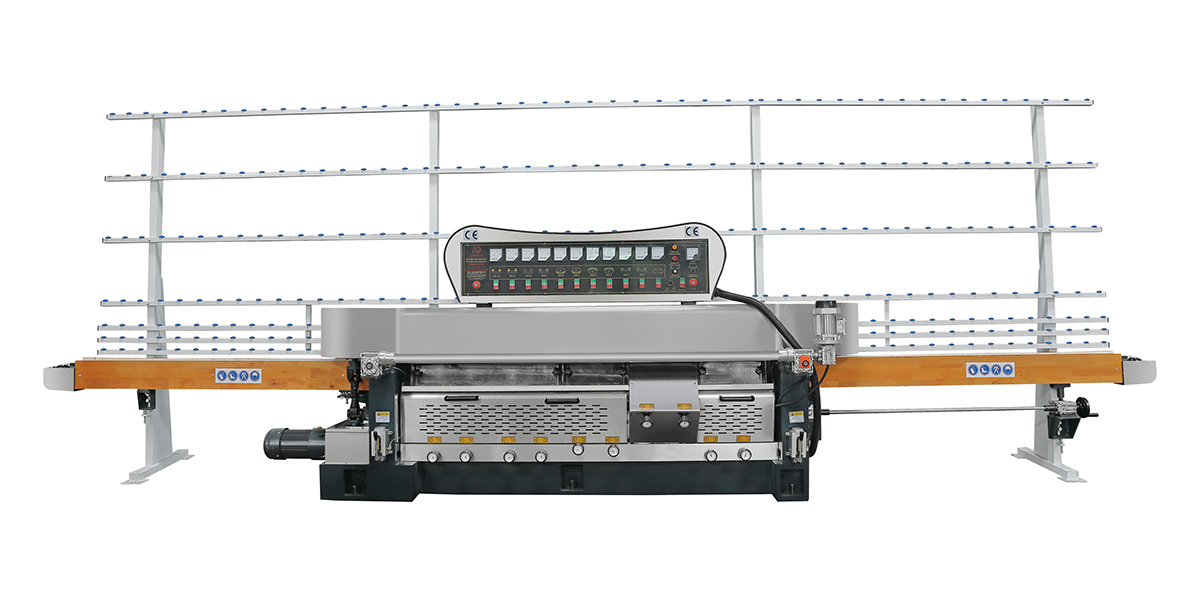

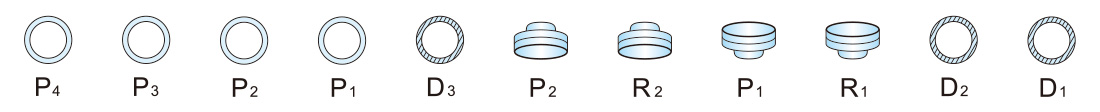

Position of Wheels:

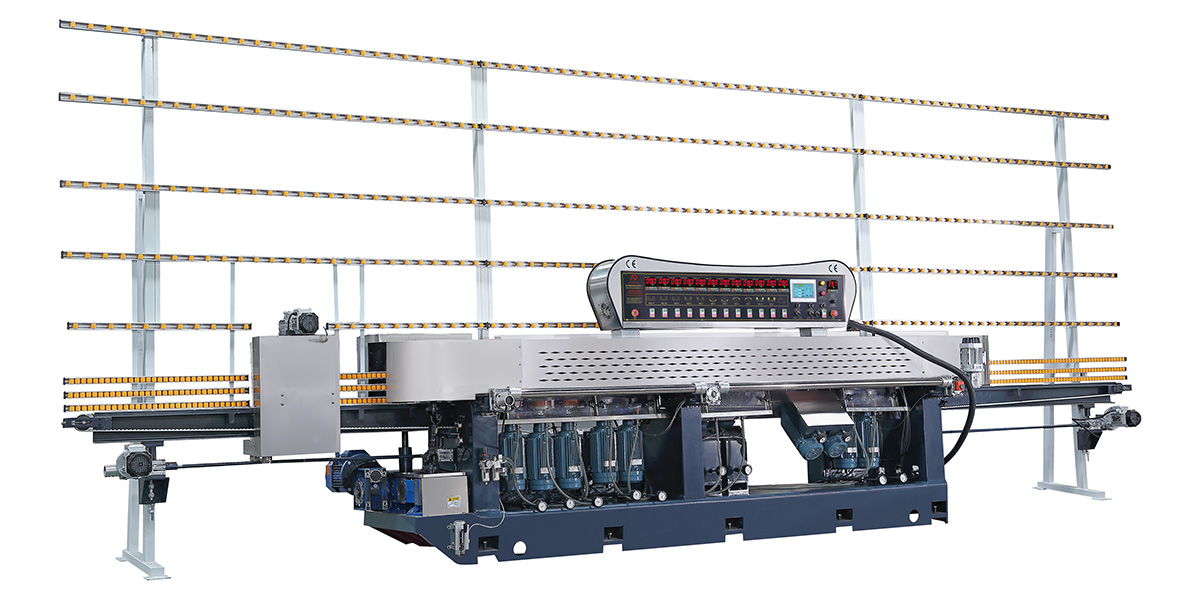

Machine Detail:

1. CE machine & CE certification, PLC control system and digital displayer available.

2. Heavy duty foundation & beams: cast steel,annealing treatment.

3. Electric device: SIEMENS, Schneider or Delixi electrical optional.

4. ABB, XINDONGYA, SNY motor optional. 380V/50Hz, 380V/60Hz, 220V/60Hz, 400V/50Hz, 415V/50Hz, optional.

5. Thicken chain transmission system, can loading 600kg big size thick glass; Beveling machine equipt synchronous belt PU chain transmission system.

6. Various high quality import grinding wheels. Suit for grind mirror, mosica, spell mirror,Low-e glass, float glass, laminated glass, tempered glass, etc.

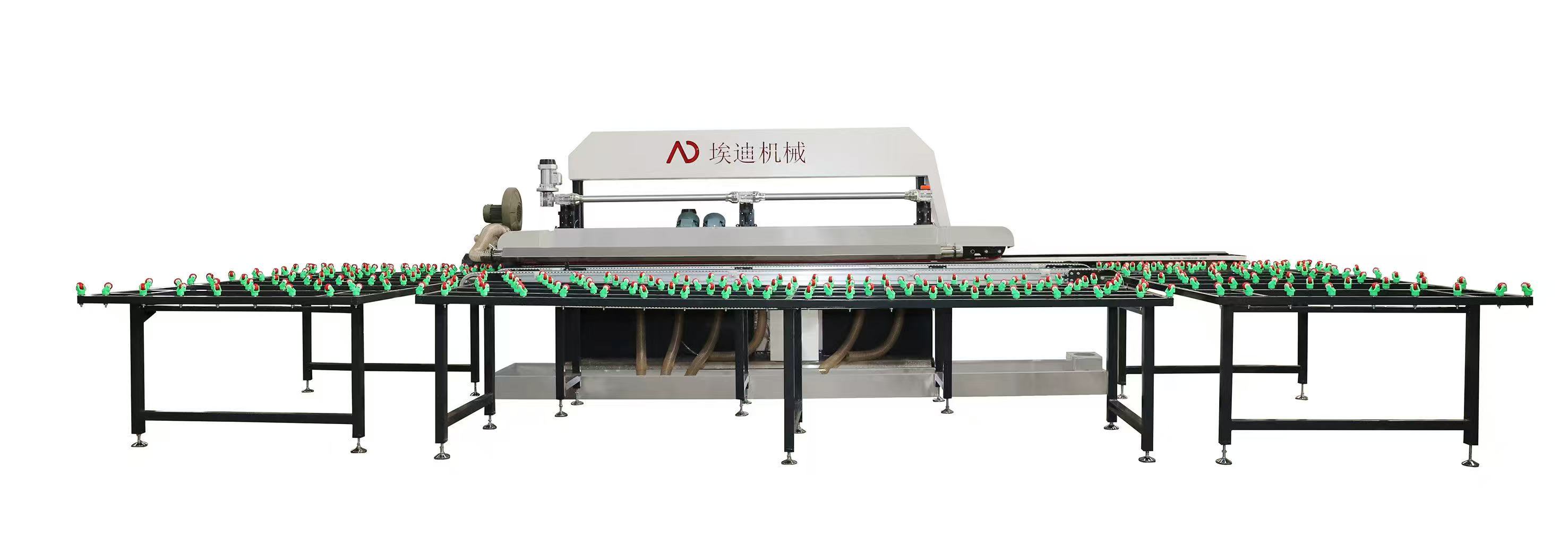

11 Motors Glass Straight Line Edging Machine is a high-precision CNC edging equipment designed for large-scale industrial production of building glass, furniture glass, automotive glass, and photovoltaic glass. Its core function is to achieve automated forming, polishing, and safe processing of glass straight edges through 11 sets of independently driven grinding units (including rough grinding, fine grinding, polishing, chamfering, and other process modules). A single processing can complete the entire process from raw burrs to mirror level accuracy, with processing efficiency increased by more than 40% compared to traditional equipment. It is suitable for mass production of medium and large-sized glass (maximum processing size ≥ 3660mm × 2440mm).

2、 Core Features and Professional Data

Multi axis linkage control system

Axis configuration: 11 independent servo motors (rated power 1.5-3.0 kW/axis) are used to drive, and synchronous response of 0.01ms level is achieved through EtherCAT bus, ensuring continuity error of rough grinding, fine grinding, polishing, chamfering and other processes of ≤± 0.05mm.

Motion accuracy: The X/Y/Z three-axis positioning accuracy reaches ± 0.02mm (ISO 230-2 standard), with a repeat positioning accuracy of ± 0.01mm. It can stably process float glass, tempered glass, and Low-E coated glass with a thickness of 3-25mm.

Processing speed: The maximum feed rate is 30m/min (coarse grinding section) and 15m/min (fine grinding/polishing section), which is 55% more efficient than traditional 8-axis equipment. The single shift production capacity (8 hours) can reach 1200-1500 square meters (taking 5mm glass as an example).

Modular Grinding Process Chain

Coarse grinding unit: using 6 sets of diamond grinding wheels (particle size 60 # -120 #), linear speed 2800-3200r/min, single-sided grinding amount ≤ 2.5mm, surface roughness Ra ≤ 3.2 μ m, meeting the requirements of rapid deburring.

Precision grinding unit: 3 sets of resin bonded diamond grinding wheels (particle size 240 # -400 #), linear speed 2200-2600r/min, edge straightness ≤ 0.1mm/m after processing, verticality error ≤ ± 0.15 °.

Polishing unit: 1 set of wool felt+cerium oxide polishing wheel (particle size W10-W5), adjustable pressure of 0.2-0.5MPa, surface glossiness after processing ≥ 90GU (60 ° angle detection), transmittance loss ≤ 0.3%.

Chamfering unit: 1 set of adjustable angle grinding wheels (0 ° -45 ° continuously adjustable), processing chamfer width of 1-8mm, corner radius of R0.5-R3mm, meeting the EU EN12150 safety glass standard.

intelligence control system

Numerical Control Interface: Equipped with a 15 inch industrial grade touch screen, it supports direct import of CAD drawings (compatible with DXF/DWG formats), automatically generates machining paths, and improves programming efficiency by 70%.

Pressure adaptive adjustment: Real time monitoring of the contact force between the grinding wheel and the glass through a pressure sensor (accuracy ± 0.01MPa), automatically compensating for processing errors caused by glass thickness fluctuations (± 0.5mm).

Energy consumption management: Equipped with variable frequency drive technology, the no-load power consumption is reduced by 40%, and the comprehensive energy consumption is ≤ 12kW · h/100 ㎡ (calculated based on 5mm glass processing), which is 25% more energy-efficient than traditional equipment.

Safety and Environmental Design

Dust recovery system: Adopting dual stage cyclone separation+HEPA filtration technology (filtration efficiency ≥ 99.97%), the dust concentration in the processing area is ≤ 2mg/m ³ (in accordance with GBZ 2.1-2019 standard), and the noise in the operating area is ≤ 75dB (A).

Emergency stop response: The entire machine is equipped with 8 sets of distributed emergency stop buttons, with a response time of ≤ 50ms and an emergency braking distance of ≤ 50mm (at a feed rate of 30m/min).

Protection level: IP54 protection for electrical cabinets, IP65 protection for motors, suitable for humid and dusty industrial environments.

3、 Application scenarios

Deep processing of architectural glass

Curtain Wall Glass: Processing C-shaped, double-sided ground edges of ultra large size (such as 3660mm × 2440mm) tempered laminated glass to meet the requirements of JGJ 102-2003 "Technical Code for Glass Curtain Wall Engineering" for edge strength and sealing.

Energy saving glass: Provides non-destructive processing solutions for Low-E coated glass, with a coating peeling rate of ≤ 0.1% during grinding, ensuring a K value (heat transfer coefficient) of ≤ 1.5W/(m ² · K) for insulated glass.

Furniture and home appliance glass

Customized products: Processing irregular sizes (such as non-standard rectangles and trapezoids) for dining table glass and refrigerator partitions, supporting artistic chamfering such as 45 ° beveled edges and rounded corners, with a single shift changeover time of ≤ 15 minutes.

High precision polishing: provides mirror level polishing for smart home appliance display panel glass, with a surface defect rate of ≤ 0.05% (tested according to ASTM D4828 standard).

Automotive and Photovoltaic Industry

Automotive glass: Processing the curved edges of sunroof glass and rear windshield (with CNC bending machine), with chamfer strength meeting FMVSS 205 standard, and impact energy resistance ≥ 50J.

Photovoltaic modules: Provide high transmittance polished edges for ultra white embossed glass, with a post processing edge breakage rate of ≤ 0.3%, ensuring a conversion efficiency loss of ≤ 0.1% for solar cell modules.

4、 Maintenance Guide

Routine maintenance

Grinding wheel cleaning: After daily processing, use a high-pressure air gun to clean the glass debris on the surface of the grinding wheel to avoid particle embedding and causing scratches during processing; Replace the cooling water (deionized water, conductivity ≤ 10 μ S/cm) every 50 hours.

Guide rail lubrication: Add ISO VG 32 grease to the X/Y/Z axis linear guide rail every week, with a dosage of 2-3ml/shaft, to ensure smooth movement.

Dust system inspection: Clean the dust box of the cyclone separator daily and replace the HEPA filter every month (mandatory replacement when the pressure difference alarm threshold is ≥ 300Pa).

Regular maintenance

Accuracy calibration: Use a laser interferometer to test the three-axis positioning accuracy every quarter. If the error exceeds the limit, adjust the grating ruler or recalibrate the servo parameters.

Electrical inspection: Check the insulation resistance of the main cable (≥ 10M Ω) every six months, tighten all wiring terminals, and replace aging frequency converter capacitors (when the capacity attenuation is ≥ 20%).

Mechanical components: Replace the synchronous belt (elongation>3%) and bearings (vibration speed>7.1mm/s) annually, and check the levelness of the bed (≤ 0.05mm/m).

Management of vulnerable parts

Grinding wheel lifespan: Coarse grinding wheel (60 #) has a machining capacity of ≤ 8000m ², fine grinding wheel (240 #) has a machining capacity of ≤ 12000m ², and polishing wheel has a machining capacity of ≤ 15000m ². It is necessary to establish a machining capacity statistics table and stock up in advance.

Sensor calibration: Pressure sensors are calibrated every six months (using standard weights for verification), and displacement sensors are tested quarterly for linear error (≤± 0.03mm).