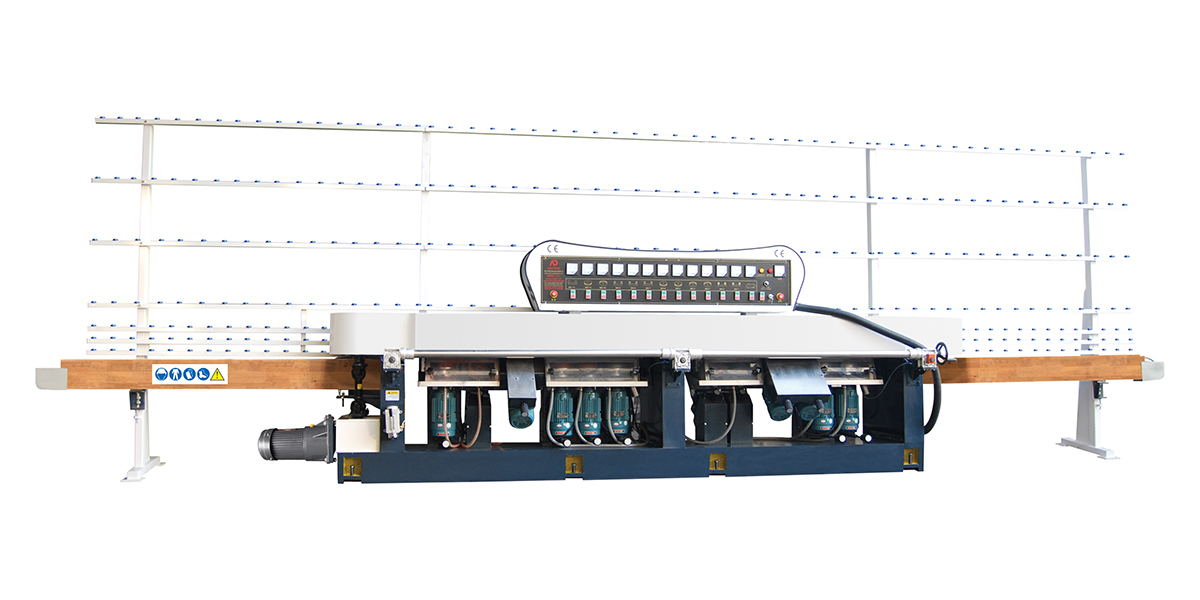

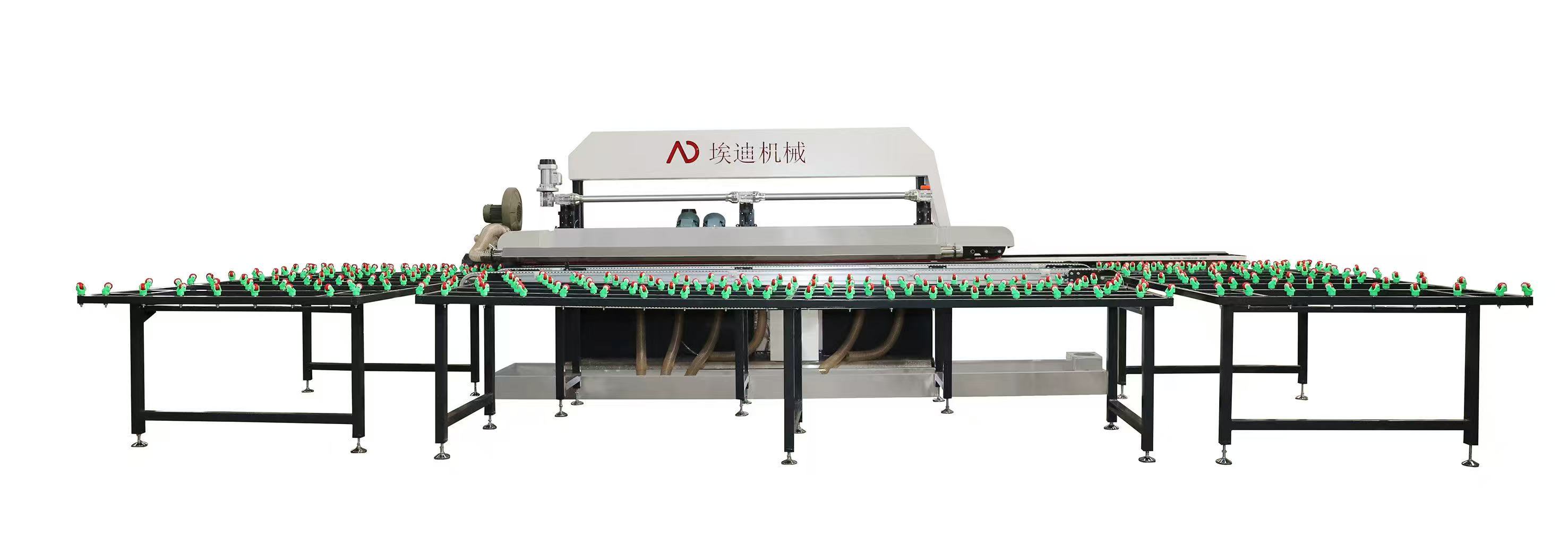

10 Motors Horizontal Glass Edge Grinding Machine

- Product Information

The 10 Motors Horizontal Glass Edge Grinding Machine is a high-performance device designed for precise glass edge processing. Ideal for a variety of glass applications, this horizontal glass edge grinding machine is built to handle both straight and shaped edges with high accuracy. ADZM10325D specialized in the processing of rhombus glass and special-shaped glass to ensure the safety of processing. Also suitable for grinding flat glass of different sizesand thicknesses. Coarse grinding, fine grinding, chamfering, and polishing processes are completed at one time. Frequency conversion speed regulation is adopted, the adjustable range is large, the speed change is stable, and the feeding speed and feeding amount can be adjusted arbitrarily during the grinding process. High processing precision, high work efficiency, convenient operation, it is an essential tool for glass processing technology. As a reputable Chinese horizontal glass edge grinding machine company, we are committed to innovation and customer satisfaction.

1. Single side edging machine Specialized in the processing of rhombus glass and special-shaped glass to ensure the safety of processing.

2. Also suitable for grinding flat glass of different sizes and thicknesses.

3. Coarse grinding, fine grinding, chamfering, and polishing processes are completed at one time.

4. Frequency conversion speed regulation is adopted, the adjustable range is large, the speed change is stable, and the feeding speed and feeding amount can be adjusted arbitrarily during the grinding process.

5. High processing precision, high work efficiency, convenient operation, it is an essential tool for glass processing technology.

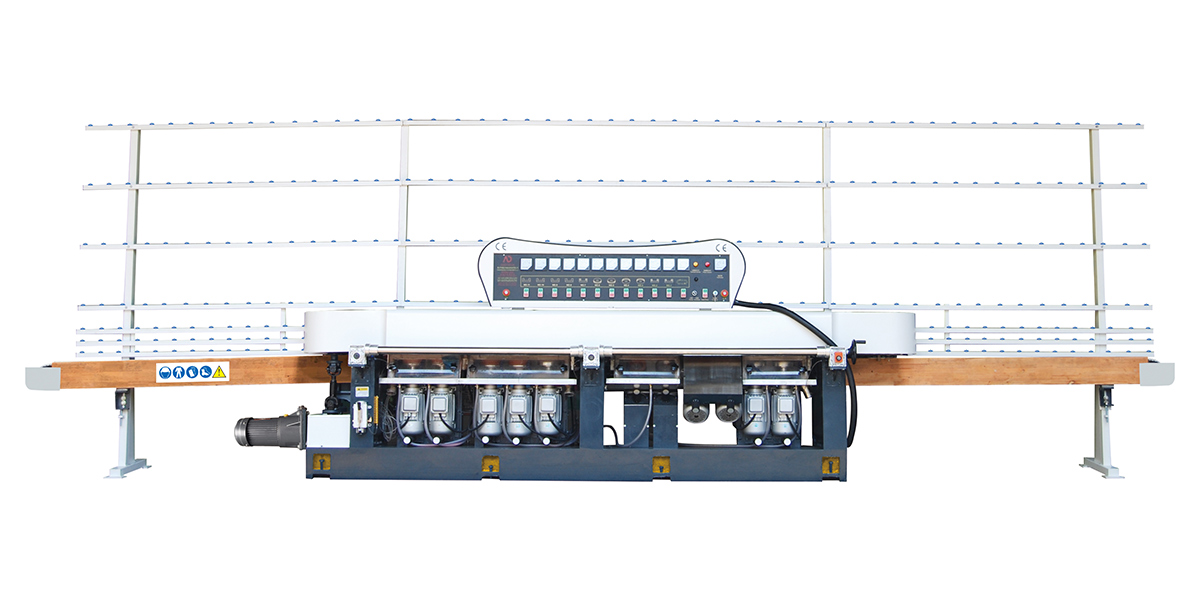

Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADZM10325D |

| Voltage | 380V/50Hz |

| Power | 31kw |

| Glass thickness | 3-25mm |

| Feeding speed | 0.5-7m/min |

| Min size | 80×80mm |

| Weight of machine | 2800kg |

| Overall size | 9000×1600×3600mm |

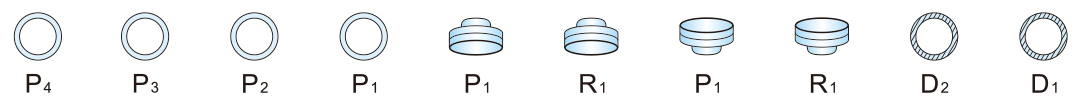

Position of Wheels:

Product Configuration:

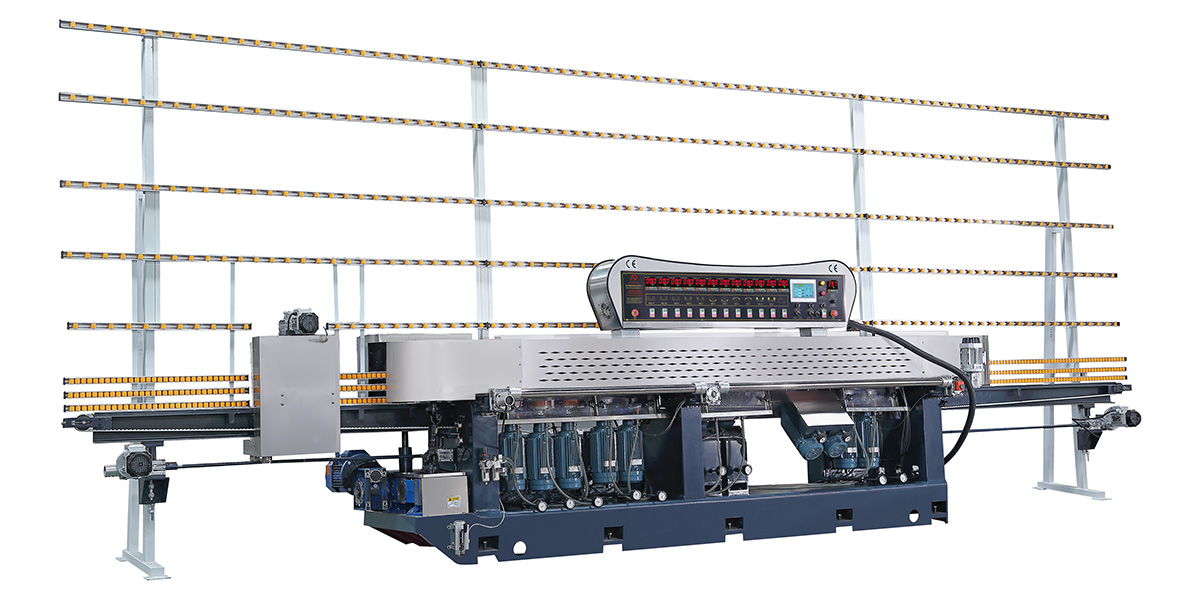

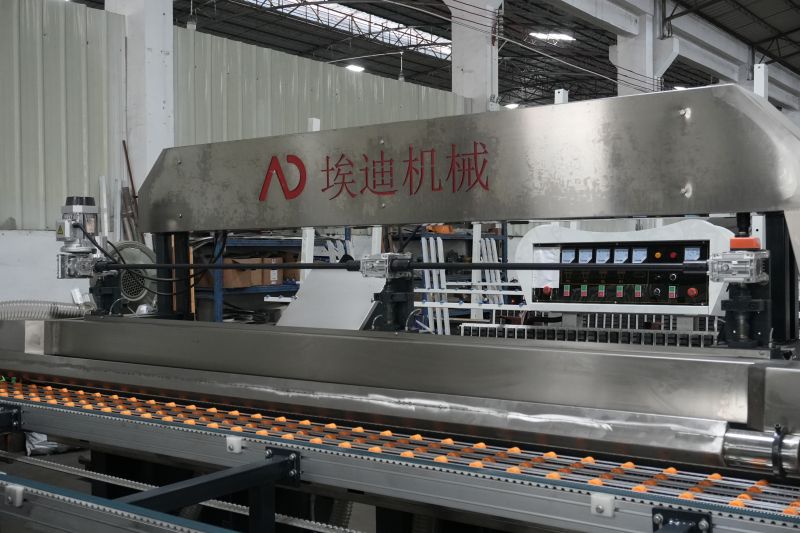

10 Motors Horizontal Glass Edge Grinding Machine is an automated equipment designed specifically for edge processing of flat glass,

Power and Drive System

Equipped with 10 sets of independent drive motors, with a total power of 22.5kW, supporting 380V/50Hz three-phase power supply, and a voltage fluctuation tolerance range of ± 10%, ensuring stable operation in unstable environments of industrial power grids.

The main grinding head motor has a power of 3kW (some models can be equipped with 4kW), and the speed can be adjusted from 0-2840rpm. It adopts variable frequency speed regulation technology to achieve precise matching between grinding force and speed.

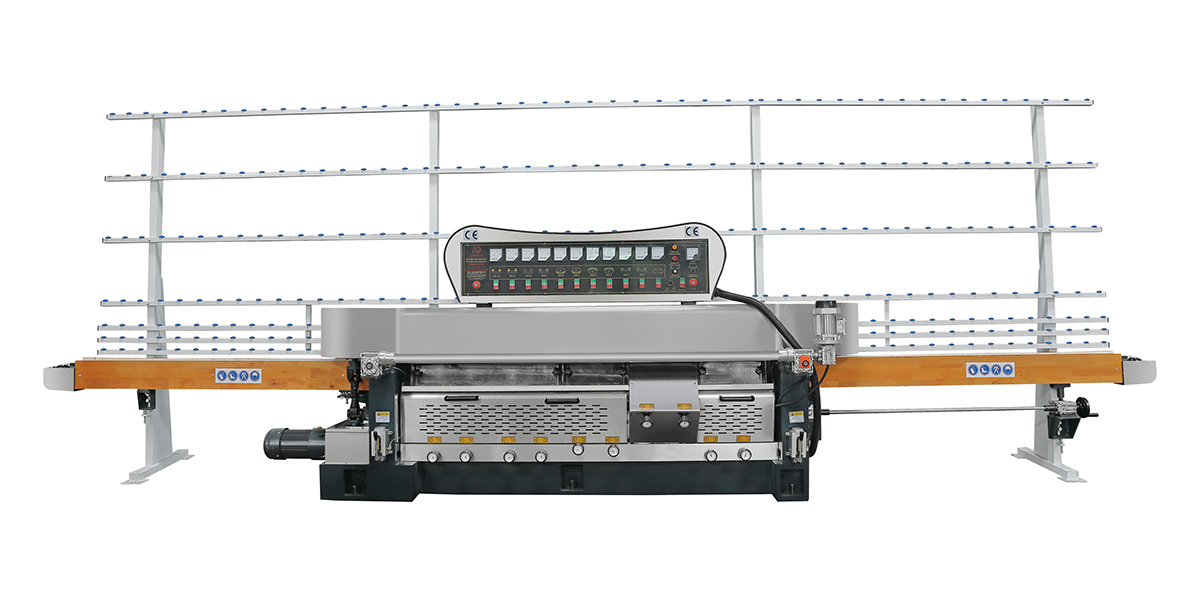

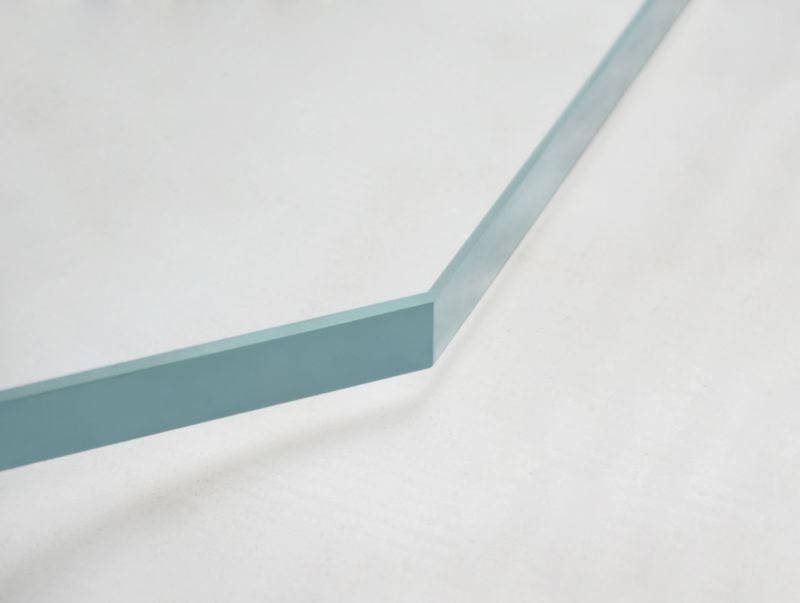

Processing capability and precision

The glass thickness range that can be processed is 3-25mm, with a minimum processing size of 50mm × 50mm and a maximum processing size of 2440mm × 3660mm, meeting diverse needs from architectural glass to home appliance panels.

The processing speed is continuously adjustable from 0.5-8m/min, with a straightness error of ≤ 0.3mm/m and an angle error of ± 0.1 °. The chamfer width is adjustable from 0-40mm, and the polishing brightness reaches Ra0.2 μ m (mirror effect).

Grinding head configuration and materials

The layout of the grinding head adopts an integrated design of "coarse grinding fine grinding polishing", equipped with diamond grinding wheels (particle size 60 # -3000 # optional) and resin bond polishing wheels (hardness D-J level), suitable for different glass materials (such as float glass and tempered glass).

The power of the bottom edge grinding motor is 2.2kW, and the power of the chamfering motor is 1.5kW. It supports quick replacement of grinding wheels, with a single wheel replacement time of ≤ 5 minutes.

Mechanical Structure and Stability

The main body is welded with Q235B steel and annealed to eliminate internal stress. The base thickness is 30mm, the crossbeam is 40mm, and the column is 25mm, ensuring that the deformation of the equipment during 24-hour continuous operation is ≤ 0.05mm.

The transmission system adopts high-precision linear guide (HGH45CA) and ball screw (SFU4010), with a repeat positioning accuracy of ± 0.02mm and a service life of ≥ 10000 hours.

2、 Typical application scenarios

This device, with its high precision and flexibility, is widely used in the following fields:

Building curtain walls and doors and windows

Provide straight and oblique edge processing for curtain wall glass of super high-rise buildings, support mass production of 12-19mm thick tempered glass, with a single shift production capacity of 1000-1500 square meters, meeting the fast delivery needs of large-scale engineering orders.

Example: For the curtain wall project of Shanghai center Building, the light transmittance of a 20000 ㎡ 15mm low radiation coated glass increased by 3% after edge polishing.

Furniture and Home Appliance Industry

For coffee tables, dining table glass countertops, and refrigerator partitions, we can process irregular glass with a minimum size of 80mm × 80mm. The chamfer R angle can be adjusted from 0.5-10mm, which meets the EU EN12150 safety standard and reduces the risk of scratches for users.

After a certain smart home brand adopted the device, the product defect rate decreased from 8% to 1.5%.

Automobiles and Rail Transit

Provide high-precision edge grinding for new energy vehicle windshields and high-speed rail side windows, support 3-8mm laminated glass processing, edge stress layer depth ≤ 0.03mm, ensuring a 40% improvement in glass impact resistance.

Photovoltaic and Electronic Glass

In the processing of solar photovoltaic panels and display cover glass, fine edge grinding of 0.5mm ultra-thin glass can be achieved, with an edge breakage rate of ≤ 0.1%, meeting the strict cleanliness requirements of the semiconductor industry.

3、 Equipment maintenance and upkeep strategy

To ensure the long-term stable operation of the equipment, the following maintenance standards should be followed:

Daily maintenance (daily)

Lubrication system: Check the oil level of the automatic oil injector to ensure sufficient lubrication of the gearbox, guide rail, screw and other parts. Use ISO VG460 gear oil and replace it every 500 hours.

Cooling system: Clean the glass debris in the water tank, check the water pump pressure (0.25-0.35MPa) to prevent the grinding wheel from burning out due to insufficient cooling.

Electrical inspection: Use an infrared thermometer to measure the surface temperature of the motor (≤ 75 ℃), clean the dust in the PLC control cabinet, and avoid program errors caused by static electricity.

Regular maintenance (every 2000 hours)

Mechanical calibration: Use a laser interferometer to detect the parallelism between the grinding head and the guide rail, with an error of ≤ 0.03mm; adjust the preload of the spindle bearing to ensure that the radial runout is ≤ 0.015mm.

Replacement of vulnerable parts: Replace grinding wheels with wear exceeding 25%, check the tension of the synchronous belt (standard value 200-250N), repair or replace broken diamond grinding blocks.

Safety inspection: Test the response time of the emergency stop button (≤ 0.15 seconds), check whether the protective cover interlock device is effective, and ensure compliance with the GB/T 15763.2 safety standard.

Long term shutdown maintenance

Rust prevention treatment: Spray rust prevention oil on the surface of the equipment, especially on exposed transmission components; Raise the grinding head to the highest position to avoid bearing deformation caused by gravity.

Environmental control: The storage environment should have a humidity of ≤ 55% and a temperature of 5-35 ℃. Use a dust cover to cover the equipment and prevent electrical components from getting damp.