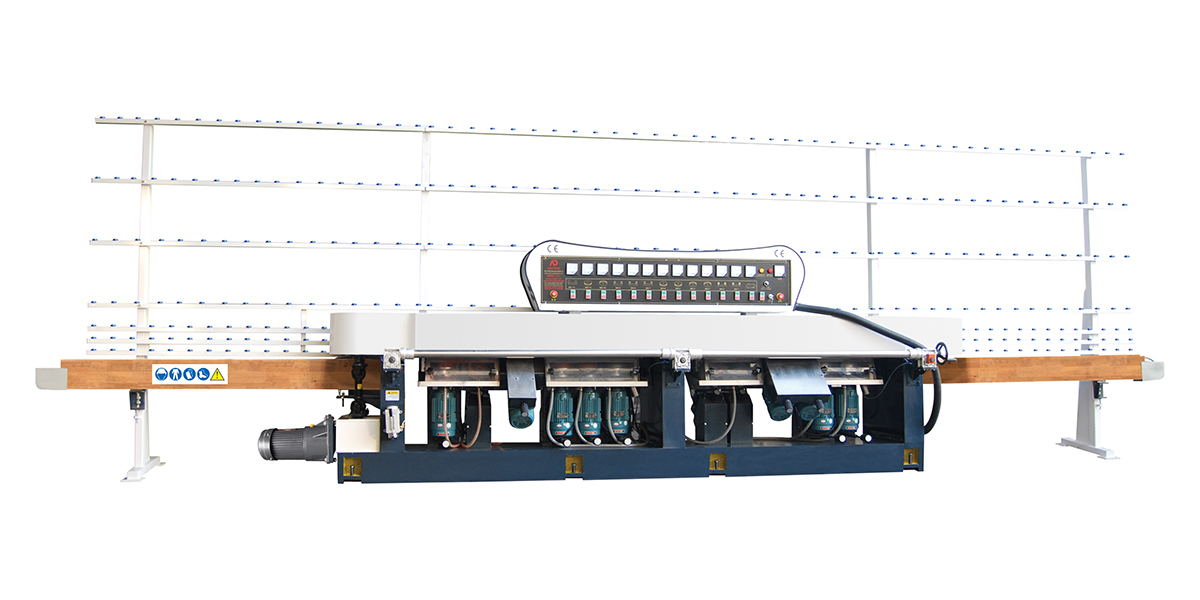

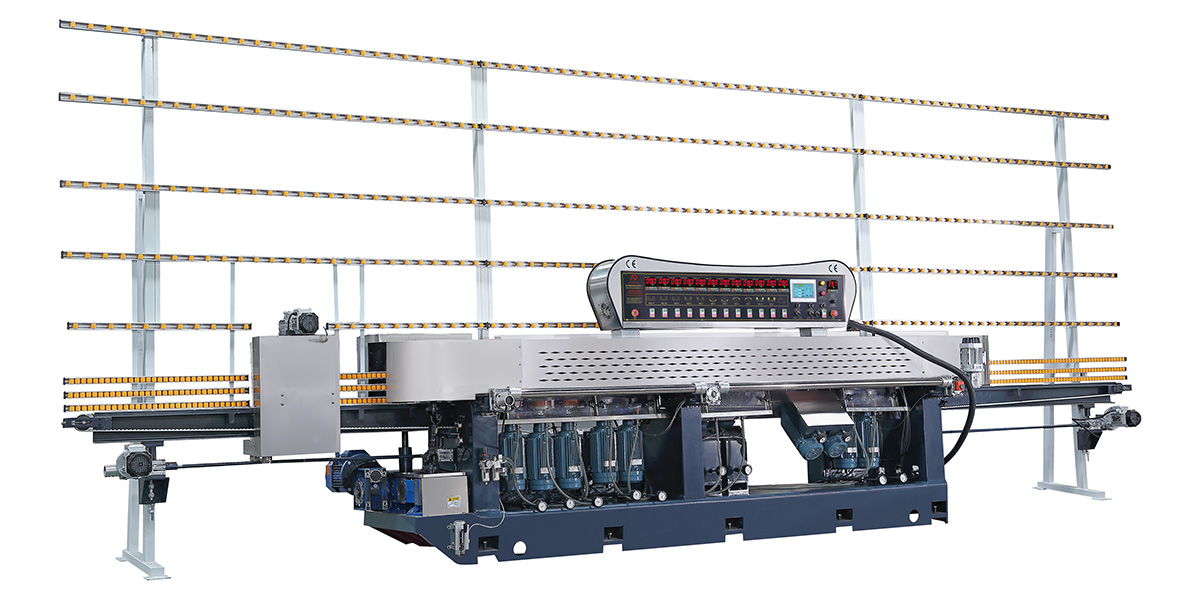

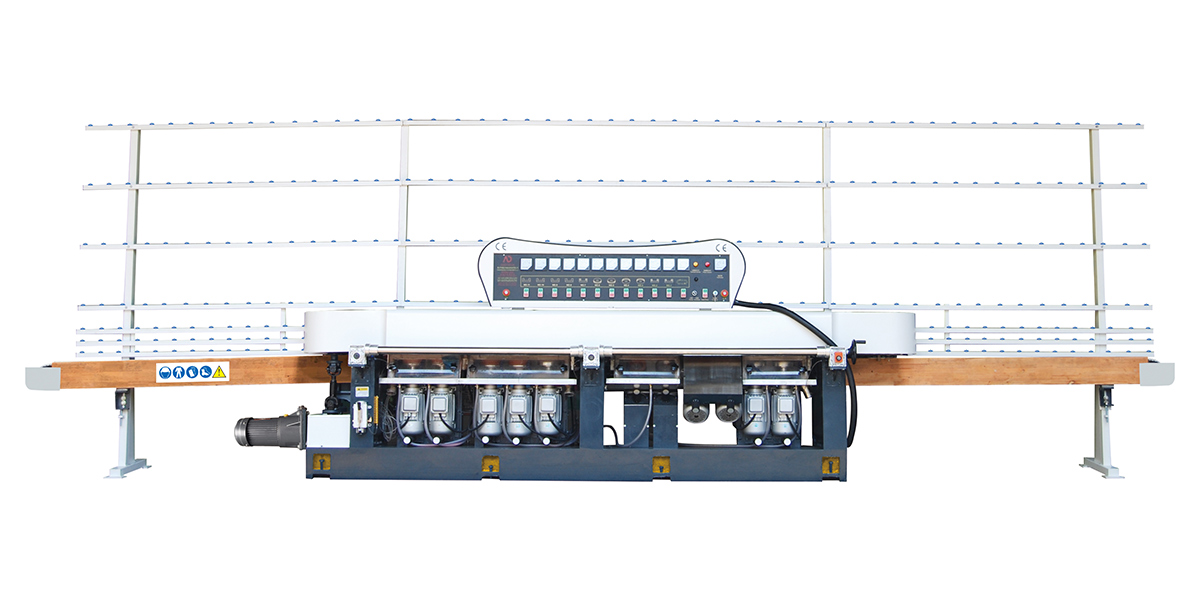

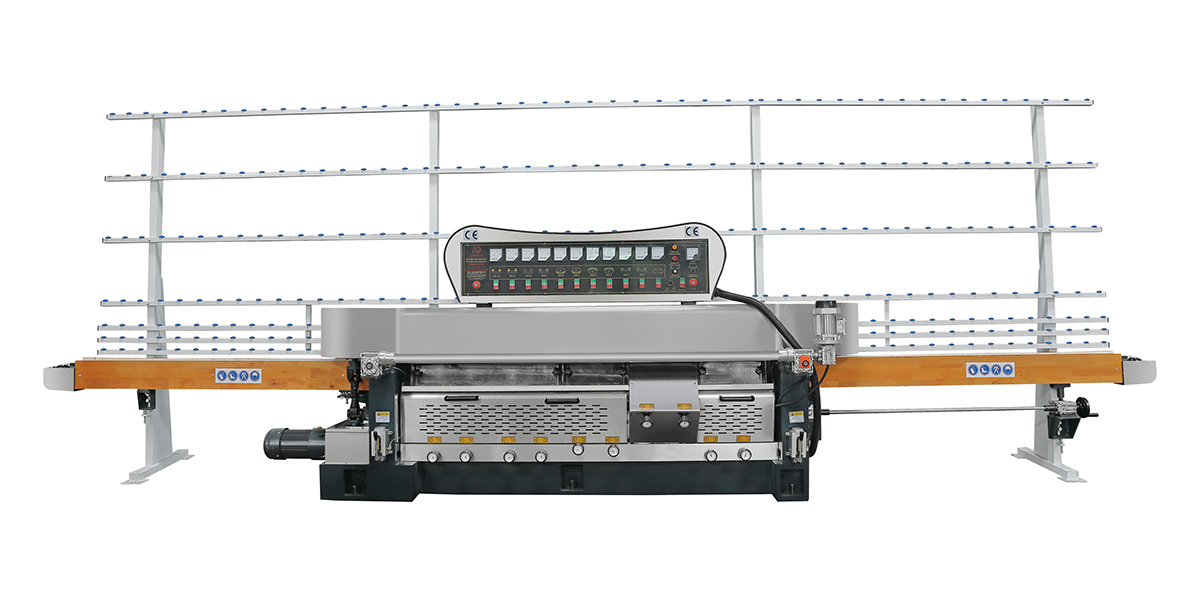

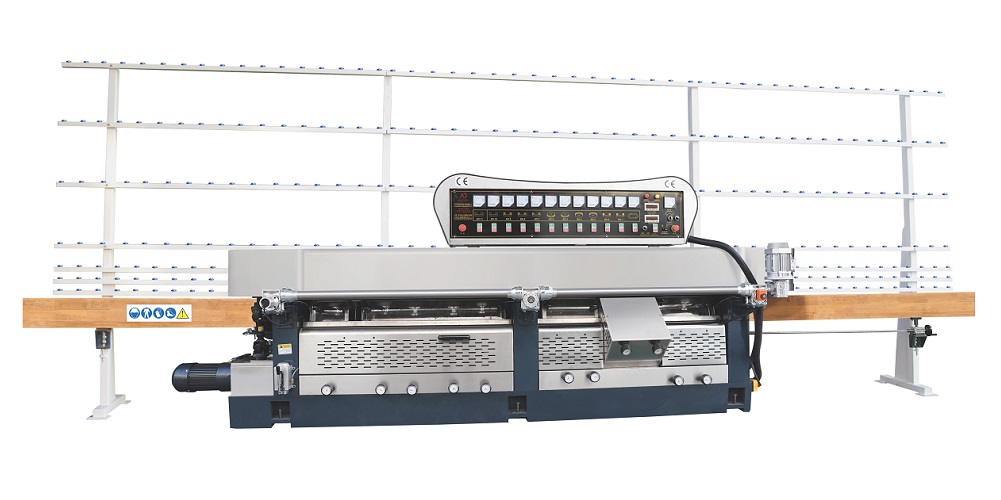

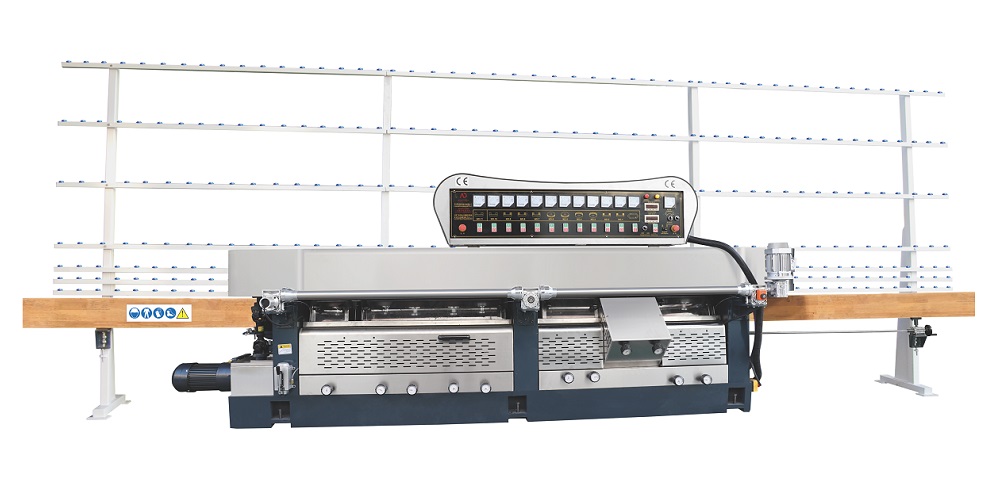

11 Motors Glass Edging Machine

- Product Information

11 Motors Glass Edging Machine is a high-precision equipment specially used for glass processing. It focuses on the processing of glass edges and realizes glass edging, chamfering and polishing through multi-motor drive. The equipment adopts advanced manufacturing technology and high-precision mechanical design to meet the processing needs of glass of different sizes and thicknesses. Its core lies in ensuring the stability and accuracy of the processing process through the coordinated work of multiple motors, thus providing efficient and reliable solutions for the glass processing industry.

4 Motors Glass Straight Line Edging Machine Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADZM11325C |

| Voltage | 380V/50Hz |

| Power | 27kw |

| Glass thickness | 3-25mm |

| Feeding speed | 0.5-5m/min |

| Min size | 60×60mm |

| Weight of machine | 3600kg |

| Overall size | 7600×2500×1000mm |

| OEM/ODM | Accept |

| Compay Nature | China Manufacturers Suppliers Factory |

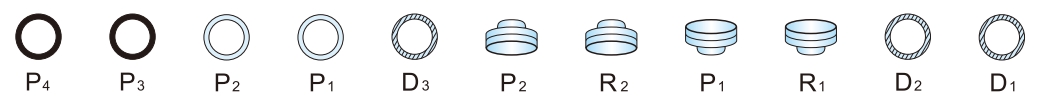

4 Motors Glass Straight Line Edging Machine Position of Wheels:

4 Motors Glass Straight Line Edging Machine Features:

High-precision grinding:

11 Motors Glass Edging Machine uses high-precision, high-hardness front and rear pressure plates to ensure that the glass remains stable during processing. The straight lines and chamfers of the ground glass are more accurate and the error range is extremely small. Its processing accuracy can reach ±0.1mm, which can meet the requirements of high-end glass processing. Whether it is architectural glass or decorative glass, it can achieve perfect edge processing.

Efficient frequency conversion speed regulation:

11 Motors Glass Edging Machine adopts frequency conversion motor speed regulation technology, which changes speed smoothly and accurately. According to the different thicknesses of glass, the speed regulation range is from 0.5m/min to 5m/min, which can quickly adapt to different processing needs. Compared with traditional motors, frequency conversion motors have higher speed regulation accuracy, lower energy consumption, and longer service life, which effectively improves the overall performance and work efficiency of the equipment.

Convenient operation design:

The front conveying guide rail of 11 Motors Glass Edging Machine can be adjusted up and down, and the operator can flexibly adjust it according to the thickness and size of the glass, which greatly improves the convenience of processing. Its operation interface is simple and intuitive, equipped with a touch screen control system, and operators can operate proficiently after simple training, effectively reducing labor costs and operating difficulties.

Large-size processing capability:

11 Motors Glass Edging Machine can process a wide range of glass sizes, with a minimum processing size of 60×60mm and a maximum processing size of several meters, which can meet the needs of different application scenarios. Whether it is small decorative glass or large architectural glass, it can be easily handled, providing strong processing capacity support for glass processing companies.

High-power drive:

11 Motors Glass Edging Machine is equipped with a powerful 27kW power system to ensure stable operation of the equipment under high load. Its 380V/50Hz voltage configuration is suitable for a variety of industrial environments and can meet the power needs of different regions. The high-power motor not only improves the processing speed, but also ensures the continuity and stability of the processing process.

Heavy-duty structural design:

11 Motors Glass Edging Machine has an overall weight of 3600kg and adopts a heavy-duty structural design to ensure stability during high-intensity processing. Its overall size is 7600×2500×1000mm, with a reasonable footprint, which is suitable for the layout of most factory workshops. The heavy-duty structure not only improves the durability of the equipment, but also reduces vibration during processing, further improving processing accuracy.

Advantages of Thick Glass Processing:

11 Motors Glass Edging Machine can process glass with a thickness of 3-25mm, covering the thickness range of most glass products on the market. Whether it is fine processing of thin glass or rough grinding of thick glass, it can be easily completed. Its powerful processing capabilities make it widely applicable in the glass processing market.

Integrated processing process:

11 Motors Glass Edging Machine can complete the rough grinding, fine grinding, chamfering and polishing of glass at one time, reducing the conversion time between processing links and improving work efficiency. The integrated processing process not only saves time and labor costs, but also ensures the continuity and consistency of processing quality.

4 Motors Glass Straight Line Edging Machine Application:

Architectural glass processing:

11 Motors Glass Edging Machine is widely used in architectural glass processing, and can meet the edge processing needs of building curtain walls, door and window glass and other products. Its high-precision edging and chamfering functions can ensure that the edges of the glass are flat and beautiful during installation, and enhance the overall appearance of the building.

Decorative glass production:

In the field of decorative glass, the equipment can process glass edges of various shapes and sizes to meet the needs of personalized design. Whether it is round, square or special-shaped glass, it can achieve high-quality edge processing through 11 Motors Glass Edging Machine, providing strong technical support for the production of decorative glass.

Automotive glass processing:

Automotive glass has extremely high requirements for processing accuracy and quality. 11 Motors Glass Edging Machine can process the edges of products such as automotive windshields and side window glass to ensure that the glass is well sealed and safe after installation. Its high-precision edging and chamfering functions can meet the strict standards of automotive glass.

Home appliance glass processing:

Home appliance glass such as refrigerator glass, TV glass, etc. requires high-quality edge processing to ensure beauty and safety. 11 Motors Glass Edging Machine can process the edges of these glass products so that they can be perfectly embedded in home appliances, improving the overall quality and service life of the products.

Furniture glass processing:

In the field of furniture glass, this equipment can process glass of various sizes for making glass coffee tables, glass cabinet doors and other products. Its integrated processing process can ensure that the glass edges are smooth and burr-free, improving the beauty and safety of furniture products.

Craft glass processing:

Craft glass has extremely high requirements for processing accuracy and process. 11 Motors Glass Edging Machine can process exquisite glass craft edges to meet the needs of the high-end craft market. Its high-precision edge grinding and chamfering functions can provide high-quality processing support for the production of craft glass.

4 Motors Glass Straight Line Edging Machine Maintenance:

Daily cleaning and inspection:

After the 11 Motors Glass Edging Machine is running, the glass debris and dust on the work surface and conveyor belt should be cleaned immediately to prevent debris from entering the mechanical parts and causing damage. Regularly check the operating status of key components such as motors, belts, gears, etc. to ensure that there is no looseness, wear or abnormal noise. Daily cleaning not only helps to extend the life of the equipment, but also ensures the stability of processing quality.

Lubrication and maintenance:

According to the frequency of use of the 11 Motors Glass Edging Machine, regularly lubricate each moving part, such as guide rails, lead screws, gears, etc. Use special lubricating oil or grease to avoid using inferior lubricants to cause component damage. Perform comprehensive lubrication and maintenance at least once a month to ensure smooth operation of the equipment and reduce wear.

Motor and electrical system maintenance:

Regularly check whether the operating current and voltage of the 11 Motors Glass Edging Machine motor are normal to avoid overload operation of the motor. Check whether the connection of the electrical circuit is firm to prevent equipment failure due to poor contact. Perform a comprehensive inspection and maintenance of the motor and electrical system every quarter to ensure the safe operation of the equipment.

Grinding wheel and tool replacement:

Grinding wheel and tool are key consumables of 11 Motors Glass Edging Machine, and their wear directly affects the processing quality. Check the wear of grinding wheel and tool regularly, and replace the seriously worn parts in time. According to the thickness and material of the processed glass, reasonably select the model of grinding wheel and tool to ensure the best processing effect.

Equipment calibration and debugging:

11 Motors Glass Edging Machine may have accuracy deviation during long-term use. Calibrate and debug the equipment regularly to ensure that the processing accuracy meets the requirements. Perform a comprehensive accuracy test and calibration every six months, and ask professional technicians to debug when necessary to ensure the processing performance of the equipment.

Environment and storage:

11 Motors Glass Edging Machine should be placed in a dry, ventilated environment without corrosive gases, avoiding direct sunlight and rain. When not in use for a long time, the power supply should be cut off, the equipment should be dustproof, and regular maintenance inspections should be performed to ensure that the equipment is always available. A good storage environment helps to extend the service life of the equipment.