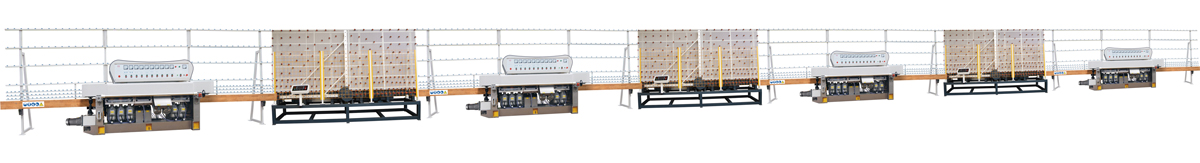

Glass Straight Edge Grinding Machine Line

- Product Information

The Glass Straight Edge Grinding Machine Line is composed of four glass edging machines and three glass transfer tables. lt is suitable for the processing and grinding of four parallel straight edges of different specifications of glass. The processes of rough grinding, fine grinding and polishing the bottom edge can be completed at one time. The transmission and overturning of this equipment adopts variable frequency motor to adjust the speed. The transmission is divided into two stages. During the glass transfer table overturning process, the back glass is temporarily stopped. After the glass is overturned, it is quickly transferred; the overturning speed can be adjusted separately according to the glass specifications. The glass straight edging machine line has a wide range of processing sizes, stable performance and strong practicability. As a top-tier China glass straight edging machine line manufacturer, we pride ourselves on our state-of-the-art production facilities, stringent quality control processes, and a highly skilled workforce.

1. Glass straight line edging product line is composed of four set straight line edging machine and three sets glass transfer table.

2. Which is suitable for grinding four parallel straight-line edge of flat glass, the coarse grinding, polishing and bottom edge processing can be finished in one time.

3. Automatic galss transfer table adopts frequency conversion motor to adjust speed for transmission and turnover.

4. The transmission is carried out in two sections, and the latter parts is briefly stopped in the process of flipping, and the transmission is rapid after the glass is flpped smoothly.

5. The trunover speed can be adjusted according to the size of the glass.

Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADZLX1525 |

| Voltage | 380V/50Hz |

| Power | 2kw |

| Max size | 1500×2500mm |

| Min size | 500×500mm |

| Glass thickness | 3-25mm |

| Feeding speed | 0.5-6m/min |

| Weight of machine | 500kg |

| Overall size | 4000×2500×1100mm |

Glass Straight Edge Grinding Machine Line is an automated equipment integrated system designed for the processing of straight edges of flat glass. It is used for continuous grinding, chamfering and polishing of straight edges of glass. The entire production line is usually composed of modules such as automatic loading system, straight edge grinding host, cleaning and drying device, automatic unloader, etc., which can realize fully automatic continuous operation.

The system uses high-precision linear transmission and multi-axis processing technology to ensure the dimensional consistency, edge flatness and safety of glass edge processing. It is one of the key equipment for the glass deep processing industry to achieve high production capacity, high quality and high automation.

Core Features:

1. High-Precision Diamond Grinding Wheels

The production line is equipped with up to 9 to 12 sets of diamond grinding wheel sets (depending on the specific model), which can complete the rough grinding, fine grinding, chamfering and polishing processes in sequence. Among them:

The rough grinding wheel uses **#60~#100** diamond particles;

The fine grinding wheel uses **#150~#240**;

The polishing wheel is an imported resin or cerium oxide polishing wheel.

The speed of each grinding wheel is adjustable, with a maximum speed of 4200 RPM, ensuring that the glass edge is processed flat, without edge collapse or cracks. The entire edge grinding accuracy can be controlled within **±0.15mm, and the edge verticality reaches >89.5°**.

2. High-precision guide rail conveying system (Precision Conveyor Chain System)

The equipment uses a reinforced alloy steel chain + rubber clamp wheel transmission system, combined with a servo motor drive, to achieve high stability and high precision of the glass plate during the conveying process.

Conveying speed range: 0.5 ~ 6 m/min (adjustable frequency conversion);

Applicable glass size: minimum glass 80×80mm, maximum up to 3000×3000mm;

Processing thickness range: 3mm ~ 25mm;

Edge deviation control: ≤±0.1mm.

The surface of the guide rail is chrome-plated for wear resistance, and the wear resistance is increased by more than 3 times, and the service life can reach more than 5 years.

3. Automatic loading and unloading system

The whole line can be equipped with intelligent robotic arms or vacuum loading/unloading systems before and after, greatly improving the degree of automation. Through photoelectric sensor positioning + PLC control system, the position and size of the glass can be accurately detected, and continuous loading, processing, and unloading can be achieved without pause.

Loading speed: ≤8 seconds per piece of glass;

Can be connected to the intelligent three-dimensional storage system to achieve intelligent logistics linkage.

4. Intelligent control and process parameter management (PLC + Touchscreen HMI)

The whole line adopts advanced PLC programmable control system and touch human-machine interface (HMI), supports multiple operating languages (Chinese/English/Spanish), and can store 100+ sets of processing parameter settings.

Visual operation interface: real-time display of grinding wheel life, processing status, and alarm information;

One-key process call function: suitable for switching processing of multiple specifications of glass;

Remote fault diagnosis module: supports remote maintenance and upgrades.

5. Glass Washing & Drying Unit

After edge grinding, connect the multi-roller brush glass cleaning + hot air drying unit to quickly remove processing residues and water stains, ensure the cleanliness of the glass surface, and facilitate subsequent tempering or silk-screen printing processes.

Cleaning speed: 5~15m/min;

Drying temperature: adjustable, up to 80℃;

Water circulation filtration system: water-saving and environmentally friendly, filtration accuracy<5μm.<>

Application Scenario Analysis:

1. Architectural glass industry

Architectural curtain walls, partition glass, lighting glass, etc. use a large amount of edge-grinded glass to prevent edge cracks and improve aesthetics. The straight edge grinding machine production line is suitable for continuous processing of large-size glass and meets the operational needs of high-capacity architectural glass manufacturers.

Applicable glass types: Low-E glass, hollow glass original sheet, fireproof glass

✔Typical customers: curtain wall processing plant, large glass deep processing center

2. Furniture and decorative glass field

Furniture glass such as coffee table glass, cabinet door glass, bookcase glass, mirror, etc. have high requirements for edge safety and aesthetics. Straight edge grinding machine can provide soft edge processing of chamfering + polishing to prevent bumps and injuries and improve product texture.

Advantages: Precise control of chamfer width (customizable 3~5mm angle), polishing effect brightness reaches more than 90% reflectivity

Common processing size: 500×500mm~2000×1000mm

3. Home appliance glass processing

Such as refrigerator door glass, washing machine control panel, microwave oven window glass, etc., standardized edge grinding is required before assembly to ensure that the glass edge is flat and not cracked, and adapt to embedded installation requirements.

Application materials: black tempered glass, coated glass, colorful glass

Feature requirements: high precision (±0.1mm), temperature difference impact resistance, no cracks

4. Photovoltaic and new energy glass applications

Photovoltaic glass or BIPV panels have special requirements for edge processing (edges need to be rounded or chamfered to improve wind pressure resistance and safety). The straight edge grinding machine line can be equipped with a customized chamfering module to achieve R angle or C angle processing, effectively reducing stress concentration during assembly.

Processing thickness range: 3.2mm~5mm (photovoltaic panel standard)

Daily processing volume: up to 3,000 square meters/day, meeting large-scale order needs

5. Deep processing transit and whole line supporting production

Straight edge grinding line is often used in the pre-processing link before tempering, and can also be used as a process before printing, lamination, and hot bending, suitable for various deep processing production lines.

Can be seamlessly connected with tempering furnaces, cleaning lines, sprayers, and laser cutting systems

The full line length is usually 10~18 meters, and the configuration plan can be customized according to the workshop layout

Machine Detail:

Packaging & Shipping: