Automatic Horizontal Glass Drilling Machine

- Product Information

Glass processing plays an indispensable role in many fields, and Glass Drilling Machine, as a professional glass processing equipment, provides efficient and accurate solutions for glass drilling and other processing procedures. It can meet the processing needs of glass of different thicknesses and sizes, ensure that the processed holes meet strict quality standards, and lay a solid foundation for the subsequent processing and application of glass products. Whether it is architectural decorative glass, automotive glass, or electronic equipment glass, it is inseparable from the fine processing of Glass Drilling Machine. With its stable performance and reliable processing effect, it occupies an important position in the glass processing industry and promotes the continuous progress and development of glass processing technology.

Automatic Horizontal Glass Drilling Machine Introduction:

Adopt pneumatic clamping glass.

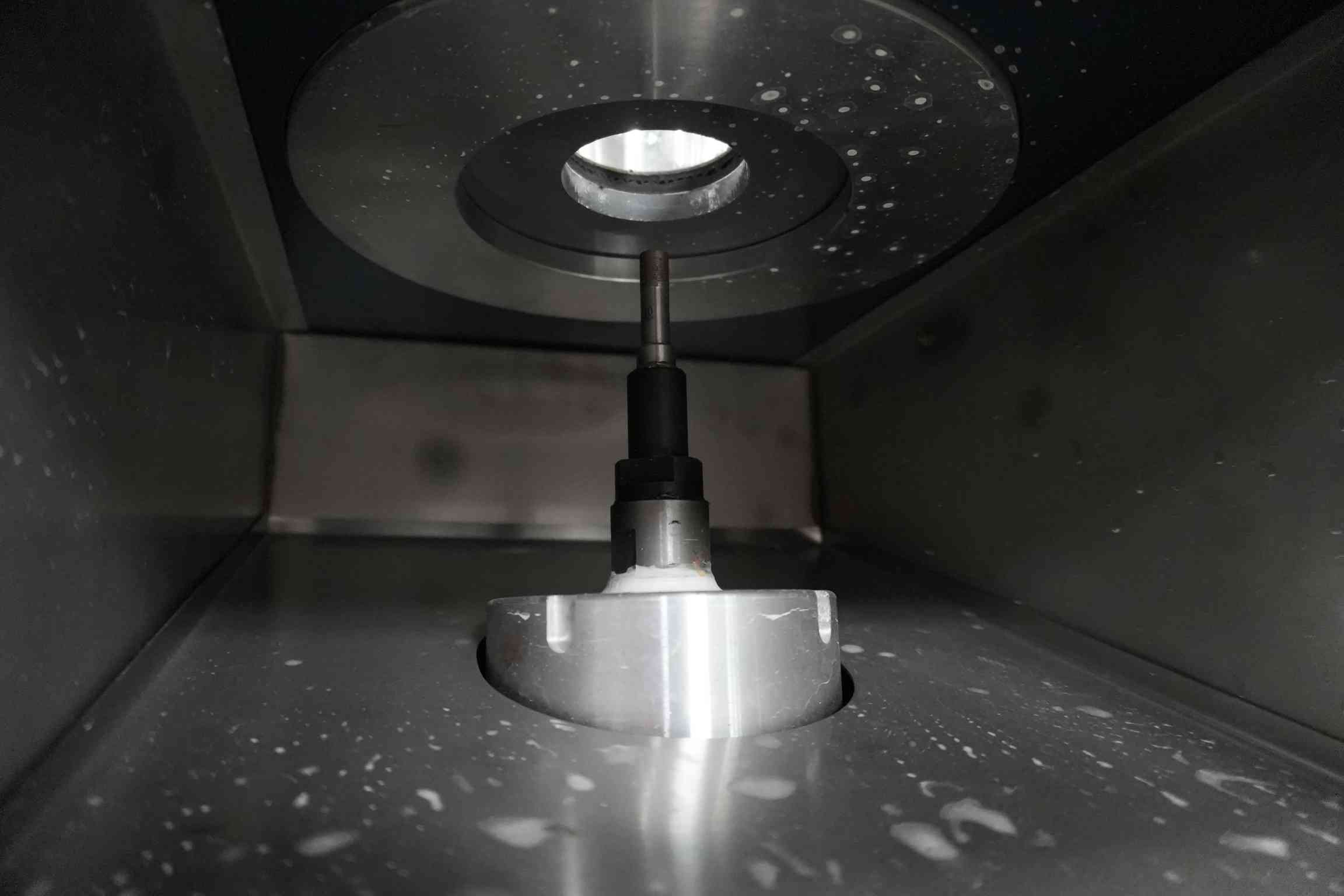

Upper and lower drilling head drill at sequency.

Feeding automatically, workable table can elevate pneumatically.

With wide machining size range.

High efficiency and easy operation.

Automatic Horizontal Glass Drilling Machine Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADYM4325 |

| Voltage | 380V/50Hz |

| Power | 3.5kw |

| Maximum processing width | 2600×1800mm |

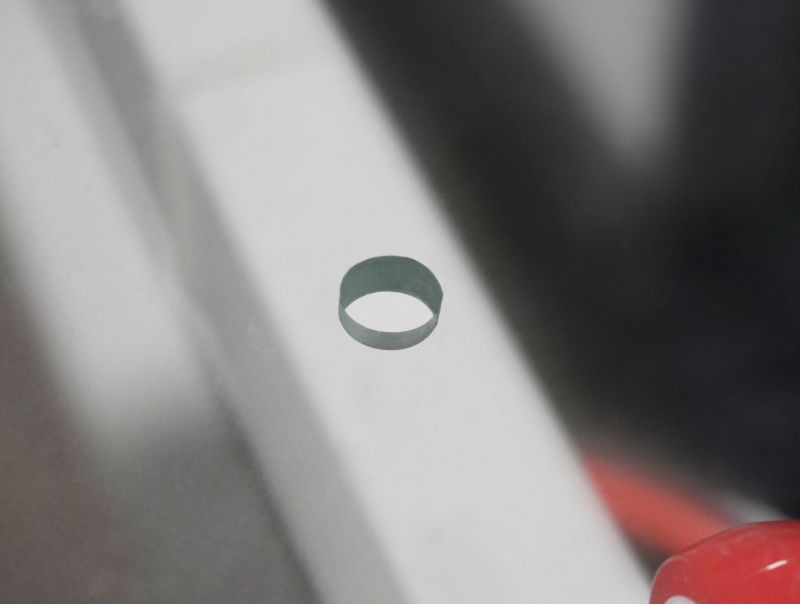

| Drilling diameter | Φ4-Φ220mm |

| Glass thickness | 3-25mm |

| Feeding speed | 1.5-6m/min |

| Weight of machine | 1000kg |

| Overall size | 2600×2500×1000mm |

Automatic Horizontal Glass Drilling Machine Details:

1. CE machine & CE certification, PLC control system and digital displayer available.

2. Heavy duty foundation & beams: cast steel,annealing treatment.

3. Electric device: SIEMENS, Schneider or Delixi electrical optional.

4. ABB, XINDONGYA, motor optional. 380V/50Hz, 380V/60Hz, 220V/60Hz, 400V/50Hz, 415V/50Hz, optional.

5. Thicken chain transmission system, can loading 600kg big size thick glass. Beveling machine equipt synchronous belt PU chain transmission system.

6. Various high quality import grinding wheels. Suit for grind mirror, mosica, spell mirror, low-e glass, float glass, laminated glass, tempered glass, etc.

Automatic Horizontal Glass Drilling Machine Features:

High degree of automation:

Automatic Horizontal Glass Drilling Machine adopts advanced automatic control system, which can realize automatic feeding of glass. Its automated operation process greatly reduces manual intervention and improves processing efficiency and processing accuracy. During the processing, the equipment can automatically complete a series of operations such as positioning, clamping, and drilling of glass according to the preset program, ensuring that each processing step is accurate and correct, effectively avoiding processing errors caused by human factors, and making the glass processing quality more stable and reliable.

Firm and reliable clamping:

Automatic Horizontal Glass Drilling Machine adopts pneumatic clamping of glass, which has the advantages of uniform, stable and adjustable clamping force. The pneumatic clamping system can flexibly adjust the clamping force according to the thickness and material of the glass, ensuring that the glass is firmly fixed on the workbench during the processing without loosening or displacement. Even during high-speed drilling, the glass can remain stable, thereby ensuring the accuracy and quality of drilling, and at the same time effectively protecting the glass from damage caused by improper clamping.

Wide range of processing:

Automatic Horizontal Glass Drilling Machine has a wide range of processing sizes, with a maximum processing width of 2600x1800mm, which can meet the processing needs of glass of different specifications. Whether it is large-scale architectural glass, large-scale automobile windshields, or other large-scale glass products, they can all be efficiently drilled on this machine. In addition, its drilling diameter range is ⌀4-⌀220mm, which can adapt to the processing requirements of holes of different diameters, whether it is a tiny decorative hole or a larger installation hole, it can easily cope with it, providing great flexibility for glass processing.

Efficient drilling performance:

Automatic Horizontal Glass Drilling Machine is equipped with upper and lower drill bits, which can perform drilling operations in sequence. This unique drilling method greatly improves drilling efficiency. During the processing process, the upper and lower drill bits can drill the glass at the same time, reducing the processing time and the idling time of the equipment. At the same time, its feed speed is 1.5-6m/min, which can be adjusted according to different processing requirements, further improving the processing efficiency. Under the premise of ensuring the processing quality, it can quickly complete the drilling of a large number of glasses, meeting the needs of modern glass processing enterprises for high-efficiency production.

Convenient and simple operation:

The operation interface of Automatic Horizontal Glass Drilling Machine is simple and intuitive, and easy to use. The operator of the equipment can master the operation method after simple training, without complex operation skills and professional knowledge. In the actual operation process, the various settings of the equipment and the start of the processing program can be completed through simple button or touch screen operation. In addition, the equipment is also equipped with a liftable workbench, which is pneumatically controlled, and the operation is convenient and fast. The height of the workbench can be quickly adjusted according to the thickness of the glass and the processing requirements, making the processing process smoother and further improving the convenience of operation.

Stable and reliable performance:

Automatic Horizontal Glass Drilling Machine uses high-quality electrical components and mechanical parts to ensure the stability and reliability of the equipment during long-term operation. Its voltage is 380V/150Hz and its power is 3.5kw, which can meet the normal operation requirements of the equipment, and at the same time ensure that the equipment will not have unstable voltage or insufficient power during operation. The structure of the equipment is reasonably designed, and the mechanical parts have been precisely processed and strictly quality inspected. It has good wear resistance and fatigue resistance, and can operate stably in a high-intensity processing environment, reducing the occurrence of equipment failures, and reducing the maintenance cost and downtime of the equipment.

Wide range of applicable glass:

Automatic Horizontal Glass Drilling Machine can process glass with a thickness range of 3-25mm, covering a variety of glass materials from thin glass to thick glass. Whether it is common ordinary glass or glass of special materials, such as tempered glass, laminated glass, etc., it can be processed on this equipment. This enables the equipment to meet the needs of different industries for glass processing, such as the processing requirements of the construction industry for thick glass, and the processing requirements of the electronics industry for thin glass, and has a wide range of applicability.

Compact equipment structure:

Although the Automatic Horizontal Glass Drilling Machine has strong processing capabilities and a wide range of processing, its overall structural design is compact and occupies a relatively small area. The overall size of the equipment is 2600x2000x1800mm and the weight is 1000kg, which is convenient for the installation and layout of the equipment while ensuring the performance of the equipment. This compact structural design enables the equipment to better adapt to the spatial conditions of different production sites. Even in a processing workshop with limited space, it can be easily installed and used, which improves the practicability of the equipment.

Automatic Horizontal Glass Drilling Machine Application:

Architectural glass processing:

In the field of construction, glass is widely used, such as building curtain walls, door and window glass, interior partitions, etc. Automatic Horizontal Glass Drilling Machine can be used to drill holes in architectural glass to meet various fixing and connection requirements during glass installation. For example, when installing a glass curtain wall, it is necessary to drill holes in the glass to install connectors. The equipment can quickly and accurately complete the drilling work to ensure the installation quality and safety of the glass curtain wall. At the same time, the equipment can also easily cope with the processing of large-scale building door and window glass, improve the processing efficiency of door and window glass, and provide strong support for the smooth progress of construction projects.

Automotive glass manufacturing:

Automotive glass is an indispensable and important component in automobile manufacturing. Its quality and processing accuracy are directly related to the safety performance and comfort of the car. In the production process of automotive glass, Automatic Horizontal Glass Drilling Machine can be used to process the installation holes of automobile windshields, window glass, etc. These holes are used to install parts such as wipers, rearview mirrors, and window lifters. The equipment can ensure the accuracy and quality of drilling, ensure the close fit between automotive glass and parts, and improve the overall performance and safety of the car. In addition, the equipment can also process holes of various special shapes and sizes according to the design requirements of automobile manufacturers to meet the processing needs of automobile glass of different models.

Furniture glass production:

Glass furniture is loved by consumers for its unique beauty and fashion, such as glass coffee tables, glass dining tables, glass display cabinets, etc. In the production process of furniture glass, the glass needs to be drilled to install support frames, hardware, etc. Automatic Horizontal Glass Drilling Machine can meet the high-precision requirements of furniture glass processing, and the edges of the processed holes are smooth and burr-free, ensuring the appearance quality and performance of furniture glass. The glass furniture processed by this equipment is not only beautiful, but also has good stability and safety, providing reliable processing guarantee for the production of furniture glass.

Electronic glass manufacturing:

With the continuous development of electronic technology, the screens and panels of electronic equipment are increasingly made of glass, such as mobile phone screens, computer monitors, TV screens, etc. These electronic glasses need to be drilled with high precision to install electronic components and connect circuits. Automatic Horizontal Glass Drilling Machine has high-precision processing capabilities, which can meet the strict requirements of electronic glass processing, process tiny and precise holes, and ensure the installation accuracy and reliability of electronic components. The automated processing method of the equipment can also improve the production efficiency of electronic glass, reduce production costs, and provide efficient processing solutions for electronic glass manufacturers.

Decorative glass processing:

In the field of interior decoration, decorative glass is widely used in background walls, partitions, screens and other parts. Through drilling processing, various exquisite patterns and shapes can be produced, such as decorative patterns composed of circular, square, oval and other holes, adding an artistic atmosphere to the interior space. Automatic Horizontal Glass Drilling Machine can process holes of various shapes and sizes according to design requirements to achieve personalized customization of decorative glass. The processing accuracy and stability of the equipment ensure the beauty and consistency of the decorative pattern, so that the decorative glass can better meet the creative needs of interior designers and enhance the overall effect of interior decoration.

Craft glass production:

Craft glass is loved by people for its unique artistic value and ornamental value, such as glass crafts, glass lamps, etc. In the process of making craft glass, drilling is one of the common processes, which is used to make lamp holes for glass lamps, decorative holes for glass crafts, etc. Automatic Horizontal Glass Drilling Machine can flexibly adjust the diameter and position of the drilling holes according to the design requirements of the craft glass, and process various exquisite holes to meet the complex process requirements of craft glass production. The high-precision processing capability of the equipment can ensure the processing quality of craft glass, make craft glass works more exquisite and beautiful, and enhance their artistic value and market competitiveness.