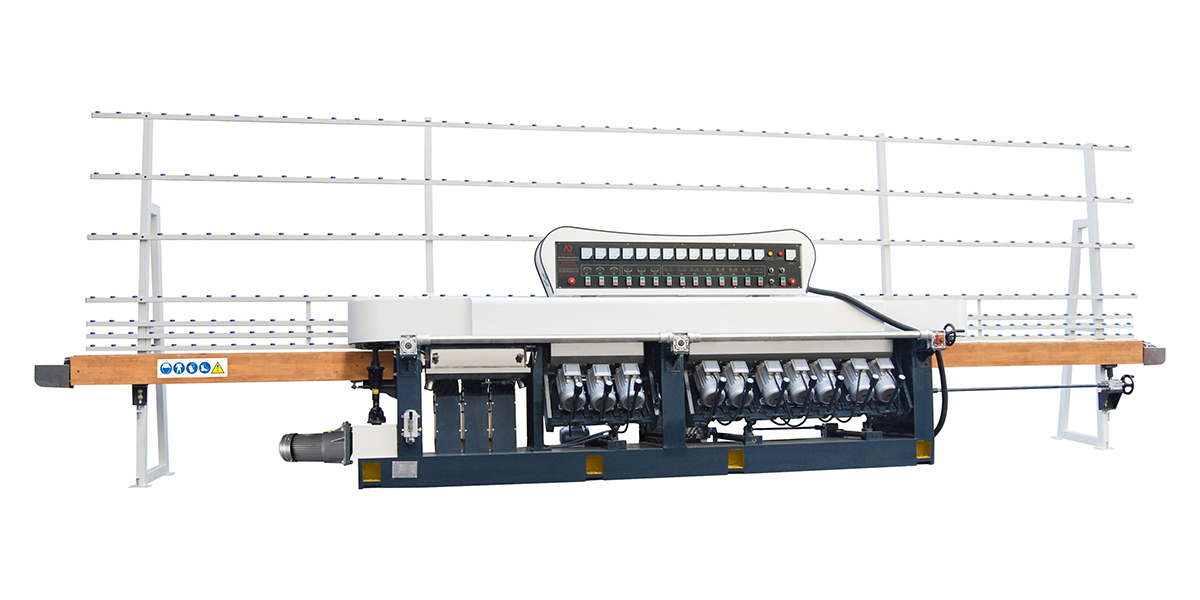

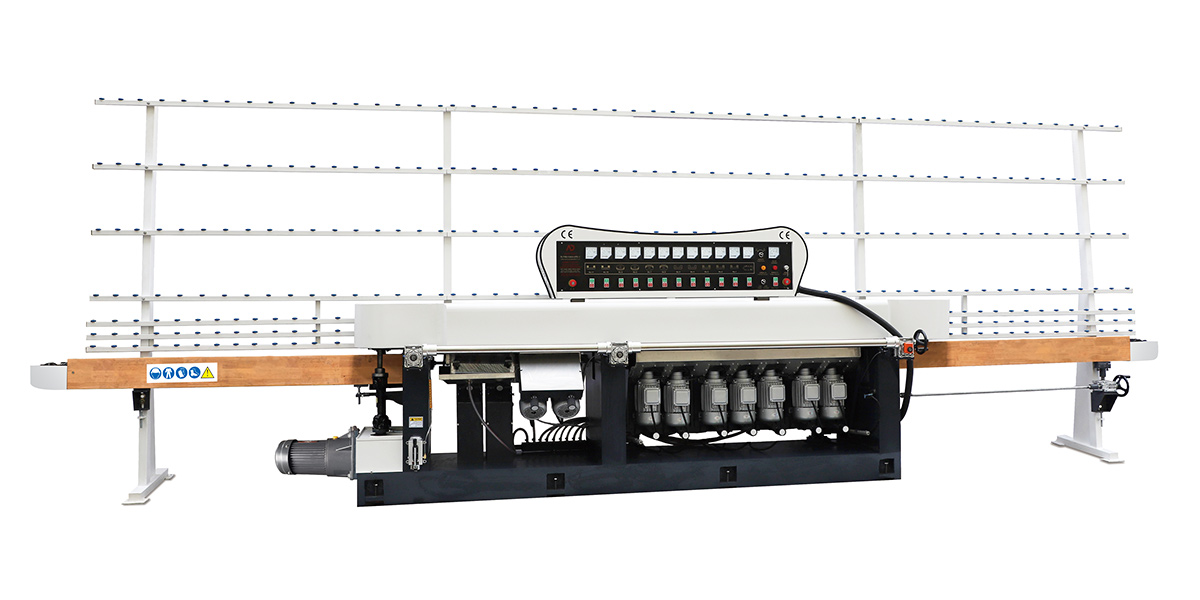

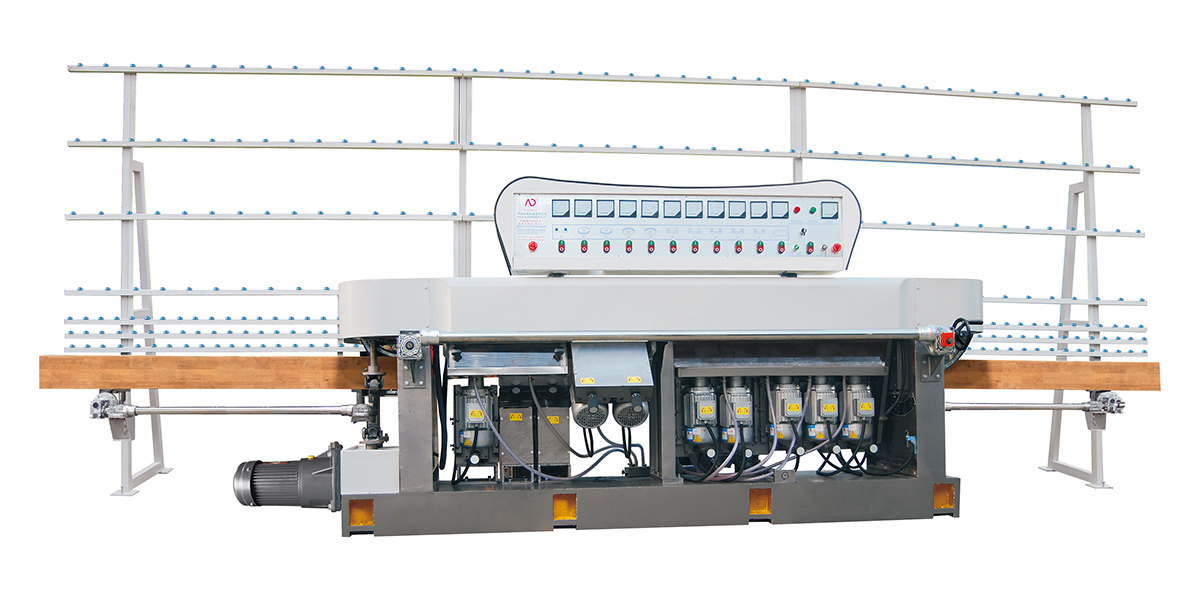

9 Motors 45 Degree Straight Line Edging Machine

- Product Information

The 9 Motors 45 Degree Straight Line Edging Machine is a highly accurate tool used for creating high quality glass edges. The machine, having nine motor functions, efficiently polishes straight lines at an angle of 45 degrees to guarantee smooth and precise finishes. ADZM9325A-45° glass straight line edging machine, suitable for grinding the straight edge of different szie and thickness flat glass. The coarse grinding, fine grinding, chamfering and polishing can be finished at one time. The #1-#5 grinders can be swung 0~45° as request to grinding straight edge with angle 45. Frequenay control of motor speed and working load can be adjusted smoothly by continuously variable mechanism transmission, also can adjust front rail to match different glass thickness. The machine is equipped with automatic clamping system and voltage stabilizing system. With easy operation, high precision and efficiency, this machine becomes one of indispensable equipment for glass procession. Specializing in the production of high-quality machinery, we are particularly proud of our China 45 degree straight line edging machine manufacturer, which exemplifies our commitment to excellence.

Straight Line Edging Machine Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADZM9325A-45° |

| Voltage | 380V/50Hz |

| Power | 22kw |

| Glass thickness | 3-25mm |

| Feeding speed | 0.5-7m/min |

| Min size | 80×80mm |

| Weight of machine | 2700kg |

| Overall size | 7200×2500×1100mm |

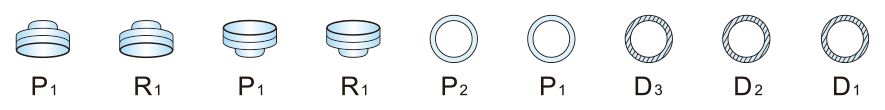

Straight Line Edging Machine Position of Wheels:

Straight Line Edging Machine Details:

1. CE machine & CE certification, PLC control system and digital displayer available.

2. Heavy duty foundation & beams: cast steel,annealing treatment.

3. Electric device: SIEMENS, Schneider or Delixi electrical optional.

4. ABB, XINDONGYA, motor optional. 380V/50Hz, 380V/60Hz, 220V/60Hz, 400V/50Hz, 415V/50Hz, optional.

5. Thicken chain transmission system, can loading 600kg big size thick glass. Beveling machine equipt synchronous belt PU chain transmission system.

6. Various high quality import grinding wheels. Suit for grind mirror, mosica, spell mirror, low-e glass, float glass, laminated glass, tempered glass, etc.

Straight Line Edging Machine Features:

Efficient grinding:

9 motors work together, with strong grinding power, which can quickly complete the rough grinding, fine grinding, chamfering and polishing processes of glass, greatly shorten the processing cycle, improve production efficiency, and meet the high output needs of glass processing companies.

Flexible angle adjustment:

The first five grinding heads of the 9 Motors 45 Degree Straight Line Edging Machine can swing freely from 0 to 45°, accurately adapting to the 45° edge grinding requirements of different glasses. Whether it is small or large size glass, the angle can be flexibly adjusted to ensure the grinding effect, providing diversified solutions for glass processing.

Accurate speed regulation:

9 Motors 45 Degree Straight Line Edging Machine adopts variable frequency speed regulation technology, with a wide speed regulation range and stable speed change. During the grinding process, the feed speed and feed amount can be adjusted arbitrarily according to the glass material, thickness and processing requirements to achieve precise processing and ensure the stability of glass processing quality.

Strong adaptability:

The 9 Motors 45 Degree Straight Line Edging Machine has an adjustable front rail design, which can adapt to the processing of glass of different thicknesses. Glass from 3mm to 25mm thickness can be processed stably without frequent equipment replacement or adjustment of complex parameters, which enhances the versatility and practicality of the equipment.

High degree of automation:

The 9 Motors 45 Degree Straight Line Edging Machine is equipped with an automatic clamping system, which can firmly clamp the glass to ensure the stability of the processing process; the voltage stabilization system ensures that the voltage is stable during the operation of the equipment, avoiding the impact of voltage fluctuations on the processing accuracy and equipment life, realizing automatic processing, and reducing the intensity of manual operation.

Convenient operation:

The overall operation interface of the 9 Motors 45 Degree Straight Line Edging Machine is simple and intuitive, and the setting and adjustment of various parameters are convenient and fast. The reasonable layout of the equipment structure is convenient for operators to quickly get started, and it is easy to maintain, which improves the operability and maintenance efficiency of the equipment and reduces downtime.

High-precision processing:

During the design and manufacturing process, 9 Motors 45 Degree Straight Line Edging Machine strictly controls the precision, from the processing precision of mechanical parts to the accuracy of electrical control, to ensure the high precision of glass processing. The processed glass has smooth and flat edges and high dimensional accuracy, meeting the requirements of high-quality glass processing.

Stable and reliable:

High-quality motors, electrical components and mechanical parts are selected, and strict quality inspection and testing are carried out to ensure the stability and reliability of 9 Motors 45 Degree Straight Line Edging Machine under long-term operation. The sturdy body structure can withstand high-intensity processing tasks and reduce the equipment failure rate.

Straight Line Edging Machine Application:

Architectural glass processing:

9 Motors 45 Degree Straight Line Edging Machine can be used for straight edge grinding and chamfering of architectural door and window glass, curtain wall glass, etc., meeting the strict requirements of the construction industry for glass appearance quality and dimensional accuracy, providing high-quality glass processing solutions for construction projects, and ensuring the beauty and sealing of glass after installation.

Furniture glass processing:

In the field of furniture glass, such as the production of glass coffee tables, glass cabinet doors and other products, 9 Motors 45 Degree Straight Line Edging Machine can efficiently complete the fine processing of glass edges, making the edges of glass furniture smooth and burr-free, improving the overall quality and service life of furniture, and enhancing the market competitiveness of products.

Automotive glass processing:

9 Motors 45 Degree Straight Line Edging Machine is suitable for edge grinding and chamfering of automobile windshields, window glasses, etc., ensuring the flatness and smoothness of automobile glass edges, improving the assembly accuracy and sealing performance of automobile glass, ensuring the safety and comfort of automobile driving, and meeting the high standards of the automotive industry for glass processing.

Electronic glass processing: For glass parts in electronic devices, such as mobile phone screen glass, display glass, etc., the 9 Motors 45 Degree Straight Line Edging Machine can perform high-precision straight edge grinding and chamfering to ensure the dimensional accuracy and appearance quality of glass parts, meet the electronics industry's demand for precision in glass processing, and help improve the quality of electronic products.

Decorative glass processing: In the field of decorative glass, such as glass partitions, glass curtain wall decoration, etc., the 9 Motors 45 Degree Straight Line Edging Machine can process exquisite glass edges, add beauty to decorative glass, enhance the decorative effect, meet the personalized needs of interior decoration and architectural exterior decoration for glass processing, and create a unique visual effect.

Craft glass processing: 9 Motors 45 Degree Straight Line Edging Machine is used in the production of glass crafts, such as glass ornaments, glass lamps, etc. It can finely process the glass edges, making the appearance of the crafts more refined and beautiful, enhancing the artistic value and appreciation of the crafts, and providing professional processing equipment support for the glass crafts industry.

Straight Line Edging Machine Maintenance:

Daily cleaning:

After each processing, the glass debris and dust on the surface and working area of 9 Motors 45 Degree Straight Line Edging Machine should be cleaned in time. Use a soft brush or clean cloth to wipe the equipment to prevent debris accumulation from affecting the equipment's operating accuracy and processing quality. Clean the filter device inside the equipment regularly to ensure smooth ventilation and prevent dust from entering the electrical components and affecting the equipment's performance.

Motor maintenance: Regularly check the operating status of the 9 Motors 45 Degree Straight Line Edging Machine motor and observe whether the motor has abnormal noise, vibration or overheating. Keep the motor surface clean to avoid dust and oil accumulation. According to the requirements of the motor manual, regularly replace the lubricating oil or grease to ensure good lubrication of the motor and extend the service life of the motor. Check whether the fixing bolts of the motor are loose. If they are loose, tighten them in time to prevent the motor from shifting and affecting the processing accuracy.

Grinding head maintenance:

Check the wear of the grinding head of 9 Motors 45 Degree Straight Line Edging Machine and replace the severely worn grinding head in time to ensure the grinding effect. Clean the glass residue on the grinding head regularly to prevent the residue from affecting the grinding performance of the grinding head. Check whether the fixing device of the grinding head is firm. If it is loose, adjust it in time to ensure the stability of the grinding head during processing. According to the material and thickness of the processed glass, reasonably select the model and particle size of the grinding head to achieve the best grinding effect.

Electrical system inspection:

Regularly check whether the wiring of the 9 Motors 45 Degree Straight Line Edging Machine electrical system is firm, and whether there is looseness, virtual connection or short circuit. Check the working status of electrical components, such as whether contactors, relays, etc. are normally attracted and released. If there is any abnormality, they should be replaced in time. Clean and dust the electrical control system regularly to prevent dust accumulation from affecting the heat dissipation and performance of electrical components. Check whether the grounding device of the equipment is in good condition to ensure the safety of the equipment during operation.

Lubrication system maintenance:

Check whether the oil level of the 9 Motors 45 Degree Straight Line Edging Machine lubrication system is normal, and regularly add or replace the lubricating oil. Check whether the lubrication pipeline is unobstructed, whether there is blockage or leakage, and if there is any problem, it should be repaired in time. Regularly check the working status of the oil pump, oil nozzle and other components of the lubrication system to ensure the normal operation of the lubrication system, provide good lubrication for the mechanical parts of the equipment, reduce wear and extend the service life of the equipment.

Regular calibration and debugging:

Regularly calibrate the processing accuracy of the 9 Motors 45 Degree Straight Line Edging Machine, check whether the parameters such as the swing angle, feed amount, and feed speed of the grinding head meet the requirements, and adjust them in time if there are deviations. According to the use of the equipment, regularly debug the mechanical parts of the equipment, such as adjusting the spacing of the grinding head and the parallelism of the guide rail, to ensure that the equipment is in the best operating state and ensure the stability and consistency of the processing quality.