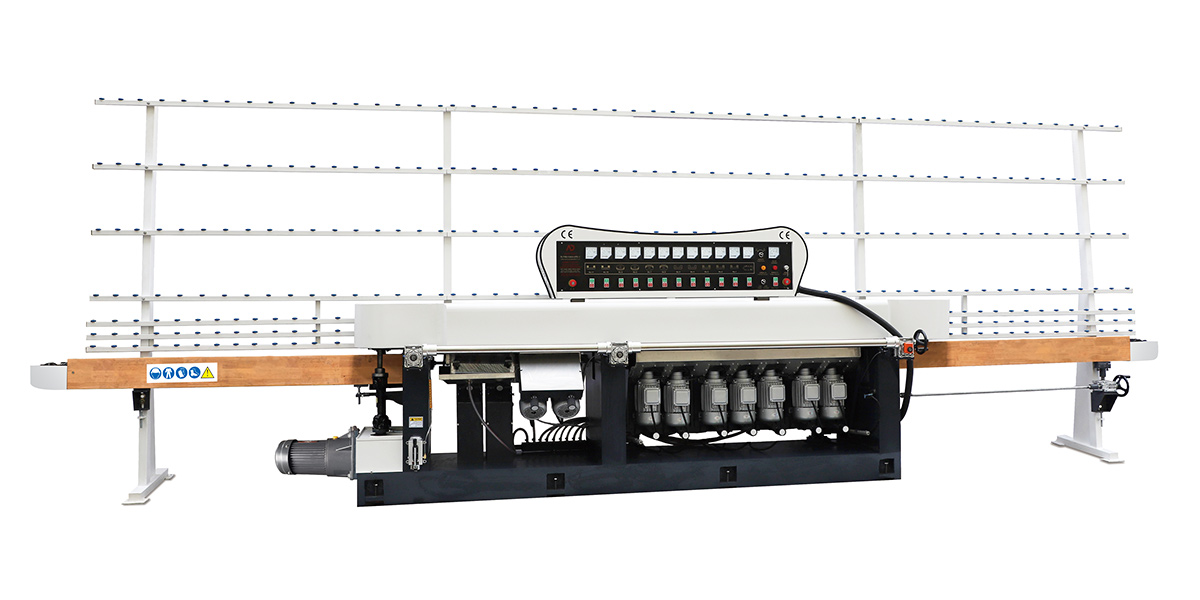

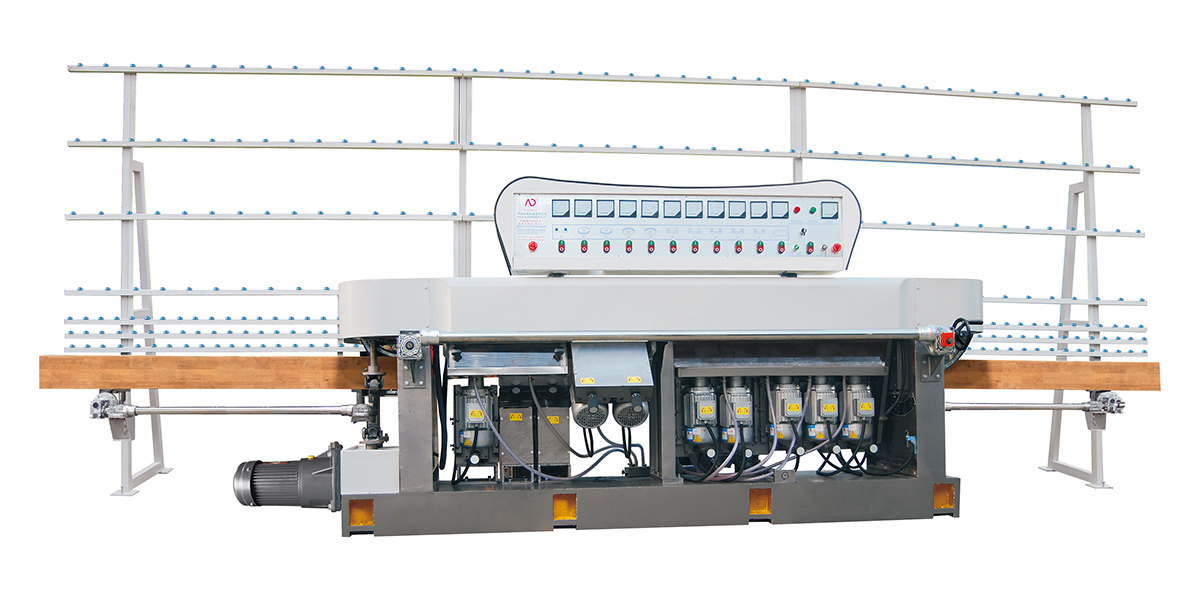

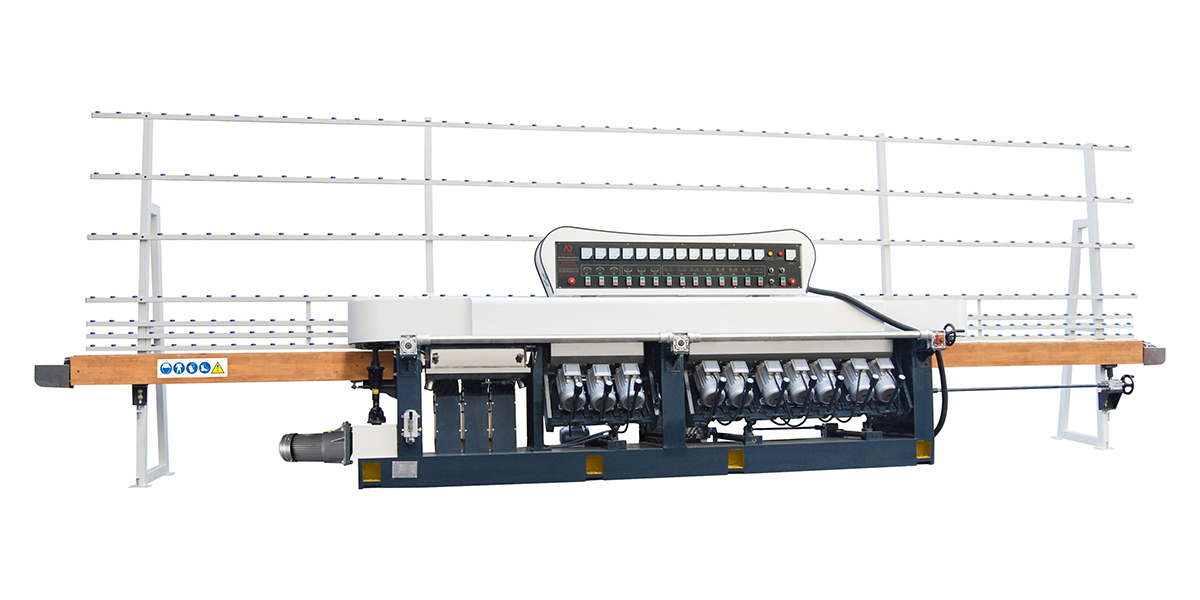

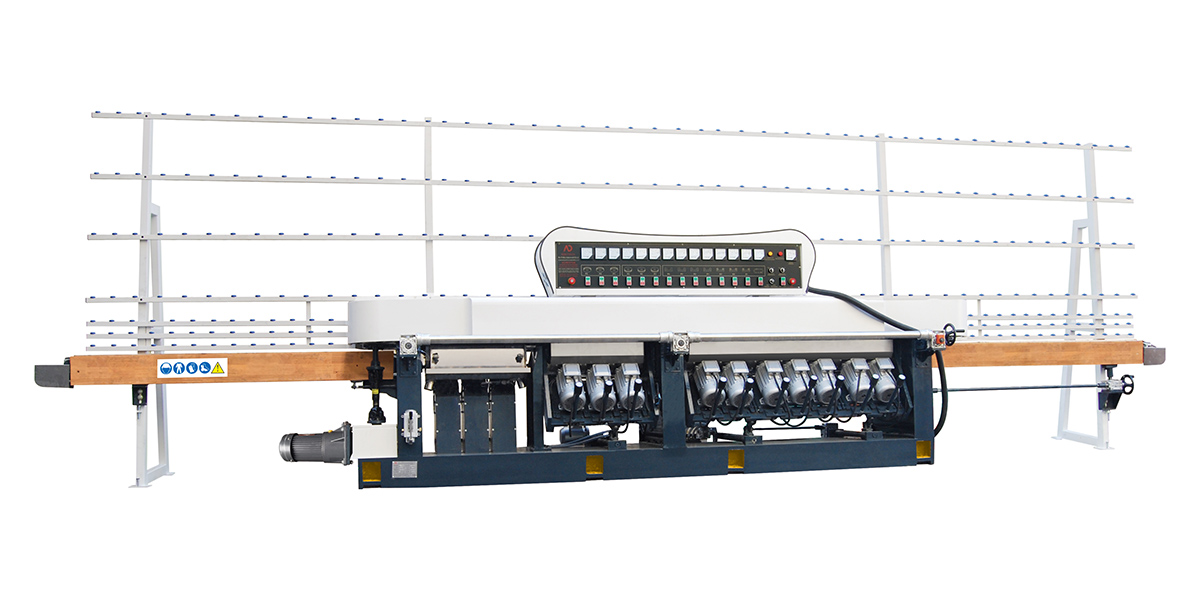

Chain Type Glass Edging Machine

- Product Information

The 13 motors 45° chain type Glass Edging Machine is a precision tool designed for efficient glass processing. ADZM733 glass 45° edging machine. Suitable for glass straight line edging machine and chamfering.The first 7 motors and 3 chamfering motors can change angle from 0°-45°, while the first 7 motors swing to 45°, rhe 3 chamfering motors can swing to 0° for bottom edge edging. Machine using PLC control the glass thinckness, glass angle and height of loading & unloading guide.lt using touch screen PLC or manual and variable frequency control motor. lt have high precision and good polishing effect. It’s a necessary edging machine in high quality glass processing. As a premier Chinese Chain Type Glass Edging Machine exporter, we pride ourselves on our advanced manufacturing capabilities and rigorous quality control processes.

Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADZM733 |

| Voltage | 380V/50Hz |

| Power | 30kw |

| Bevel angle | 0°-45° |

| Max bevel width | 40mm |

| Glass thickness | 3-25mm |

| Feeding speed | 0.5-7m/min |

| Min size | 80×80mm |

| Weight of machine | 3400kg |

| Overall size | 8500×2400×1300mm |

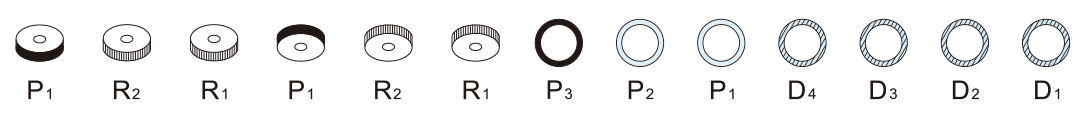

Position of Wheels:

Chain Type Glass Edging Machine is a high-precision equipment for glass edge processing, which is widely used in the glass processing industry, especially in straight edge grinding, beveling and chamfering. Unlike other types of glass edge processing machines, the chain type glass edge processing machine uses a chain transmission system to push the glass plate to move in the processing area, and grinds and trims the glass edge through a high-speed rotating grinding wheel to ensure that the edge is smooth and neat and meets product quality standards.

Chain type glass edge processing machine is usually used to process thin glass and thick glass, and can process various types of edge shapes, such as straight edges, beveled edges, rounded edges, etc. Its high precision and high efficiency make this equipment occupy an important position in the glass processing industry, especially in high-volume production lines, which can realize automatic operation, reduce manual intervention and improve production efficiency.

2. Detailed explanation of product features

1. Chain transmission system, stable and efficient glass conveying

One of the core features of the chain type glass edge processing machine is its chain transmission system, which can smoothly and efficiently convey glass plates during work. The chain accurately delivers the glass sheet to the processing area through precise rollers and bracket devices, and ensures that the position of the glass is always stable during the processing.

The chain has high transmission accuracy and adjustable transmission speed, usually in the range of 2–8 m/min. In addition, the adjustment of the chain system can adapt to glass of different thicknesses and sizes, ensuring that the equipment can meet different production needs. Compared with traditional slide or roller transmission, this transmission method is more efficient and stable, avoiding the misalignment or shaking of the glass during the processing.

2. Multiple sets of grinding wheels to meet different processing requirements

Chain-type glass edge processing machines are usually equipped with 2 to 6 sets of grinding wheels, each set of grinding wheels has different functions, such as rough grinding, fine grinding, chamfering, beveling, etc. The diameter of each set of grinding wheels is generally 150mm–300mm, and the speed can reach 3000–6000 RPM. Different sets of grinding wheels achieve ideal processing effects by accurately adjusting the angle and height.

According to the thickness of the glass and the processing requirements, the angle of the grinding wheel can be adjusted, usually in the range of 0°–45°, to meet various types of edge processing requirements. In order to ensure high-precision grinding, the equipment can also automatically adjust the pressure and speed of the grinding wheel according to the material of the glass to achieve the best grinding effect.

3. Automatic control system to improve processing efficiency

The chain-type glass edge processing machine is equipped with a PLC automatic control system, which can accurately control the parameters of each processing process, including the speed, angle, pressure of the grinding wheel and the transmission speed of the glass. This automatic control system can achieve precise edge processing, reduce manual intervention and improve production efficiency.

The system is characterized by high response speed and multi-tasking capabilities. During the production process, the operator only needs to set the parameters through the touch screen interface, and the equipment can automatically complete different types of glass edge processing tasks. The PLC system usually has a fault self-diagnosis function, which is convenient for the operator to promptly discover and solve equipment failures and ensure the smooth operation of the production line.

4. Efficient cooling system to extend the service life of the equipment

The heat generated during the glass processing process will affect the grinding wheel and the glass itself. Therefore, the chain-type glass edge processing machine is equipped with an efficient cooling system. The system usually uses water-based coolant or oil-based coolant, and sprays the coolant evenly on the grinding wheel and glass surface through multiple nozzles to prevent glass breakage or excessive wear of the grinding wheel due to high temperature.

The flow rate of the coolant is generally 3-6 L/min, and can be adjusted as needed to ensure that each grinding wheel can be fully cooled during processing. This cooling system can greatly increase the service life of the grinding wheel, reduce thermal deformation during glass processing, and improve processing accuracy.

5. Durable mechanical structure, reduce vibration and noise

The body of the chain-type glass edge processing machine is usually made of high-strength cast iron material with strong earthquake resistance. This sturdy structure can effectively reduce the vibration generated during high-speed processing and maintain the smooth operation of the equipment, thereby ensuring processing accuracy and glass quality.

In addition, the design of the equipment fully considers noise control, and uses shock-absorbing pads or sound insulation materials, which can effectively reduce noise when running at high loads. This design not only improves the working environment of the factory, but also reduces the interference of vibration and noise to operators.

6. High-precision glass positioning system to ensure processing accuracy

Chain-type glass edge processing machines are usually equipped with a high-precision positioning system, which uses laser positioning sensors or photoelectric sensors to accurately control the feeding and discharging positions of the glass. This positioning system can ensure that the glass remains stable during processing without displacement or misalignment, ensuring the accuracy of each edge processing.

The system can adjust the input speed and direction of the glass through a digital interface to ensure the edge consistency of each glass processing.

III. Application scenario analysis

1. Construction and decoration industry

Chain-type glass edge processing machines are widely used in the production of architectural glass, especially in projects such as glass curtain walls, window glass, skylights, and transparent partitions. Through high-precision edge grinding and trimming, chain-type equipment can make the glass meet the requirements of beauty and safety, increase its compressive strength, reduce the sharp edges of the glass, and improve the convenience of installation.

For example, glass windows in modern commercial buildings and high-end residences usually require fine edge processing, not only for the beauty of the appearance, but also to ensure that the glass will not cause harm to installers and residents.

2. Furniture and Home Decoration

Chain-type glass edge processing machines are also widely used in the furniture and home decoration industries, especially in the production of glass coffee tables, tabletop glass, bookcase glass, cabinet door panels and decorative mirrors. The processed glass edges are smooth and have no sharp corners, which not only improves the appearance of the furniture, but also improves the safety of the product.

For example, when making modern-style dining tables or coffee tables, chain-type glass edge processing machines can accurately round corners, making the glass surface smoother and flawless, enhancing its beauty and service life.

3. Automobile Industry

Chain-type glass edge processing machines also play an important role in the production of automotive glass, especially for the processing of car windows, windshields and rearview mirrors. The processed glass can not only improve its compressive strength, but also optimize its fit with the car body and improve the safety of the car.

During the production process, the edges of the glass need to be finely chamfered and trimmed to ensure smooth fit during installation and reduce injuries to installers caused by sharp edges.

4. Precision glass and optical industry

In the processing of precision glass and optical glass, the chain-type glass edge processing machine can accurately control the angle and smoothness of each edge to ensure product quality. These products are usually used in optical instruments, lighting equipment, camera lenses and other fields. The precision and smoothness of the edge directly affect the performance and appearance of the final product.