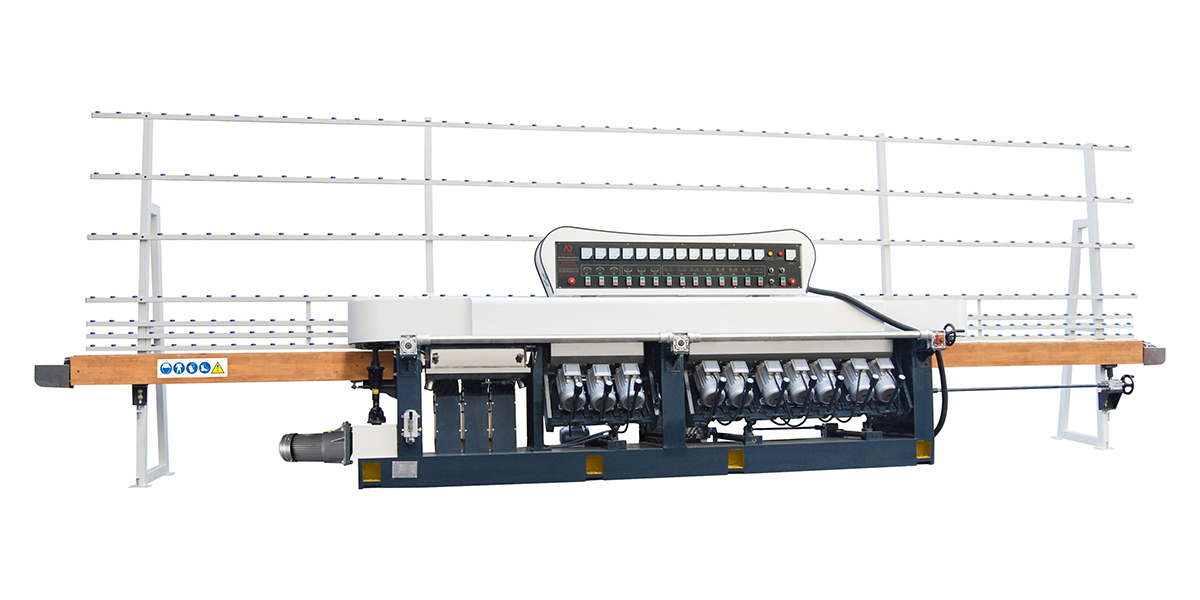

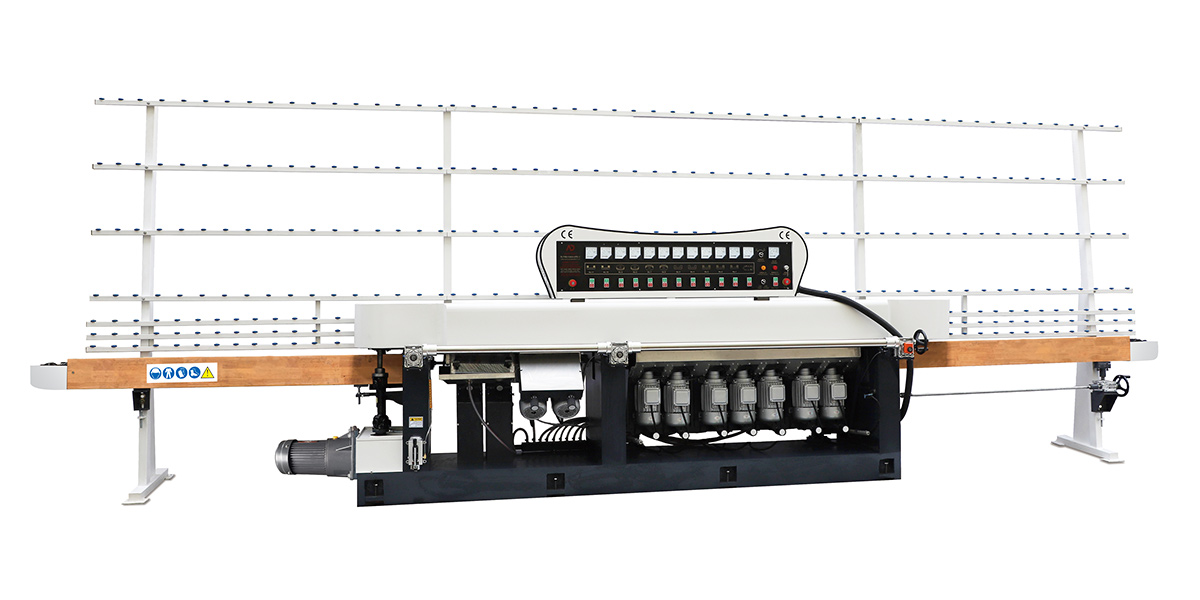

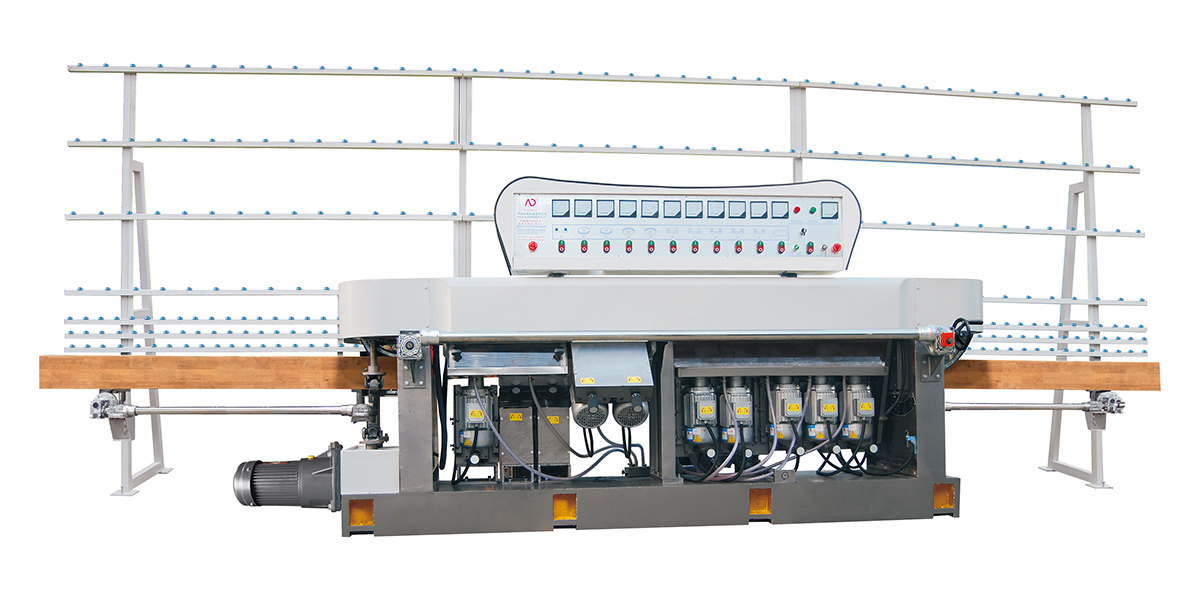

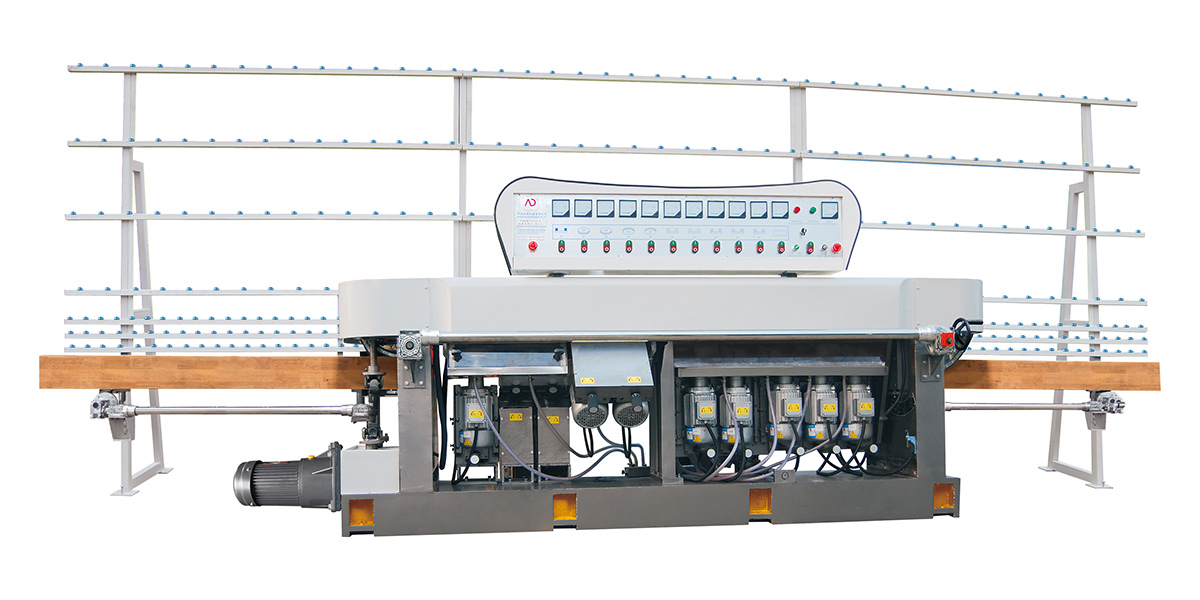

PLC Control 10 Motors 45 Degree Edging Machine

- Product Information

ADZM11325A-45° glass straight line edging machine, suitable for grinding the straight edge of different size and thickness flat glass. The coarse grinding, fine grinding, chamfering and polishing can be finished at one time. The #1-#5 grinders can be swung 0~45° as request to grinding straight edge with angle 45°. Frequenay control of motor speed and working load can be adjusted smoothly by continuously variable mechanism transmission, aslo can adjust front rail to match different glass thickness. The machine is eauipped with automatic clamping system and voltage stabilizing system. With easy operate, high precision and efficiency, this machine becomes one of indispensable equipment for glass procession. As a trusted China 10 motors 45 degree edging machine supplier, we are committed to innovation and excellence, providing our clients with cutting-edge solutions that meet the highest standards of performance and reliability.

Technical Specifications:

| Item | Technical Specifications |

| Model Number | ADZM10325A-45° |

| Voltage | 380V/50Hz |

| Power | 24kw |

| Glass thickness | 3-25mm |

| Feeding speed | 0.5-7m/min |

| Min size | 80×80mm |

| Weight of machine | 3200kg |

| Overall size | 7300×2500×1100mm |

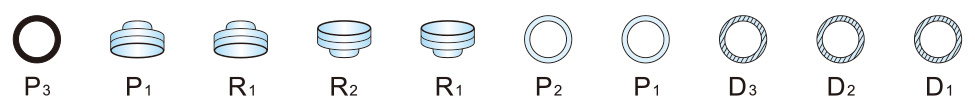

Position of Wheels:

The PLC Control 10 Motors 45 Degree Edging Machine is a high-precision CNC equipment developed specifically for the glass deep processing industry. It integrates PLC (Programmable Logic Controller) and 10 sets of independently driven grinding units, and can complete glass 45 ° beveled edge, chamfering, polishing, and safe fillet processing in one go. The equipment supports the processing of float glass, tempered glass, Low-E coated glass, and ultra white glass with a thickness of 3-19mm. The maximum processing size can reach 3200mm × 2200mm, with an angle accuracy of ± 0.1 °. The processing efficiency is 40% higher than traditional 6-axis equipment, and it is suitable for large-scale production in fields such as building curtain walls, furniture panels, bathroom glass, and solar photovoltaic modules.

2、 Core Features and Professional Data

PLC intelligent control system

Control architecture: Using Siemens S7-1500 series PLC as the core, equipped with Codesys 3.5 programming platform, supporting dual mode programming of ladder diagram (LAD) and structured text (ST), with logic operation speed ≤ 0.1m/thousand instructions, ensuring multi axis collaborative response without delay.

Human Computer Interaction: Equipped with a 12 inch industrial grade capacitive touch screen with a resolution of 1280 × 800, supporting multi language interface switching (Chinese/English/German), operation response time ≤ 0.3 seconds, capable of storing 200 sets of processing parameters (including glass thickness, angle, speed, etc.), and changeover time ≤ 10 minutes.

Data traceability: Built in 128GB industrial grade storage module, real-time recording of processing quantity, grinding wheel life, fault codes and other data, supports USB/Ethernet export, meets ISO 9001 quality traceability requirements.

Multi axis precision grinding technology

Axis configuration: 10 sets of servo motors are independently driven (rated power 1.2-2.5kW/axis), and synchronous communication at 0.02ms level is achieved through Profinet bus. The cumulative processing error of four stages of rough grinding, fine grinding, polishing, and chamfering is ≤± 0.08mm (ISO 230-2 standard).

Angle accuracy: 45 ° oblique edge processing angle deviation ≤ ± 0.1 °, chamfer width 1-6mm continuously adjustable, corner radius R0.5-R2mm optional, meeting the requirements of the EU EN12600 safety glass standard for edge strength.

Sports performance: X/Y/Z three-axis positioning accuracy ± 0.03mm, repeat positioning accuracy ± 0.015mm, maximum feed rate 25m/min (coarse grinding section), 12m/min (fine grinding/polishing section), single shift production capacity (8 hours) up to 1000-1300 ㎡ (taking 5mm glass as an example).

Modular Art Chain Design

Rough grinding unit: 4 sets of diamond grinding wheels (particle size 80 # -150 #), linear speed 2500-3000r/min, single-sided grinding amount ≤ 2.0mm, surface roughness Ra ≤ 3.5 μ m, quickly remove glass cutting burrs.

Precision grinding unit: 3 sets of resin bonded diamond grinding wheels (particle size 280 # -400 #), linear speed 2000-2400r/min, edge straightness ≤ 0.12mm/m after processing, verticality error ≤ ± 0.2 °, providing high-quality base for polishing.

Polishing unit: 2 sets of wool felt+cerium oxide polishing wheels (particle size W7-W3), adjustable pressure of 0.15-0.4MPa, surface glossiness after processing ≥ 85GU (60 ° angle detection), light transmittance loss ≤ 0.5%, meeting high-end display needs.

Safe corner unit: 1 set of programmable corner grinding wheels, controlled by PLC for corner radius (R0.5-R2mm), with a 25% increase in edge impact strength after processing (tested according to ASTM C1048 standard).

Adaptive machining technology

Thickness compensation: Real time monitoring of glass thickness (accuracy ± 0.02mm) is achieved through a laser thickness gauge, and the PLC automatically adjusts the feed rate of the grinding wheel (compensation range ± 0.8mm), reducing the edge breakage rate to ≤ 0.4%.

Pressure closed-loop control: The pressure sensor (range 0-1MPa, accuracy ± 0.005MPa) is linked with the PLC to dynamically adjust the grinding pressure (0.1-0.6MPa) according to the glass hardness, ensuring processing consistency.

Energy consumption optimization: Equipped with intelligent sleep mode, the motor power is reduced by 60% when unloaded, and the comprehensive energy consumption is ≤ 10kW · h/100 ㎡ (calculated based on 5mm glass processing), saving 30% energy compared to traditional equipment.

Safety and Environmental Design

Dust recovery system: Adopting three-stage filtration technology (primary cyclone separation+medium efficiency filter cartridge+HEPA H14), the filtration efficiency is ≥ 99.995%, the dust concentration in the processing area is ≤ 1.5mg/m ³ (in accordance with GBZ 2.1-2019 standard), and the noise in the operating area is ≤ 72dB (A).

Emergency stop protection: The entire machine is equipped with 6 sets of distributed emergency stop buttons, with a response time of ≤ 40ms and an emergency braking distance of ≤ 40mm (at a feed rate of 25m/min), in compliance with ISO 13849-1 safety standards.

Protection level: IP55 protection for electrical cabinets, IP67 protection for motors, suitable for environmental temperatures ranging from -10 ℃ to 50 ℃, MTBF (mean time between failures) ≥ 7500 hours.

3、 Application scenarios

Building curtain walls and door and window glass

45 ° Joint Processing: Provide high-precision 45 ° beveled edges for large commercial building curtain wall glass, with joint gaps ≤ 0.3mm, meeting the requirements of JGJ 102-2003 "Technical Code for Glass Curtain Wall Engineering" for sealing and aesthetics.

Energy saving Low-E glass: During the processing, the coating peeling rate is ≤ 0.15%, ensuring that the K value (heat transfer coefficient) of the insulating glass is ≤ 1.6W/(m ² · K), improving building energy efficiency.

Furniture and bathroom glass

Customized design: Processing irregular sizes (such as trapezoidal and diamond) for dining table glass and bathroom partitions, supporting a 45 ° beveled edge+R1.5mm rounded corner combination process, with a surface defect rate of ≤ 0.08% (tested according to ASTM D4828 standard).

High transparency polishing: Provides mirror level polishing for smart bathroom mirror glass, with a transmittance of ≥ 91% and haze of ≤ 1.2%, meeting high-end home needs.

Automotive and Photovoltaic Industry

Automotive sunroof glass: processed with a 45 ° curved beveled edge (in conjunction with a CNC bending machine), the chamfering strength meets the FMVSS 205 standard, and the impact energy resistance is ≥ 45J, ensuring driving safety.

Photovoltaic module glass: provides high transmittance polished edges for ultra white embossed glass, with a post processing edge breakage rate of ≤ 0.4% and a conversion efficiency loss of ≤ 0.15%, extending the lifespan of the module.